Aug. 01, 2025

The main differences between blast furnaces (BF) and electric arc furnaces (EAF) lie in their production methods and the raw materials they use. Blast furnaces primarily use iron ore and coal to produce iron, which is then refined into steel. EAFs, on the other hand, primarily use scrap steel and electricity to produce steel.

The production process of blast furnace mainly includes raw material preparation, furnace hearth material distribution, ignition preheating, air temperature control, smelting process, tapping and shutdown. Below, we will provide a detailed introduction one by one.

(1) Raw material preparation: Iron ore is the main raw material for smelting molten iron, and its quality and particle size have a significant impact on the smelting effect of blast furnaces. Iron ore needs to be processed through crushing, grading, washing, etc. to ensure that it meets production requirements. The crushed iron ore should meet the particle size requirements to avoid adverse effects on blast furnace smelting caused by particles that are too large or too small.

Coke preparation: Coke is an important energy and reducing agent for blast furnace smelting, and its quality and quantity directly affect the smelting effect of the blast furnace. Coke needs to undergo carbonization, calcination, and mixing treatments to improve its combustion efficiency and furnace temperature. Limestone preparation: Limestone serves as a fluxing agent and plays a role in reducing the melting point of slag and improving its flowability during the blast furnace smelting process. Limestone needs to be crushed, screened, and processed to meet production requirements.

(2) Hearthstone feeding refers to the process of feeding pre prepared raw materials into the blast furnace cavity in a certain proportion. In blast furnace operation, it is necessary to consider the ratio and feeding method of various raw materials to achieve the best smelting effect. Normally, iron ore and coke are mixed in a certain proportion and loaded into the hopper at the upper part of the blast furnace, and then evenly distributed into the furnace hearth through a material distribution device.

(3) After the ignition preheating furnace is completed, the ignition preheating operation needs to be carried out. Ignition preheating refers to the combustion of raw materials in the furnace to gradually raise the temperature inside the furnace to the required temperature for smelting. The ignition preheating process usually includes stages such as initial ignition, secondary ignition, and normal ignition. In blast furnace operation, attention should be paid to controlling the ratio of oxygen and fuel for ignition to ensure normal ignition.

(4) After the ignition preheating is completed, air temperature control is required. Energy needs to be provided through combustion inside the blast furnace, and wind is the key to providing the oxygen required for combustion. During the operation of the blast furnace, it is necessary to control the temperature of the air according to the requirements of the smelting conditions. Normally, the higher the temperature of the wind, the higher the temperature inside the furnace. By adjusting the air temperature, the temperature inside the blast furnace and the rate of smelting reaction can be controlled.

(5) The smelting process is the core link of blast furnace production and a key step in steel production. In the blast furnace, iron ore undergoes a reduction reaction and is reduced to molten iron, while producing slag. During the smelting process, it is necessary to control parameters such as temperature, atmosphere, and pressure inside the furnace to ensure the smooth progress of the smelting reaction. In addition, it is necessary to treat the slag to improve its utilization value.

(6) Ironmaking is the ultimate goal of blast furnace operation and the final stage of the smelting process. During the production process, regular tapping operations are required to extract the molten iron from the furnace and perform cooling and purification treatment. The tapping operation needs to consider factors such as the temperature, speed, and cleanliness of the molten iron to ensure the production of steel products that meet the requirements.

(7) When the shutdown operation cycle of the blast furnace is over or maintenance is required, the shutdown operation needs to be carried out. Shutdown refers to suspending the smelting process of a blast furnace for cooling, cleaning, and maintenance work. During the shutdown period, it is necessary to inspect, maintain, and repair the blast furnace to ensure its normal operation and extend its service life.

The characteristics of blast furnace production technology include high temperature, high pressure, and high energy consumption.

Therefore, it is necessary to strictly control various parameters during the smelting process to ensure the smelting effect and product quality. The blast furnace production adopts continuous operation mode, which has high production efficiency, but also puts forward high requirements for equipment maintenance and operation level. The slag and waste gas generated during the blast furnace production process need to be properly treated to reduce environmental pollution and resource waste.

As the core equipment of the entire steel plant, blast furnace has a significant impact on the quality and output of steel products through its production process and technology. By providing a detailed introduction to the production process and technology of blast furnaces, as well as displaying relevant graphics and text, this article aims to help readers better understand and grasp the entire process of blast furnace production in steel mills. At the same time, it also reminds readers to pay attention to environmental protection and resource utilization issues in the production process of blast furnaces, promoting the sustainable development of the steel industry.

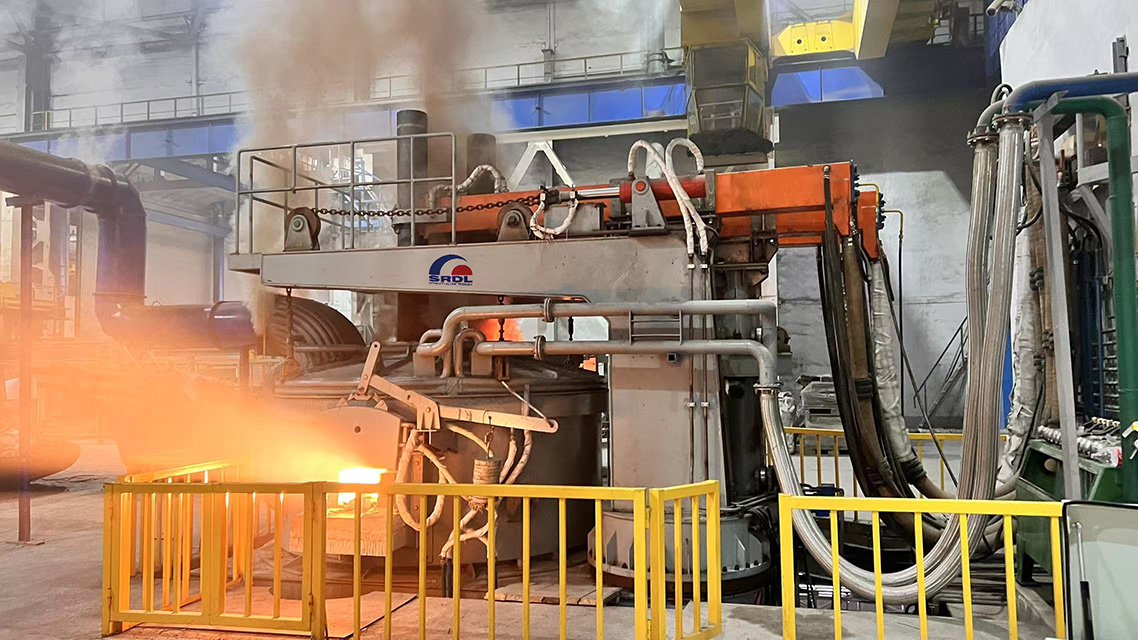

The working principle of an electric arc furnace (EAF) is mainly based on the high temperature generated by arc discharge to melt metal.

1. Configuration of electrodes and metal materials: Metal materials, usually including scrap steel, alloys, etc., are placed inside the furnace of an electric arc furnace. There are three graphite or metal electrodes on the top or side walls, which are used to generate electric arcs.

2. Formation of arc: When the electrode comes into contact with or approaches the metal material, current flows into the metal material through the electrode, forming an arc. The high temperature generated by the arc can reach over 3000 ℃, enough to melt the metal.

3. Melting process: The high temperature generated by the arc rapidly melts the metal material, forming a molten pool. As the melting process progresses, more metal material is added to the melt pool.

4. Chemical reactions and alloying: During the melting process, various alloy materials can be added to adjust the chemical composition of the steel. Meanwhile, electric arc furnaces can use oxygen guns for oxidation reactions to remove harmful elements such as sulfur and phosphorus.

5. Temperature control: By adjusting the position of the electrode and the current intensity, the temperature inside the furnace can be controlled to ensure temperature stability during the melting process.

6. Refining and steelmaking: After smelting is completed, refining can be carried out by adjusting the electrode position and controlling the cooling process to adjust the chemical composition and temperature of the molten steel. Finally, pour the melted steel into the ladle to complete the steelmaking process.

Electric arc furnaces are widely used in the steel industry due to their high efficiency and flexibility, especially in the production of high-quality steel and alloy steel. It can reduce production costs and improve resource utilization by using scrap steel as raw material.

An electric arc furnace is a device that uses the high temperature of an electric arc to melt metal. The main principle is to apply a high-voltage power source to the electrode, generate arc light, and form arc combustion between the electrode and the molten metal, thereby heating the metal to a molten state.

The melting process of an electric arc furnace mainly includes three stages:

1. Arc generation and maintenance stage: When the voltage between the electrode and the metal increases to a certain extent, the electrons on the electrode begin to accelerate and collide with the metal surface, causing the metal to ionize and form ions, thereby forming an arc between the electrode and the metal.

2. Molten metal stage: As the arc energy increases, the metal surface begins to melt, gradually forming a certain amount of molten metal. At the same time, under the irradiation of arc light, a series of electrochemical reactions occur on the metal surface, causing pollutants and impurities to be oxidized, decomposed, and vaporized, thereby eliminating the gaseous impurities formed by the metal.

3. Stable melting and composition adjustment stage: When the volume of the metal melt reaches a certain level, the surface of the melt pool begins to stabilize. At this time, it is necessary to analyze and adjust the composition of the melt to obtain the desired alloy composition.

The advantage of electric arc furnace melting is that it can melt various metals without being limited by the shape and size of the raw materials; Being able to recycle and reuse waste metals, saving resources;

Strong controllability, able to accurately control the temperature and composition of the melt, suitable for the preparation of high-quality special steel.

But the disadvantages of electric arc furnace melting are also obvious, such as high energy consumption and difficulty in measuring furnace temperature.

In addition, the manufacturing and maintenance costs of electric arc furnace melting equipment are also relatively high.

Latest News

Characteristics of Scrap Aluminum Melting Furnace

Aug. 02, 2025

What is the Difference Between BF and EAF?

Aug. 01, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province