Jun. 30, 2025

The main differences between induction furnaces and electric arc furnaces are working principles, equipment investment, application areas, thermal efficiency, environmental protection and smelting characteristics. Induction furnaces use electromagnetic induction heating, which is suitable for small and medium-sized enterprises, environmentally friendly and highly thermally efficient; electric arc furnaces use arc high-temperature melting, with large equipment investment, suitable for large-scale enterprises, and great process flexibility.

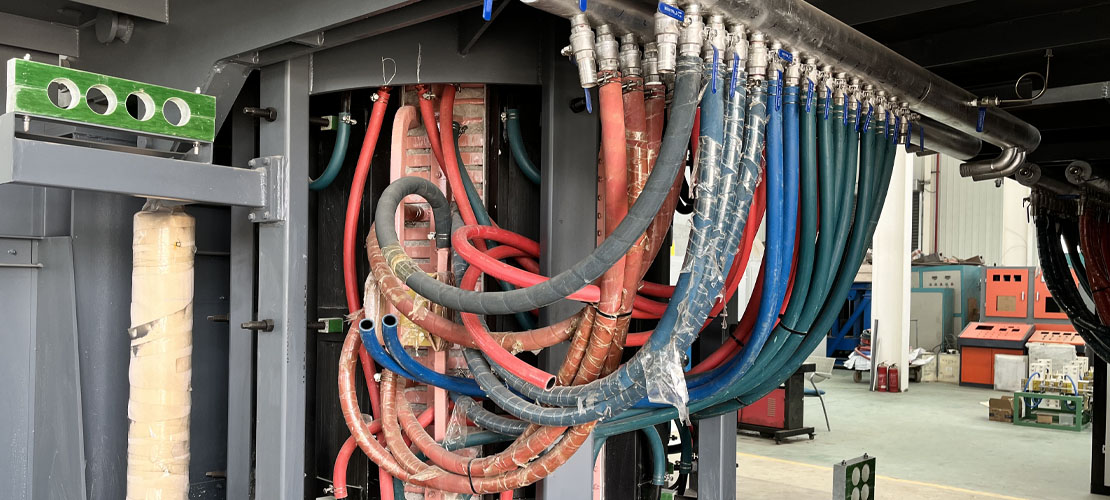

An induction furnace is an electric furnace that uses the induction electrothermal effect of materials to heat or melt materials. The AC power supply used in induction furnaces is of three types: industrial frequency (50 or 60 Hz), medium frequency (150-10,000 Hz) and high frequency (higher than 10,000 Hz). The main components of an induction furnace are sensors, furnace bodies, power supplies, capacitors and control systems. Under the action of the alternating electromagnetic field in the induction furnace, eddy currents are generated inside the material to achieve the effect of heating or melting. Induction furnaces are usually divided into induction heating furnaces and melting furnaces. Melting furnaces are divided into two types: core induction furnaces and coreless induction furnaces. Core induction furnaces are mainly used for melting and heat preservation of various cast iron, brass, bronze, zinc and other metals. They can use waste materials and have low melting costs. Coreless induction furnaces are divided into industrial frequency induction furnaces, triple frequency induction furnaces, generator set medium frequency induction furnaces, thyristor medium frequency induction furnaces, and high frequency induction furnaces.

1) It is easier to get high temperatures than fuel furnaces.

2) The material can be heated from the inside to increase its temperature.

3) It is easy to use in controlled atmosphere furnaces and vacuum furnaces.

4) Electric furnaces do not have the exhaust heat loss of fuel furnaces, so the thermal efficiency is high.

5) It is easy to control the temperature, which is convenient for remote control and fine adjustment.

6) It can be heated quickly.

7) Good operating performance and no pollution to the environment.

1) It is necessary to increase the cost of power distribution equipment.

2) The cost of electricity is high.

3) When the resistance heating temperature exceeds 1000℃, the refractory material may be conductive, and attention should be paid to insulation problems.

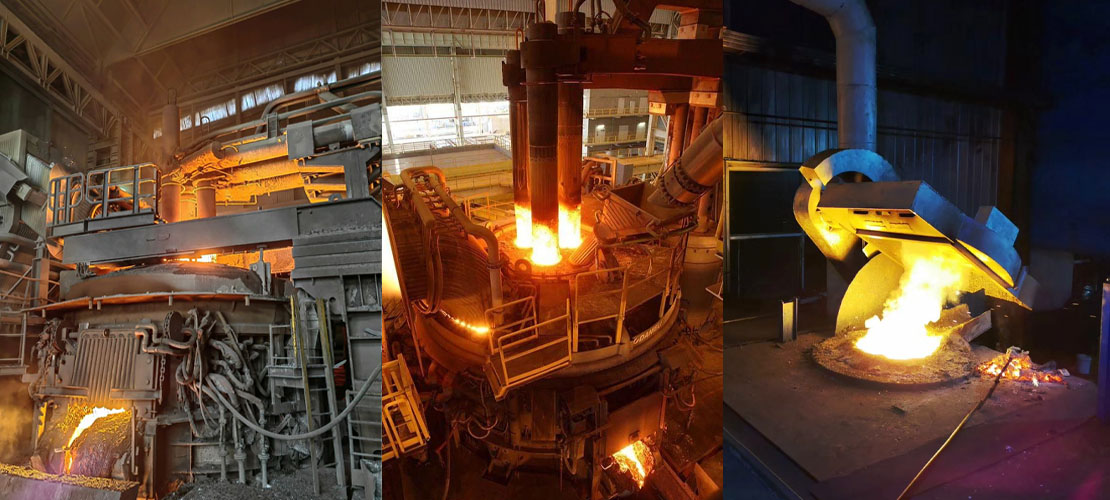

An electric arc furnace is an electric furnace that uses the high temperature generated by the electrode arc to melt ores and metals. When the gas discharge forms an arc, the energy is very concentrated, and the temperature in the arc zone is above 3000℃. For smelting metals, the electric arc furnace has greater process flexibility than other steelmaking furnaces, can effectively remove impurities such as sulfur and phosphorus, the furnace temperature is easy to control, the equipment occupies a small area, and is suitable for the smelting of high-quality alloy steel.

Arc furnace steelmaking is to input electrical energy into the electric arc steelmaking furnace through graphite electrodes, and use the arc generated between the electrode end and the charge as the heat source for steelmaking. The electric arc furnace uses electrical energy as the heat source and can adjust the atmosphere in the furnace, which is extremely beneficial for smelting steel containing more easily oxidized elements.

According to the arc form, arc furnaces can be divided into three-phase arc furnaces, consumable arc furnaces, single-phase arc furnaces and resistance arc furnaces.

Electric arc steelmaking furnaces are divided into ordinary power electric arc furnaces, high power electric arc furnaces and ultra-high power electric arc furnaces according to the transformer capacity per ton of furnace capacity.

The furnace body of an electric arc steelmaking furnace consists of a furnace cover, a furnace door, a steel tapping trough and a furnace body, and the furnace bottom and furnace wall are built with alkaline refractory materials or acidic refractory materials.

1) Electric arc steelmaking furnaces use electricity as the main energy source. Electric energy discharges and arcs with the charge through graphite electrodes, generating high temperatures of up to 2000 ~ 6000℃, and melts the scrap steel raw materials by arc radiation, temperature convection and heat conduction. For most of the time when the charge is melting, the high-temperature heat source is surrounded by the charge, and the heat loss caused by the high-temperature exhaust gas is relatively small, so the thermal efficiency is higher than other steelmaking equipment such as converters. In addition, electric heating can easily and accurately control the furnace temperature, and heating operations can be performed under any conditions such as oxidizing atmosphere or reducing atmosphere, normal pressure or vacuum according to process requirements.

2) The process flow of electric arc furnace steelmaking is short, the equipment is simple, the operation is convenient, it is relatively easy to control pollution, the construction investment is small, the land occupation is small, and it does not need to rely on a complex ironmaking system like converter steelmaking.

3) Electric arc furnace steelmaking has strong adaptability to furnace materials. It uses scrap steel as the main raw material, but it can also use solid and liquid iron-containing raw materials such as molten iron (blast furnace or cupola iron), sponge iron (DRI) or hot pressed briquettes (HBI), pig iron blocks, etc.

4) Because the atmosphere in the electric arc furnace steelmaking furnace is controllable, the slag adjustment or replacement operation is relatively easy, and the complex process operations of melting, decarburization, dephosphorization, degassing, inclusion removal, temperature control, composition adjustment (alloying) and other stages can be completed in the same operating system. Electric arc furnace steelmaking can be produced intermittently, and the production varieties can be flexibly changed within a certain range. In addition, modern electric arc furnaces can also use a large amount of auxiliary energy, such as heavy (light) oil, coal powder, natural gas, etc. Therefore, the electric arc furnace steelmaking process has strong adaptability, flexible operation and wide application.

5) The electric arc furnace can not only smelt high-quality steel with low phosphorus, sulfur and oxygen content, but also can be alloyed with a variety of elements (including easily oxidized elements such as lead, boron, vanadium, titanium and rare earth) to produce various high-quality steels and alloy steels, such as ball bearing steel, stainless acid-resistant steel, tool steel, electrical steel, heat-resistant steel, magnetic materials and special alloys.

The following table highlights all the key differences between induction furnace and electric arc furnace

| Parameter | Induction Furnace | Electric Arc Furnace |

|---|---|---|

| Principle | Induction furnaces produce high-temperature heat according to the principle of electromagnetic induction. | Electric arc furnaces produce heat by creating a high-temperature electric arc. |

| Energy efficiency | Induction furnaces have higher energy efficiency. | Electric arc furnaces are relatively less energy efficient than induction furnaces. |

| Operating temperature | Induction furnaces operate at relatively lower temperatures. | Electric arc furnaces operate at much higher temperatures. |

| Size | Induction furnaces are relatively smaller in size. | Electric arc furnaces have large size. |

| Suitability | Induction furnaces are best suited for small-scale operations. | Electric arc furnaces are suitable for heavy-duty and large-scale operations. |

| Noise | Induction furnaces produce very low noise. | Electric arc furnaces produce very high noise due to production of electric arc. |

| Initial cost | Induction furnaces have lower initial capital cost. | Electric arc furnaces have higher initial capital cost than induction furnaces. |

| Maintenance cost | Induction furnaces have higher maintenance cost. | Electric arc furnaces have lower maintenance cost. |

| Oxidation losses | In induction furnaces, the oxidation losses are very low. | In electric arc furnaces, the oxidation losses are high. |

| Electrode cost | Induction furnaces do not have electrodes, hence there is no electrode cost. | Electric arc furnaces involve electrode cost that is significantly high. |

| Energy consumption | Induction furnaces consume more electrical energy per ton due to low power factor. | Electric arc furnaces consume less electrical energy. |

| Impact on environment | Induction furnaces have relatively lower impacts on environment due to high energy efficiency. | Electric arc furnaces have more impacts on environment due to lower efficiency and high emissions. |

| Melting capacity | Induction furnaces have lower melting capacity. | Electric arc furnaces have higher melting capacity than induction furnaces. |

| Temperature control | Induction furnaces provide precise temperature control. | Electric arc furnaces do not provide temperature control like induction furnaces. |

| Applications | Induction furnaces are used for melting various non-ferrous metals like copper, aluminum, etc. | Electric arc furnaces are mainly used in iron and steel production and for melting scrap. |

Compared with electric arc furnaces, medium frequency furnaces have lower steelmaking costs and are suitable for small and medium-sized enterprises (small workshops). However, the steel produced by medium frequency furnaces has many impurities and high carbon content, so the purity is not high. If the requirements are not high, you can choose steel produced by medium frequency furnaces.

The volume of electric arc furnaces is generally more than 3 tons, so only enterprises of a certain scale will use electric arc furnaces, and the purity of the steel produced is relatively high. Electric arc furnaces use industrial frequency electricity, while medium frequency electric furnaces use medium frequency electricity. Compared with electric arc furnaces, induction furnaces have high thermal efficiency, thus achieving high production efficiency, flexible operation and low energy consumption.

In summary, induction furnaces and electric arc furnaces are types of electric furnaces widely used in various metal industries. Both furnaces use electricity to generate heat. In addition, induction furnaces and electric arc furnaces are more energy efficient than other traditional heating furnaces. However, as described in the table above, they are completely different in several aspects. The most significant difference between induction furnaces and electric arc furnaces is that induction furnaces generate heat through electromagnetic induction, while electric arc furnaces generate heat through an electric arc created between two electrodes.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province