Jun. 10, 2025

The water-cooled cable of the intermediate frequency induction furnace is a crucial component of the intermediate frequency induction furnace system. It is a special cable designed specifically for transmitting high currents while also having cooling functions. Medium frequency induction furnace water-cooled cable is a flexible current carrier with hollow water passage, used for high current heating equipment. It is not only responsible for transmitting the current generated by the intermediate frequency power supply to the induction coil, but also takes away the heat generated by the cable during transmission through the internal circulating cooling water, ensuring that the cable will not be damaged due to overheating and ensuring the normal operation of the electric furnace.

Medium frequency induction furnace water-cooled cables are widely used in processing techniques such as melting, forging, heat treatment (quenching), welding, bending, metal penetration, and rolling of ferrous metals (such as stainless steel, carbon steel, and alloy steel) and non-ferrous metals (such as copper and aluminum). It is an indispensable and important component in the medium frequency induction furnace system, which is of great significance for improving production efficiency and ensuring product quality.

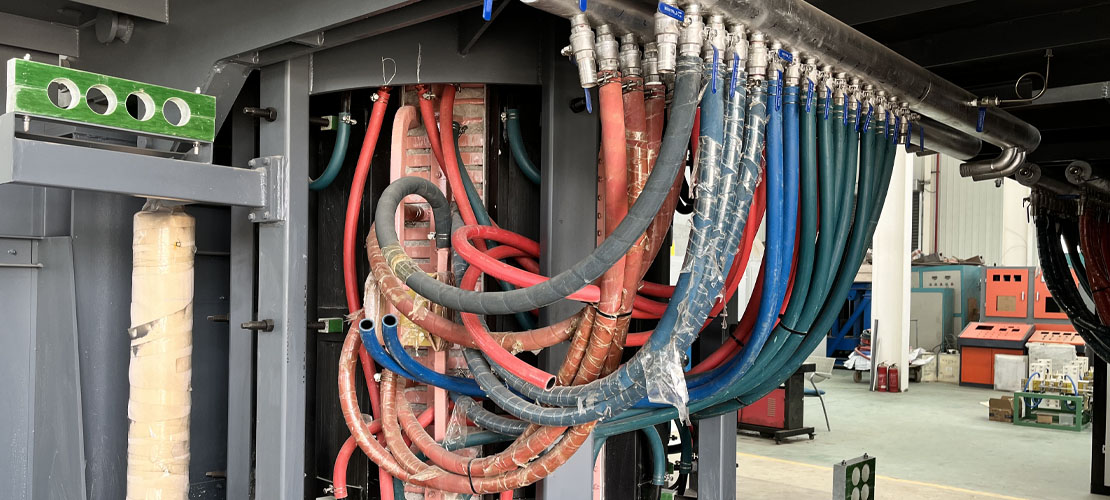

The medium frequency induction furnace cable adopts a water-cooled large section flexible current carrier, which is a special cable with hollow water passage used for high current heating equipment. It is mainly composed of an outer sleeve, soft wire, clamp, electrode head, water nozzle and other components selected and combined.

1. Water cooled cable jacket: a synthetic rubber tube with a water pressure resistance of>0.8MPA, a breakdown voltage resistance of over 3000V, a reinforced clamping layer, and the ability to withstand cooling water pressure and mechanical stress during operation.

2. Soft wire (copper stranded wire) for water-cooled cables: Using enameled wire for water-cooled cables results in high energy transmission efficiency. Due to the insulation between each enameled wire, it conducts medium and high-frequency currents without surface skin effect. Compared with other water-cooled cables of the same cross-section, it generates less heat when passing the same current;

3. Water cooled cable clamp: used to fix the outer sleeve with a clamp made of non-magnetic stainless steel with a locking device.

4. Water cooled cable end connector: also known as electrode, commonly known as cable head, using non-contact, no welding point, no welding seam manufacturing process, processed with a whole copper rod on a CNC lathe or milling machine, beautiful and durable; The connection between the electrode and the wire is made by cold extrusion, which does not damage the wire and has low resistance.

5. Minimum curvature radius of water-cooled cable: The maximum curvature radius allowed for water-cooled cables to bend under external forces.

1. Soft wire cross-sectional area: unit: mm2

2. Current carrying capacity: Unit: A Rated voltage: Unit: V

3. Cooling water flow rate: Unit: m3/h

4. Minimum bending radius: in millimeters

5. Geometric mean radius GMR: Unit: mm

6. Working water pressure: Unit: Mpa

7. Length: in meters

1. The outer sheath rubber tube of the water-cooled cable has a breakdown voltage resistance of V ≥ 4000V.

2. The outer sheath rubber hose of water-cooled cable can withstand working water pressure P ≥ 0.8Mpa.

3. There is no leakage of cooling water at the interface between the outer sheath rubber hose and the electrode.

4. The soft wire and electrode are cold pressed and fastened on the press.

5. The test tension for a nominal cross-sectional area of 200mm2 is 15KN. On this basis, for every 100mm2 increase in the nominal cross-sectional area of the water-cooled cable, the test tension value increases by 5KN.

1. The cable head (electrode) is formed by integral copper rod turning and milling according to the drawing;

2. Determine the length of copper stranded wire according to the designed length of water-cooled cable;

3. Use a dedicated wire bonding mold to press the copper stranded wire head on the 320kgf/cm2 hydraulic press of Haishan electric furnace.

4. After bundling the copper stranded wire, use a specialized copper head die on a 320kgf/cm2 hydraulic press to cold press the copper stranded wire into the cable head (electrode) to form a secure connection.

5. Use the specialized equipment of SanRui electric furnace to fit the outer sleeve onto the assembled water-cooled cable copper stranded wire and determine the size of the rubber hose to the copper end.

6. Use the specialized tool of SanRui electric furnace to fasten the clamp with locking device onto the outer sheath rubber hose.

The factory inspection of water-cooled cables shall be conducted in accordance with the following requirements. If there are any non-conforming items during inspection, they shall be repaired and retested until they are fully qualified before leaving the factory.

1. Measurement of insulation resistance of water-cooled cables: According to the provisions of 7.1.4.1 in GB/T10066.1-1988, but the measurement is carried out between the soft wire and the additional electrode, which refers to a water tank, graphite coating, wrapped metal foil or other devices or measures that form equipotential on the outer surface of the outer protective sleeve. When using a water tank as an additional electrode for measurement, the length of the water-cooled cable protruding from the water surface at both ends is 300mm.

2. Insulation and voltage withstand test of water-cooled cables: The test shall be conducted in accordance with 7.1.4.2 of GB/T10066.1-1988, but the test shall be carried out between the flexible conductor and the additional electrode, which refers to a water tank, graphite coating, wrapped metal foil or other devices or measures that form equipotential on the outer surface of the outer protective sleeve. When using a water tank as an additional electrode for measurement, the length of the water-cooled cable protruding from the water surface at both ends is 300mm.

3. Water pressure test of water-cooled cable: Place the water-cooled cable on a dedicated test bench, block the water hole of one end of the electrode, and then connect a water pipe to the other end. Apply pressure of 0.8Mpa and maintain it for 30 minutes. There should be no leakage, and the outer protective tube rubber hose should have no abnormal phenomena such as bubbling or local increase in outer diameter.

4. Tensile strength test of water-cooled cable: After the electrode is crimped with the soft wire, it is installed on the tensile machine. When the tensile machine reaches the test tension specified in Article 5 of the third item, there should be no looseness or detachment at the connection.

6. Inspection of water-cooled cable packaging: Before packaging the water-cooled cable, drain any accumulated water inside and dry it with compressed air; Clean the outer sheath hose with a nylon brush and clean it with water; Clean the electrode surface with acetone solvent. According to the size of the cable volume, packaging should be done using colored strip cloth or wooden boxes. When packaging water-cooled cables, their bending radius must not be less than the inspection certificate.

7. Transportation and storage: The equipment used for lifting and transporting large volume water-cooled cables should ensure that the water-cooled cables are not damaged. Water cooled cables should be placed straight and not suspended. It should be stored in a place free of oil stains and corrosive gases. The ambient temperature should be within the range of -10 ℃ to 55 ℃.

In the complex and precise industrial equipment system of medium frequency induction furnace, water-cooled cables play an indispensable role, but they are only one of many key components. The task undertaken by water-cooled cables is crucial and highly specialized, mainly applied to the cable connection work between intermediate frequency power supplies and induction coils.

In practical industrial production scenarios, the medium frequency induction furnace serves as the core equipment, and its various components work closely together and complement each other to ensure the stable operation and efficient production of the entire equipment. The connection position of the water-cooled cable is like the importance of the human throat for breathing, and is a key link in the entire current transmission path.

When the current is output from a stable intermediate frequency power supply, it needs to be transmitted through a specific cable, and water-cooled cables are the "bridge" that undertakes this important task. It accurately delivers the electrical energy generated by the intermediate frequency power supply to the induction coil, enabling the induction coil to generate a strong magnetic field under appropriate current, thereby realizing a series of complex industrial production processes such as heating and melting of metal materials.

In this process, water-cooled cables not only need to ensure stable transmission of current, but also need to deal with the large amount of heat generated by the current passing through. Because intermediate frequency current generates high heat during transmission, if not cooled in a timely manner, it can easily lead to high cable temperature, which can affect its performance and even cause safety accidents. The unique design of water-cooled cables enables them to effectively dissipate heat through an internal cooling water circulation system, ensuring that the cables always operate within a safe and stable temperature range, thereby guaranteeing the normal operation of the entire medium frequency induction furnace system.

Latest News

What is a Water-cooled Cable? Types and Characteristics of Water-cooled Cables

Jun. 11, 2025

Induction Furnace Water-cooled Cable

Jun. 10, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province