Jul. 17, 2025

50 Ton industrial electric arc furnace are mainly divided into two categories: alkaline electric arc furnaces and acidic electric arc furnaces.

The core difference lies in the lining materials and slag making process, which directly affect the purity and application range of steel. Let us understand its classification and characteristics together.

1. Alkaline EAF

Lining materials: masonry with alkaline refractory materials such as magnesia bricks and dolomite bricks.

Slag making process: alkaline slag materials such as lime and fluorite are used to form strong alkaline slag.

Dephosphorization and desulfurization capacity: alkaline slag can effectively absorb impurities such as phosphorus and sulfur in steel, and the dephosphorization rate can reach more than 90%, and the desulfurization rate is about 60%-80%.

Applicable steel types: high-quality carbon steel, alloy steel, stainless steel and other steel types with strict requirements on impurity content.

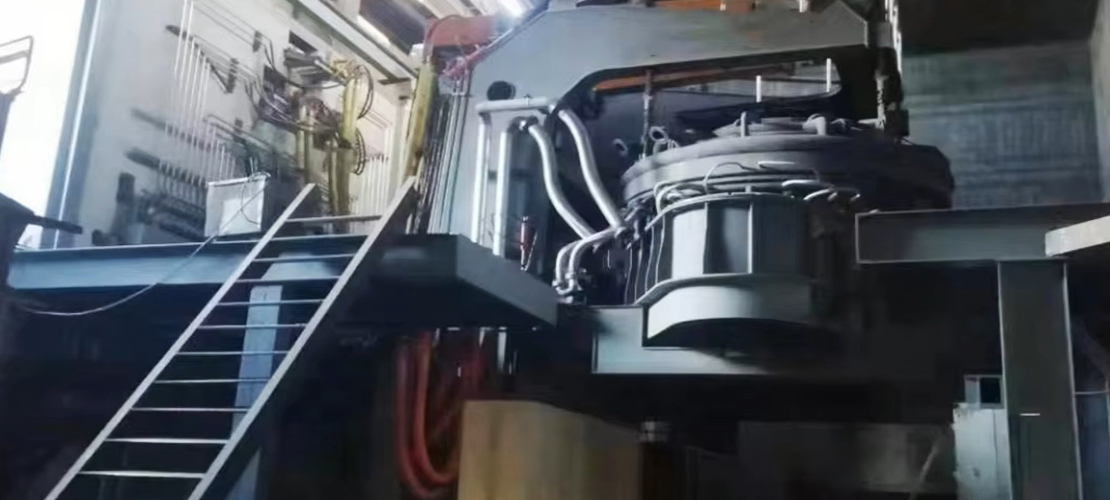

Typical case: The 50T industrial electric furnace of Shaanxi Sanrui Electric Furnace Co., Ltd. uses alkaline lining to melt carbon steel, alloy steel, stainless steel and other varieties.

2. Acidic EAF

Furnace lining material: Acidic refractory materials such as quartz sand and silica bricks are used.

Slag making process: Quartz sand and lime are used as slag materials to form acidic slag.

Dephosphorization & desulfurization ability: Acidic slag is almost impossible to dephosphorize, and its desulfurization ability is also weak, and it needs to rely on low-phosphorus and low-sulfur raw materials.

Applicable steel types: steel castings, ordinary carbon steel and other steel types with low impurity requirements.

Limitations: Due to poor dephosphorization and desulfurization ability, it is rarely used in modern steel production and is mostly used in special-shaped casting workshops.

1. Wide adaptability of raw materials, mainly scrap steel

Industrial electric furnace can directly use scrap steel as raw materials without relying on molten iron or pig iron, which is suitable for short-process production.

2. Accurate temperature control & flexible smelting

Arc zone temperature: up to 3000-6000℃, furnace temperature can reach more than 2000℃, which is much higher than smelting requirements.

3. Compact equipment structure, fast return on investment

Equipment composition: including furnace body, electrode lifting system, furnace cover lifting and rotating mechanism, hydraulic furnace tilting system, etc.

4. Energy consumption

Electricity consumption: smelting 1 ton of steel consumes about 350-600kWh of electricity, accounting for 15%-20% of the total cost.

5. High level of intelligent control

PLC intelligent regulator: control electrode lifting, furnace body tilting, furnace cover rotation and other actions to achieve automatic operation.

Special steel production: 50t electric arc furnaces is suitable for smelting high value-added steel grades such as bearing steel, tool steel, stainless steel, etc., to meet the needs of aerospace, automobile manufacturing and other fields.

Short process steelmaking: matched with continuous casting machine and rolling mill to form a short process of "electric furnace-refining-continuous casting-rolling", directly producing bars, wires or steel sections.

Regional steel mills: Sanrui 50T industrial electric furnace is suitable for the layout of small and medium-sized steel mills, flexible adjustment of production plans, and rapid response to market demand.

Latest News

Submerged Arc Furnace Ferrochrome Production

Jul. 28, 2025

Characteristics of DC Electric Furnace Equipment

Jul. 25, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province