Aug. 22, 2025

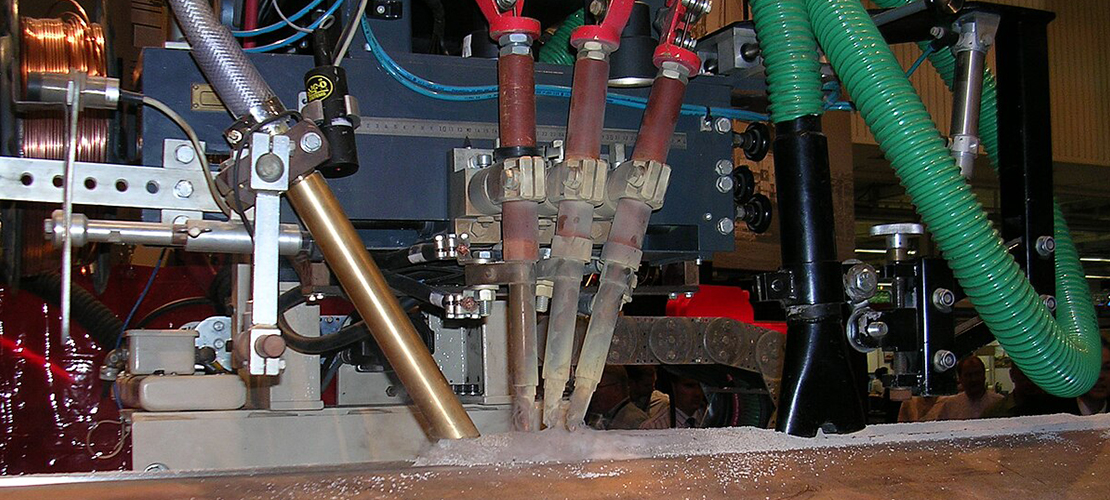

Submerged arc method (SAF) refers to a welding method performed in a submerged arc furnace in which the arc burns beneath a layer of flux.

This method is a special form of arc welding characterized by an electrode inserted into the charge, while the arc is submerged beneath a layer of flux. This prevents the welding process from being exposed to air, thus protecting the weld area.

This method is primarily used in the production of ferroalloys, using an arc and resistance to heat the ore, reducing it. Submerged arc welding uses a continuously fed wire as the metal electrode. The heat generated by the arc melts the filler metal, flux, and workpiece, forming a molten slag that shields the weld area.

SAF welding is characterized by an arc burning between the wire and workpiece under a layer of flux. The arc heat melts the wire and workpiece, forming the weld. The molten slag formed by the flux coats the weld surface, providing protection and preventing external gases and impurities from entering the weld pool, thus ensuring weld quality. Specifically, the submerged arc welding method involves the following aspects:

1. The arc burns beneath a flux layer:

Unlike conventional arc welding, the arc in submerged arc welding is covered by a layer of granular flux and is not directly exposed to air.

2. Continuously fed wire:

Submerged arc welding typically uses a continuously fed wire as filler metal, rather than electrodes as in manual arc welding.

3. Slag protection:

The flux melts during welding, forming a slag that coats the weld surface, preventing oxidation and contamination while also providing heat insulation and arc stability.

4. High productivity & quality:

Submerged arc method typically offers high welding speeds and productivity, and produces high-quality welds, making it suitable for welding thick plates and large workpieces.

5. Wide range of applications:

Submerged arc welding is suitable for welding a variety of metal materials, including mild steel, low-alloy steel, and stainless steel. It is widely used in pressure vessels, pipe section fabrication, box beams, and other fields.

Compared to other welding methods, SAF submerged arc welding offers the following advantages:

Stable weld quality: Due to the protective effect of the molten slag, the weld quality of submerged arc welding is relatively stable and less affected by the external environment.

High productivity: Submerged arc methods offers high welding speeds and high production efficiency.

Low labor intensity: Submerged arc welding is typically performed automatically or semi-automatically, resulting in relatively low labor intensity.

Submerged arc welding in submerged arc furnace typically requires the use of specialized welding equipment, such as welding machines, welding wire, and flux.

Submerged arc welding has certain requirements for the welding environment and typically must be performed indoors or under sheltered conditions.

In summary, SAF submerged arc method is an efficient, high-quality welding method with important applications in industrial production.

Latest News

3 Ton Electrode Electric Arc Furnace

Aug. 25, 2025

What is The SAF Submerged Arc Method?

Aug. 22, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province