Nov. 07, 2025

Electric arc furnaces can be divided into three categories:

Direct heating: The electric arc occurs between the electrode rods and the furnace, directly heating the furnace. This is primarily used for steelmaking, but also for ironmaking, copper production, refractory materials, and molten steel.

Indirect heating: The electric arc occurs between two electrode rods, radiating heat from the arc. This is used for smelting copper and copper alloys.

This is currently the most common and prevalent type of electric arc furnaces; the term "electric arc furnace" usually refers to this type.

Typically, three (AC furnace) or one (DC furnace) graphite electrodes are vertically inserted into the sealed furnace chamber from the top.

When energized, a strong electric arc is generated between the lower end of the electrodes and the metal charge (scrap steel, etc.), reaching temperatures exceeding 3000℃.

This arc directly contacts the charge, rapidly melting and superheating it using its extremely high heat.

High thermal efficiency: Energy is directly transferred to the furnace charge, resulting in rapid heating and high melting efficiency.

High temperature: Easily reaches the temperatures required for steelmaking (>1600℃).

Flexible control: The molten pool temperature and chemical reactions can be precisely controlled by adjusting the electrode position and current.

Large scale: Modern direct arc furnaces can have capacities of hundreds of tons, making them ideal for large-scale production.

Significant impact on the power grid: Huge current fluctuations and harmonics are generated during arc start-up and melting.

High noise: The electric arc generates significant noise.

Electrode consumption: Graphite electrodes oxidize and are consumed at high temperatures, representing a major cost factor.

The vast majority of electric arc furnace steelmaking uses direct arc furnaces. It is the core equipment in short-process steelmaking (using scrap steel as the main raw material) and, along with long-process steelmaking (blast furnace-converter) using molten iron, forms the world's two major steelmaking processes.

This is a relatively old type of electric furnace, now rarely used in large-scale steel production, but still has applications in specific fields.

Typically, two horizontally placed electrodes extend from the side of the furnace. When energized, an electric arc is generated between the tips of the two electrodes, suspended above the charge. The charge is not part of the circuit; instead, it is indirectly heated and melted through the radiant heat of the electric arc and the reflected heat from the heated furnace top and walls.

Calm Melt Pool: Without a powerful electric arc directly impacting the molten pool, there is less turbulence in the molten metal, resulting in relatively less element loss.

Suitable for Certain Alloys: Indirect heating may be more advantageous for melting easily oxidized metals (such as certain copper and aluminum alloys).

Extremely Low Thermal Efficiency: Heat must first heat the furnace space and lining before being transferred to the charge, resulting in significant energy loss and high energy consumption.

Slow Heating Rate: Due to radiative heat transfer, the melting rate is much lower than that of a direct arc furnace.

Severe Furnace Lining Damage: The electric arc directly bakes the furnace top and walls, leading to a short furnace lining life.

Small scale: Limited by heating efficiency, it's difficult to manufacture large-capacity furnaces.

Indirect EAF are currently mainly found in small foundries, used for melting non-ferrous metals (such as copper, copper alloys, aluminum alloys, etc.) or for heat preservation of cast iron.

In the steel industry, it has been replaced by more efficient medium-frequency induction furnaces.

In summary, direct electric arc furnace, due to their high efficiency, large capacity, and excellent temperature control, have become the undisputed king of modern electric arc furnaces steelmaking.

Indirect electric arc furnace, due to their inherent low efficiency, have been largely phased out in mainstream metallurgical industries, remaining only in specific niche areas.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

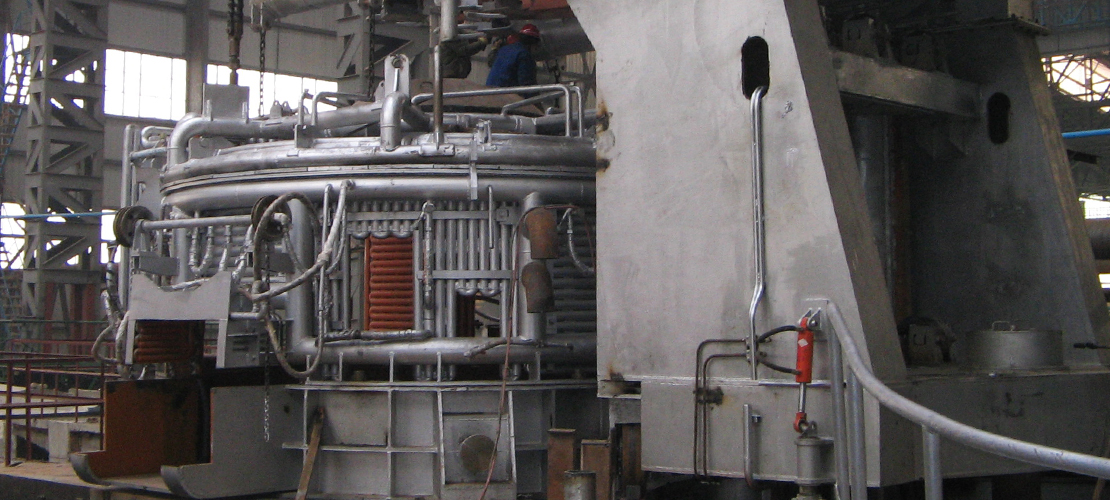

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 422, 4th Floor, Building D, No. 5, Phase I, Fengdong Free Trade Industrial Park, Xixian New District, Shaanxi Province