Nov. 06, 2025

Oxygen burner technology in electric arc furnaces is a technology that enhances the heating of the molten pool. By using other fuels to supplement electrical energy, it ensures the melting of scrap steel, shortens the smelting time of the electric arc furnace, thereby improving production efficiency and reducing smelting power consumption. Using oxygen burners to provide auxiliary energy is important for heating cold zones and improving the thermal balance within the furnace, thus achieving energy saving and efficiency improvement.

In electric arc furnace production, the main functions of using oxygen burners can be summarized as follows:

(1) Increasing the total heat in the furnace;

(2) Heating cold spots;

(3) Reducing power consumption;

(4) Shortening smelting time and increasing productivity;

(5) Shortening the time to connect to the power supply;

(6) Saving electrodes and refractory materials.

The application of oxygen in steelmaking can effectively enhance smelting, shorten smelting time, and has a good effect on reducing power consumption. One of the main experiences in energy saving—using oxygen instead of electricity—is indeed an important measure to reduce power consumption. Oxygen in electric arc furnace steelmaking is mainly used in two stages: oxygen blowing for smelting and oxygen blowing for oxidation.

To melt the solid charge as quickly as possible, it is necessary to increase the heat source and reduce heat loss to accelerate melting. During the electric arc furnace steelmaking process, oxygen blowing for smelting during the melting period is equivalent to adding a dynamic heat source in the furnace, compensating for the uneven heating caused by the three fixed electric arcs. Oxygen blowing for smelting can oxidize elements such as carbon, silicon, and manganese in the charge, releasing a large amount of heat energy and accelerating melting. Oxygen blowing for smelting can cut the charge as needed, helping to melt large pieces of refractory charge. Oxygen blowing for smelting can compensate for the disadvantage of fixed electrodes that cannot be moved, allowing the charge at the furnace wall to fall into the molten pool earlier for melting. Since oxygen blowing for smelting is a boiling exothermic reaction, it is beneficial for the early formation of slag in the initial stage, so that the degassing and dephosphorization tasks can proceed smoothly.

The following should be noted regarding oxygen blowing for smelting:

① Selection of oxygen blowing time

Oxygen blowing for smelting can only exert its true power when the charge is heated to a certain temperature. When the material near the furnace door reaches a red-hot temperature and the furnace body is tilted at a certain angle, molten steel can be seen. Oxygen can react with the red-hot charge to induce oxidation. At this point, oxygen blowing to aid melting is most effective.

② Selection of oxygen blowing pressure

The oxygen blowing pressure should not be too high. If the pressure is too high, the oxygen utilization rate will decrease, and it may also cause damage to the furnace body at the slag line. The oxygen pipe should not be too close to the charge to avoid slag splashing. The splashed molten steel will not only solidify into cold steel that is difficult to melt on the furnace walls and top, but will also affect the melting process.

Oxidation also occurs simultaneously during the melting process. Since the initial slag is formed early, it is conducive to the degassing and dephosphorization reactions. Especially for general material sources, there is no need to worry about the phosphorus content in the steel, so the power of oxygen can be fully utilized. The reactions of oxygen with carbon, silicon, and manganese are all exothermic reactions. If the molten steel has sufficient carbon content and a certain amount of manganese and silicon content, it will greatly benefit the chemical heat of the reaction with oxygen. These exothermic chemical reactions cause the molten pool to heat up rapidly, allowing us to save significant amounts of electricity used for heating.

Furthermore, the oxygen blowing operation itself provides strong agitation to the molten pool, which is beneficial for degassing and removing inclusions.

Latest News

The Difference Between Direct and Indirect Electric Arc Furnace

Nov. 07, 2025

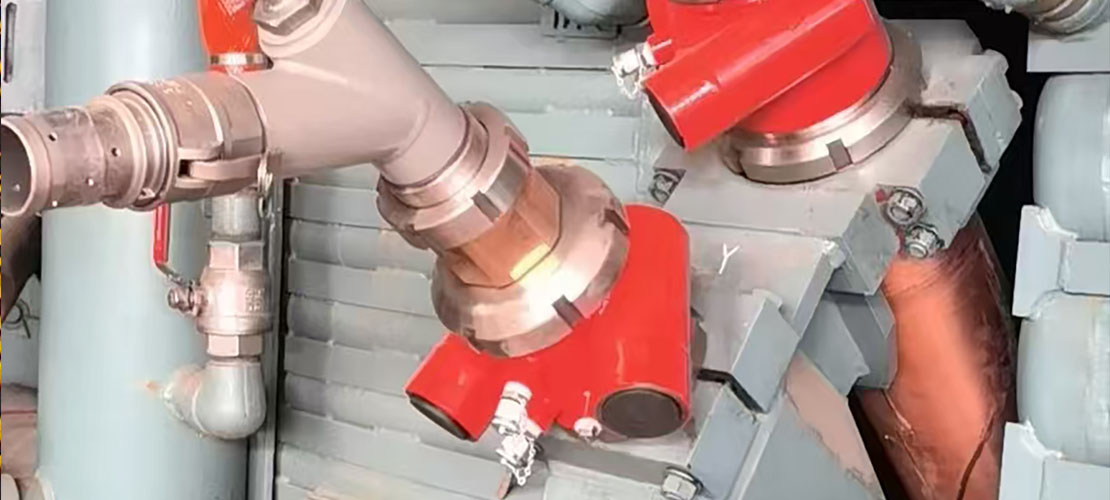

Oxygen Burner Energy-Saving Technology

Nov. 06, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 422, 4th Floor, Building D, No. 5, Phase I, Fengdong Free Trade Industrial Park, Xixian New District, Shaanxi Province