Oct. 15, 2025

Oxygen-oil burners, also known as oxygen-oil lances, are combustion devices suitable for electric furnaces that use water-cooled oxygen lances at the furnace door as the primary oxygen supply. They are primarily used to address uneven scrap melting in cold spots within the furnace and facilitate pre-blowing oxygen from the carbon-oxygen lance to assist melting and create foamed slag.

They use light diesel fuel, atomized by compressed air, and then assisted by pure oxygen. The flame temperature can reach 2500°C, and they achieve simultaneous melting of the scrap by enhancing convective heat transfer. The power of a single burner is generally 2-4 MW, with the total power accounting for 15%-30% of the transformer's rated power. The power rating per ton of steel produced is 100-200 kW/ton.

Traditional AC electric arc furnaces typically install burners in all three cold zones. They are less commonly used in DC arc furnaces due to their long arc operation characteristics. Burners are typically positioned 0.8-1.2 meters above the melt pool. Small furnaces can be mounted on the furnace door support trolley. Domestic applications include Zhujiang Steel, which has six to seven 3.5MW burners, and Anyang Steel, which uses five 3.0MW burners. During the melting phase, the furnace door preheats the scrap for 2-5 minutes. Once red-hot, oxygen blowing begins, and operation ceases once the scrap is completely melted.

Small furnaces can have burners installed on the furnace door. A single burner mounted on a support trolley allows for flexible aiming of the burner within the furnace, ensuring the flame effectively reaches the cold zone. Some oxy-oil burners are also designed to be mounted on the furnace roof, making rotation or translation of the roof inconvenient. However, for electric arc furnaces using large amounts of foamy slag, roof burners can prevent slag filling that can occur with wall burners.

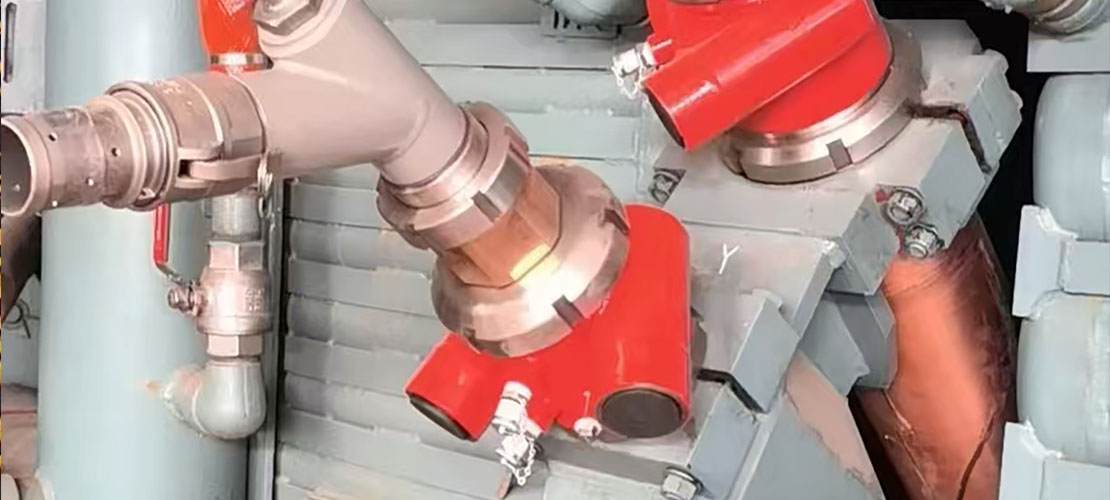

Oxy-oil burners are primarily used in areas with limited gas resources. Zhujiang Steel in China uses six to seven oxy-oil burners, each with a maximum power of 3.5MW. Anyang Steel uses five oxy-oil burners, each fueled by light diesel fuel, with a power of approximately 3.0MW. When fuel oil is combusted with industrial-pure oxygen, the maximum flame temperature can reach approximately 2500°C. Excess oxygen ensures more complete combustion. To ensure burner safety and prevent flashback, check valves are installed in the oil and oxygen supply lines. The burner utilizes a copper water-cooled structure, and quick-connect connectors connect the burner to the combustion medium line for easy replacement, maintenance, and inspection.

Convection heat transfer is the primary heat transfer method for oxy-oil burners. Ensuring thorough mixing of oxygen and fuel and rapid ignition improves flame temperature and oxygen outlet velocity, thereby increasing the surface heat transfer coefficient. However, to achieve uniform melting, the required fuel amount should be adjusted according to furnace conditions and power supply.

During the initial melting phase, the temperature difference between the flame and the scrap is greatest. At this stage, achieving a stoichiometric ratio of oxygen and fuel for complete combustion is beneficial for scrap melting and maximizes the burner's heat transfer efficiency. As the scrap temperature rises, the charge sinks and becomes compressed due to melting. The distance the high-heat gas travels through the charge decreases, reducing heat exchange efficiency and the burner's heat transfer efficiency.

At this point, the oxygen burner's heat supply should be increased. When the scrap above the charge melts, most of the heat is reflected from the melt pool surface and transferred to the exhaust gas. This causes a sudden rise in exhaust gas temperature, and fuel combustion should be reduced.

For an oxygen-oil burner, the oxygen-to-fuel ratio is approximately 2.33:1, and fuel consumption per ton of steel is ideally between 3.5 and 7 liters.

The combustion efficiency of an oxygen-oil burner depends on the scrap temperature and the heated area. Generally, oxygen-oil burners achieve the highest utilization during the melting phase. Once the scrap is completely melted, their efficiency decreases.

Therefore, the oxygen-oil ratio should be adjusted appropriately at different stages, or the burner's fuel injection should be stopped and purged with a gas medium to prevent burner clogging by slag.

The main drawbacks of oxy-oil burners are:

1. The burner structure is relatively complex.

2. The combustion medium is relatively expensive.

3. The combustion medium supply system is more complex than that of gas burners.

4. Incomplete combustion can cause carbon deposits to form on the burner nozzle, clogging the nozzle and requiring regular inspection and cleaning.

5. Carbon deposits can lead to incomplete combustion, dispersed flame power, and reduced burner power. This also places a heavy load on the dust removal system.

After the scrap is added to the furnace and power is turned on, an oxy-oil gun is first used to preheat the scrap at the furnace door for 2-5 minutes. This causes the scrap to become red-hot. The oxy-oil gun then rapidly melts the scrap at the furnace door, and then enters the furnace to blow oxygen. Once the scrap at the furnace door is mostly melted, the oxy-oil gun can be deactivated. Because the oxy-oil gun is located in the furnace door area, it is easier to control. Oxy-gas guns are also used at the furnace door. We also use the fluxing method of adding anthracite or ordinary coal to the furnace door, that is, before adding materials, we manually add bagged anthracite to the furnace door, and then put in an oxygen gun after adding materials, and the effect is also good.

Latest News

Features of The Electric Arc Furnace Dust Removal System

Oct. 14, 2025

Oct. 15, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 422, 4th Floor, Building D, No. 5, Phase I, Fengdong Free Trade Industrial Park, Xixian New District, Shaanxi Province