Dec. 24, 2025

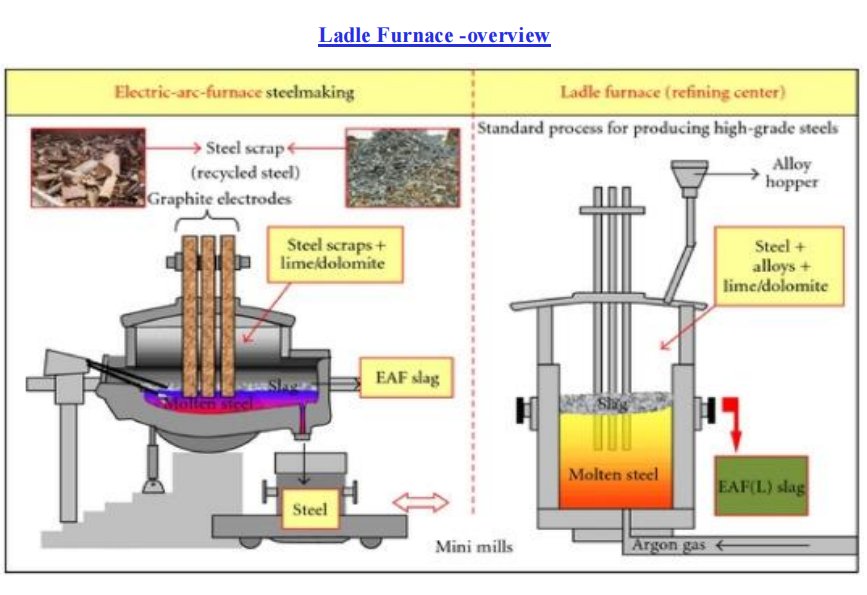

The Ladle Refining Furnace (LRF) is a secondary steelmaking unit, typically installed between the primary steelmaking furnace—such as a Basic Oxygen Furnace (BOF) or an Electric Arc Furnace (EAF)—and the continuous casting machine. Its primary function is to further refine molten steel after tapping and before casting, in order to meet the stringent requirements of high-quality steel grades with respect to chemical composition, temperature, and cleanliness.

Unlike primary steelmaking furnaces, which focus on rapid decarburization and high-volume production, the LRF emphasizes precise control and deep refining. It is therefore an indispensable process in the production of modern clean steels and alloy steels.

During transfer from the primary furnace to the caster, molten steel experiences significant heat loss. The LRF compensates for this loss through three-phase electric arc heating, maintaining the steel temperature within the required range for casting.

The main purposes include:

Compensating for heat losses during transportation and refining

Precisely controlling the final steel temperature to reduce the risk of casting interruptions

Providing suitable thermodynamic conditions for alloying and refining reactions

Stable temperature control is the foundation for accurate composition adjustment and stable casting operations.

The LRF allows precise alloying according to steel grade requirements. Commonly added alloying elements include manganese (Mn), silicon (Si), chromium (Cr), nickel (Ni), molybdenum (Mo), and vanadium (V).

At the same time, the LRF is the primary location for final deoxidation. Typical deoxidizers include aluminum (Al), ferrosilicon (FeSi), and silicomanganese alloys.

The objectives are to:

Accurately control steel composition and ensure target properties

Reduce oxygen content in molten steel and prevent oxide inclusions

Create favorable conditions for inclusion removal and steel cleanliness

The LRF is one of the key units for deep desulfurization of molten steel. Efficient sulfur removal is achieved through:

Use of high-basicity refining slag (high CaO, low FeO and MnO)

Maintenance of a strongly reducing atmosphere

Argon stirring to enhance slag–metal reactions

Typical sulfur levels after treatment can be reduced to:

Ordinary steels: ≤ 0.010%

High-quality / clean steels: ≤ 0.005% or lower

Low sulfur content significantly improves ductility, toughness, and fatigue resistance.

Dissolved gases in molten steel can seriously impair product quality:

Hydrogen (H): causes hydrogen embrittlement and flakes

Oxygen (O): leads to oxide inclusions

Nitrogen (N): causes strain aging embrittlement

In the LRF, gas content is reduced by:

Bottom argon stirring to promote gas flotation and escape

Combination with vacuum treatment (e.g., LF + VD / VOD processes) for enhanced degassing

Strengthening slag absorption of oxygen

These measures improve internal quality and service reliability of steel products.

Non-metallic inclusions are a critical factor affecting steel performance and surface quality. The LRF removes inclusions through multiple mechanisms:

Argon stirring to promote inclusion flotation

Absorption and dissolution of inclusions by refining slag

Control of deoxidation products to form removable inclusion morphologies

As a result, the content of:

Oxide inclusions

Sulfide inclusions

Complex inclusions

is significantly reduced, improving steel cleanliness, casting stability, and reducing billet defects.

Through LRF refining, molten steel achieves:

More precise chemical composition

More stable temperature

Lower gas content

Fewer inclusions

More uniform and reliable mechanical properties

Therefore, LRF is widely applied in the production of:

High-quality carbon steels

Alloy steels

Pipeline steels

Bearing steels

Tool and die steels

Automotive steels and other high-end steel grades

As steel products evolve toward higher performance, reliability, and consistency, traditional primary steelmaking furnaces alone can no longer meet the stringent requirements for composition control, cleanliness, and temperature stability. As a core secondary refining unit, the LRF is widely adopted for the following reasons.

Primary steelmaking furnaces are characterized by high productivity but limited precision in composition control. The LRF provides a stable and controllable refining environment, enabling fine adjustment of steel chemistry.

Key advantages include:

Precise alloy addition under low-oxygen, reducing conditions

Accurate control of elements such as C, Mn, Si, Cr, Ni, and Mo

Reduced alloy oxidation losses and improved alloy yield

Tight control of composition within narrow target ranges

This is especially critical for steel grades with narrow composition windows and strict performance requirements.

Residual impurities and gases in molten steel directly affect mechanical properties and service safety. The LRF enables deep purification through multiple refining measures.

Its main functions include:

Desulfurization using high-basicity slag and argon stirring

Final deoxidation to reduce oxide inclusions

Removal of dissolved hydrogen, oxygen, and nitrogen to prevent defects such as hydrogen embrittlement and strain aging

Inclusion shape control to promote flotation and slag absorption

Improved steel cleanliness is a key guarantee for producing high-strength, high-toughness, and long-life steel products.

Steel temperature is a critical factor affecting continuous casting stability and billet quality. Relying solely on tapping temperature from the primary furnace cannot compensate for heat losses during transfer and waiting.

The heating and stirring functions of the LRF allow:

Compensation for temperature drop during transportation

Precise control of final casting temperature

Temperature homogenization through argon stirring

Reduction of breakouts, clogging, and casting interruptions caused by temperature fluctuations

Stable and uniform steel temperature is essential for high-efficiency continuous casting and high yield.

Special and high-end steels impose much stricter requirements, such as:

Ultra-low sulfur, oxygen, and hydrogen levels

Narrowly controlled alloy composition ranges

Extremely high cleanliness and structural uniformity

The LRF can be flexibly combined with other secondary refining technologies (such as VD, VOD, and RH), forming a complete refining system that:

Meets the requirements of bearing steels, pipeline steels, tool steels, spring steels, stainless steels, and other specialty grades

Ensures high consistency in mechanical properties and service life

Enhances product added value and market competitiveness

The fundamental reason for adopting the LRF process is its ability to achieve higher-level composition control, steel cleanliness, and temperature stability on the basis of primary steelmaking. The LRF is not only an essential complement to modern steelmaking processes but also a critical unit for producing high-quality and specialty steels.

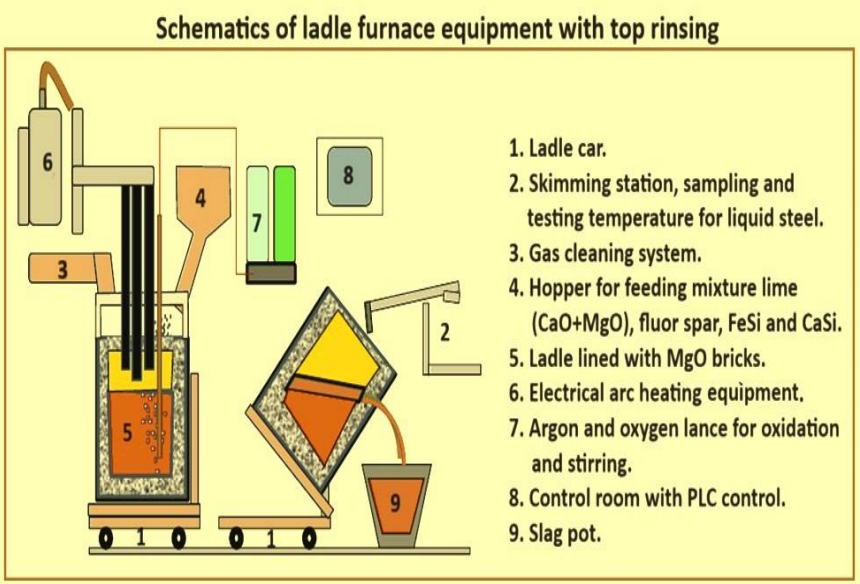

The LRF process is typically positioned between the BOF/EAF and continuous casting. Its basic steps include charging, heating, alloying and deoxidation, stirring and refining, and tapping. The main objective is precise control of steel temperature, composition, and cleanliness.

After primary steelmaking is completed in the BOF or EAF, molten steel is tapped into a ladle lined with refractory materials and transferred to the LRF station.

Key characteristics include:

Major refining reactions such as decarburization have already been completed

The ladle lining provides high temperature resistance and erosion resistance

Fluxes for slag formation may be added as required

After charging, the ladle enters the refining stage.

Once the ladle is positioned in the LRF, three-phase AC electric arc heating (sometimes supplemented by induction heating) is used to reheat and adjust the steel temperature.

The main objectives are:

Compensating for heat losses during transfer and refining

Precisely controlling the steel temperature for casting or pouring

Providing stable thermal conditions for alloying and refining reactions

Heating ensures sufficient steel fluidity throughout the refining process.

After stabilizing temperature and atmosphere, alloying and final deoxidation are carried out according to steel grade requirements.

Main operations include:

Addition of FeMn, FeSi, Al, and other alloys and deoxidizers

Precise adjustment of alloying element content

Reduction of dissolved oxygen and minimization of oxide inclusion formation

This step emphasizes accuracy and repeatability in composition control, which is essential for consistent steel properties.

Throughout the refining process, bottom argon blowing or electromagnetic stirring is used to promote molten steel circulation, ensuring uniform composition and temperature.

The main effects include:

Accelerating slag–metal reactions

Promoting desulfurization and deoxidation

Enhancing inclusion flotation and slag absorption

Improving steel cleanliness and microstructural uniformity

Stirring intensity is adjusted according to steel grade and process requirements to avoid secondary contamination.

After refining is completed and the steel temperature, chemical composition, and cleanliness meet process requirements, the steel is tapped for casting.

Typical tapping routes include:

Transfer to a tundish for continuous casting

Direct pouring into molds for ingot casting

This stage requires smooth and controlled operation to avoid secondary oxidation and temperature fluctuations, ensuring high-quality billets or ingots.

The LRF process, through heating, alloying, stirring, and refining, achieves precise composition control, stable temperature, and improved cleanliness, making it a key link between primary steelmaking and casting in modern steel production.

Latest News

Ferrosilicon Furnace's Different Reaction Temperature

Dec. 25, 2025

Ladle Refining Furnace (LRF) Process

Dec. 24, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 422, 4th Floor, Building D, No. 5, Phase I, Fengdong Free Trade Industrial Park, Xixian New District, Shaanxi Province