May. 15, 2025

The electric arc furnace refractory lining is usually composed of materials such as magnesia-chrome spinel bricks, high-alumina bricks, cold ramming paste, ramming materials and magnesia-carbon bricks, which are used to withstand the erosion of high-temperature molten steel and slag.

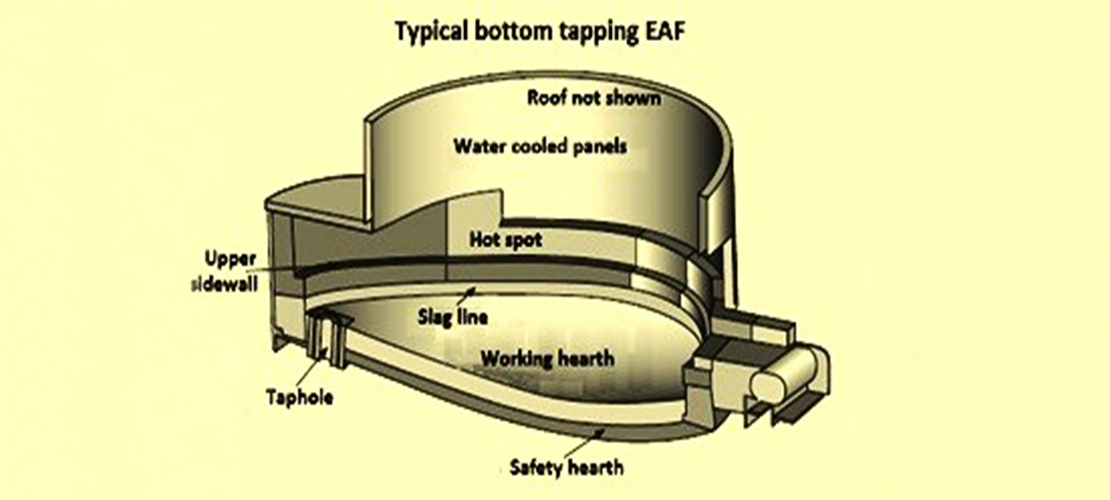

The design and material selection of the furnace lining depend on the type of electric arc furnace and the way of tapping. The side wall of the side-tapping electric arc furnace requires a lining with higher refractoriness.

At present, although there are many refractory materials, their service life is often limited, usually not more than three months. Therefore, improving materials and extending the life of the lining are important research directions in the field of refractory lining of electric arc furnaces.

The selection of refractory lining of electric arc furnaces requires comprehensive consideration of furnace type, smelting process, cost and refractory performance. The following are the key steps and points:

Temperature range:

Ordinary electric arc furnaces (1600-1800℃) can use magnesia-carbon bricks; ultra-high temperature (>1800℃) needs to consider zirconia or high-grade magnesia-calcium bricks.

Slag properties:

- Basic slag (high CaO/MgO): choose magnesia (MgO≥90%), magnesia-calcium or magnesia-carbon bricks (carbon content 10-20%).

- Acidic slag (high SiO₂): choose siliceous or alumina-silica materials (such as high alumina bricks).

- Strongly corrosive slag: magnesia-carbon bricks with added antioxidants (such as Al, Si), or magnesia-chrome bricks (pay attention to environmental protection restrictions).

Steel types to be smelted:

Stainless steel smelting requires low iron content refractory materials (such as magnesia-calcium bricks) to avoid FeO pollution.

Hot spot area of furnace wall: high temperature and severe slag corrosion, use highly corrosion-resistant magnesia-carbon bricks (such as MgO-C 14-20% carbon) or composite coatings.

Slag line area: magnesia-carbon bricks (carbon content 12-18%) or magnesia-calcium bricks that are resistant to slag penetration are preferred.

Furnace bottom and furnace slope: high mechanical strength requirements, sintered magnesia bricks or magnesia-alumina spinel bricks can be selected.

Steel outlet/electrode hole: aluminum silicon carbide bricks or prefabricated parts with high thermal conductivity and thermal shock resistance.

Refractory LiningType | Temperature Resistance (℃) | Slag Resistance | Thermal Shock Resistance | Cost | Applicable Scenarios |

Magnesia Carbon Brick (MgO-C) | 1600-1800 | High (alkaline slag) | Medium | Medium to high | Furnace wall, slag line |

Magnesia-calcium brick | 1700-1900 | Very high | Low | High | Clean steel smelting |

High alumina bricks (Al₂O₃>75%) | 1400-1600 | Medium (acidic slag) | High | Low | Low temperature area or acidic environment |

Magnesia Chrome Brick | 1700-1850 | Very high | Medium | High | Restricted (Cr⁶⁺ pollution) |

Zirconia Brick | >2000 | Very high | Low | Very high | Ultra-high temperature experimental furnace |

Low-cost solution: Use repair materials (such as magnesium gunning materials) in some parts of the furnace lining to extend the life.

Long life requirements: Use magnesium carbon bricks containing metal antioxidants (such as adding Al/Mg alloy) in hot spots, which can increase the life by 30-50%.

Avoid chromium-containing materials (such as magnesium chrome bricks), and give priority to chromium-free magnesium calcium bricks or aluminum magnesium carbon bricks.

Nano coating technology can reduce material consumption (such as MgO nano coating to improve slag resistance).

Ordinary carbon steel smelting: MgO-C bricks (14% carbon) for furnace walls and MgO-C bricks (18% carbon) for slag lines.

Stainless steel smelting: All magnesium calcium brick refractory lining to reduce iron oxide inclusions.

Conduct a small-scale hot test before trial to monitor the erosion rate (such as mm/heat).

Combine thermodynamic software (such as FactSage) to simulate the arc furnace slag-refractory reaction.

Through the above steps, you can select a targeted electric arc furnace refractory lining solution that takes into account performance, life and cost.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province