Dec. 01, 2025

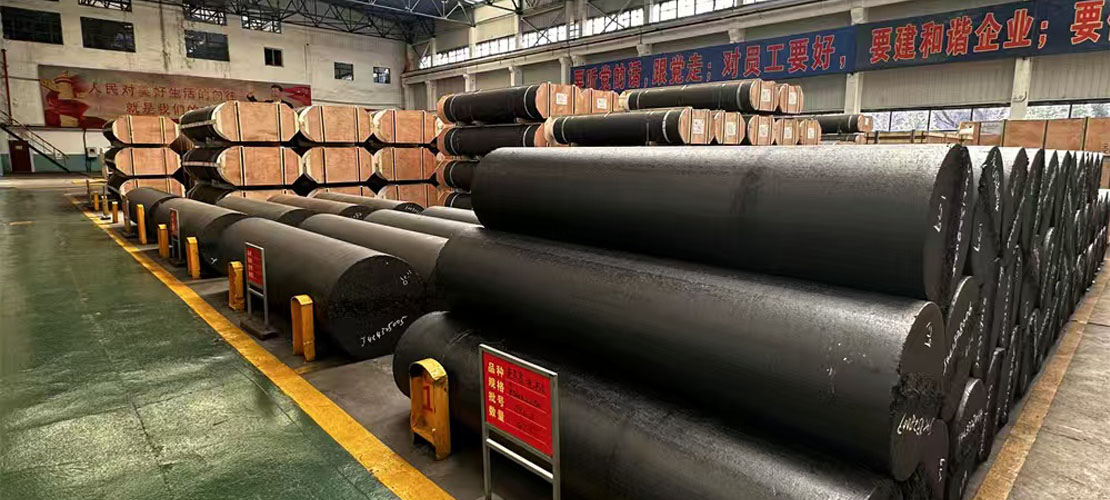

Graphite electrodes are the “core components” of electric arc furnaces. Although they may look like simple black cylinders, their manufacturing process is far more complex than it appears, making them a high-precision industrial material.

The main raw materials for electrodes are needle coke and coal pitch. Needle coke has long, fine, and well-aligned particles, which allow the electrode to withstand thousands of amperes of current without cracking, while also providing excellent electrical conductivity. Coal pitch acts like a “glue,” binding the coke particles together and transforming into a solid carbon structure when heated. In other words, needle coke serves as the skeleton, and coal pitch acts as the cement—together forming a strong and durable electrode.

The raw materials first undergo calcination, typically at temperatures between 1200 and 1400°C. Calcination removes moisture and volatile substances while increasing the density of the coke particles, laying the foundation for subsequent processing. After calcination, the coke is graded by particle size and mixed with coal pitch, then kneaded at high temperature into a uniform “coke paste.” This process is somewhat like mixing sand and cement to make mortar, but far more precise—any inconsistency can compromise the electrode’s strength and electrical performance.

The kneaded paste is then extruded into cylindrical blanks, forming the basic shape of the electrode. At this stage, the electrode is still fragile and must undergo baking, during which the coal pitch carbonizes and the structure becomes more stable. Temperature and heating rate must be strictly controlled during baking, or gases released during carbonization may cause internal cracks. To further improve density and strength, the electrodes often undergo high-pressure impregnation, where pitch is forced into internal pores, followed by a second baking cycle. For ultra-high-power electrodes, this impregnation-baking process may be repeated several times to ensure long-term stability in the furnace.

The most critical step is graphitization, where the electrodes are heated to 2800–3000°C. During this process, carbon atoms rearrange to form a hexagonal graphite structure, dramatically reducing electrical resistance while improving conductivity and thermal stability. One way to visualize this is imagining loosely packed charcoal being transformed into a solid, heat-conductive “high-tech carbon rod.”

After graphitization, the electrodes undergo precision machining, including turning, threading, and connector shaping, to ensure dimensional accuracy and proper contact performance. Finally, every electrode is rigorously tested for electrical resistivity, density, flexural strength, and thermal expansion to guarantee stable performance under high temperatures and high currents.

In summary, the production of a graphite electrode is a sophisticated integration of materials science, thermal engineering, and mechanical processing. From raw material selection, calcination, kneading, baking, and impregnation to graphitization, machining, and testing, every step is crucial. This complex manufacturing process ensures that graphite electrodes are not only strong and durable but also capable of withstanding the extreme conditions inside an electric arc furnace, which explains their essential role in steelmaking.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 422, 4th Floor, Building D, No. 5, Phase I, Fengdong Free Trade Industrial Park, Xixian New District, Shaanxi Province