Jan. 04, 2026

Ferroalloy electric furnaces are the most critical production equipment in ferroalloy smelting. According to their technological functions, they can be classified into reduction electric furnaces and refining electric furnaces.

The reduction electric furnace, also known as a submerged arc furnace (SAF) or ore-thermal furnace, operates by inserting electrodes deep into the furnace charge, where submerged arc heating and reduction reactions take place. Depending on structural design and operating mode, reduction electric furnaces can be classified as open-type, semi-closed, or closed, with furnace bodies designed as fixed or rotating types.

With increasingly stringent environmental regulations and advances in waste heat recovery technology, closed furnaces or low-fume hood systems have been gradually adopted in modern ferroalloy production. In semi-closed furnaces, rotation of the furnace body effectively eliminates hanging materials, reduces “blow-through” or “flare” phenomena caused by burden accretion, improves burden distribution uniformity, and enlarges the reaction zone, thereby promoting stable furnace operation and smooth burden descent.

The capacity of ferroalloy electric furnaces is usually expressed by the rated capacity of the furnace transformer, measured in kilovolt-amperes (kVA).

Before the 1950s, furnace capacities generally ranged from several hundred to slightly over 10,000 kVA. Thereafter, furnace capacity increased progressively. By the 1970s, newly constructed furnaces typically had capacities of 20,000–40,000 kVA. The largest closed furnace reached a capacity of 75,000 kVA, while the largest semi-closed furnace achieved up to 96,000 kVA.

Modern reduction electric furnaces generally adopt a cylindrical furnace body equipped with three electrodes, whereas large-scale ferromanganese furnaces commonly employ a rectangular multi-electrode configuration. Some large ferrosilicon furnaces are fitted with furnace rotation mechanisms, allowing the furnace body to rotate horizontally or oscillate back and forth, typically completing a full 360° rotation over a period of 30 to 180 hours.

Closed furnaces are equipped with sealed furnace covers, while semi-closed furnaces are provided with adjustable operating doors beneath the hood to control air intake and flue gas temperature.

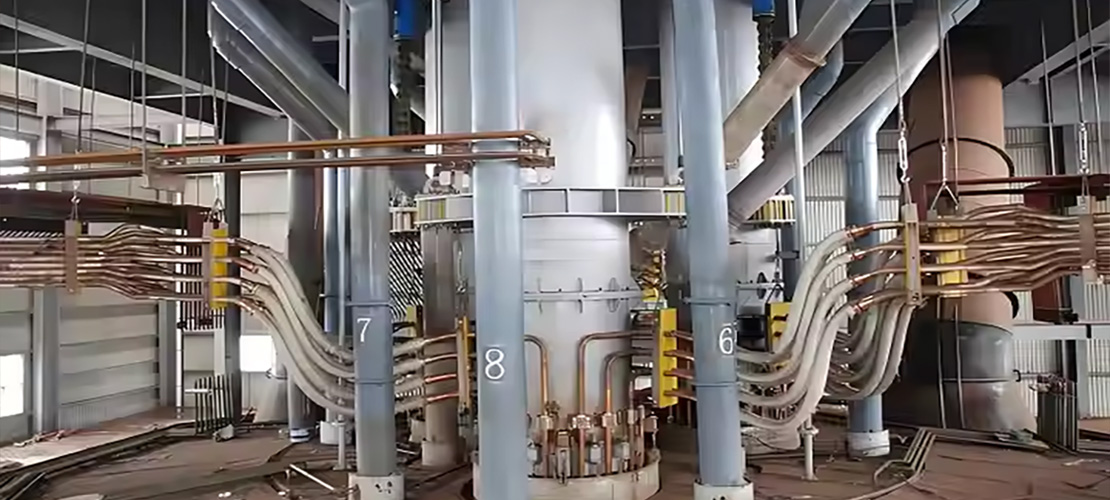

Reduction electric furnaces widely employ continuous self-baking electrodes, with maximum diameters reaching up to 2000 mm, some of which are of hollow design. A continuous self-baking electrode consists of a thin steel shell and electrode paste. During operation, the electrode paste is gradually baked and solidified by the heat generated from electric current and thermal radiation from the furnace. As the electrode is consumed, the electrode shell is welded section by section and replenished continuously with electrode paste.

The electrode holding system comprises conductive copper contact shoes, copper tubes, and clamping rings. Its primary functions are to transmit electric current, secure the electrode at a specified height, and regulate the baking condition of the electrode paste. The electrode lifting and pressure-release mechanisms are used to adjust the electrode penetration depth into the furnace charge.

The electrical circuit connecting the low-voltage side of the transformer to the electrode holders is known as the short network. It is characterized by large cross-sectional conductors designed to carry extremely high currents. In large electric furnaces, the secondary windings of the transformer are typically connected in a delta configuration at the electrodes through the short network. The short network mainly consists of rigid busbars, flexible busbars, and copper pipes.

Refining electric furnaces are primarily used for the production of medium-carbon, low-carbon, and micro-carbon ferroalloys. Their capacity generally ranges from 1500 to 6000 kVA, and their structural forms include open fixed furnaces and tilting furnaces with covers.

Open fixed refining furnaces are structurally similar to reduction electric furnaces and may also be equipped with continuous self-baking electrodes. In contrast, tilting refining furnaces resemble electric arc steelmaking furnaces and typically use graphite electrodes or carbon electrodes for heating and refining operations.

Latest News

What is Desulphurisation in Ladle Furnace?

Jan. 05, 2026

Classification and Characteristics of Ferroalloy Electric Furnaces

Jan. 04, 2026

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 422, 4th Floor, Building D, No. 5, Phase I, Fengdong Free Trade Industrial Park, Xixian New District, Shaanxi Province