Jan. 13, 2026

In submerged arc furnace systems, apparent power is usually used to represent the capacity of the equipment. In fact, it refers to the rated capacity of the transformer.

Active power is the power that actually converts electrical energy into heat and other forms of useful energy. It reflects the effective working capability of the electric furnace.

Reactive power is the power used to establish electromagnetic fields (such as in capacitors and inductors). It is periodically exchanged between the load and the power source. Although it is not directly consumed, it is indispensable for maintaining the normal operation of the transformer.

Generally, the power factor of a submerged arc furnace before low-voltage reactive power compensation is called the natural power factor. The natural power factor of large submerged arc furnaces is usually low, in the range of 0.6–0.7 (except for ferronickel furnaces).

S — Apparent power, kVA

P — Active power, kW

Q — Reactive power, kVar

Cosφ — Power factor

( S^2 = P^2 + Q^2 )

( \cosφ = P / S )

( P = S × \cosφ )

( Q = S × \sinφ )

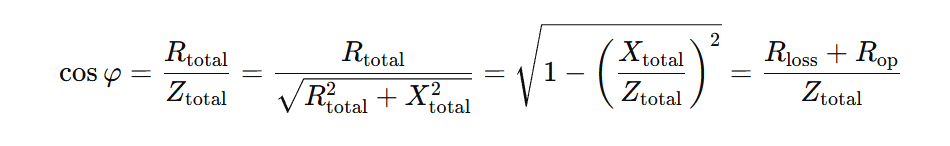

R_total — Total resistance of the power supply circuit, including transformer, short network (furnace bus bar), furnace burden, and arc resistance

Z_total — Total impedance of the power supply circuit

X_total — Total reactance of the power supply circuit

From the formula: ( Z = R + jX ), therefore ( Z^2 = R^2 + X^2 ) (impedance triangle)

R_operation — Operating resistance, generally defined as the ratio of electrode voltage to electrode current

R_loss — Total resistance of power supply equipment, including transformer and furnace bus bar.

From the various power factor formulas, it can be seen that reducing equipment impedance and increasing operating resistance can both improve the power factor.

However, reducing equipment impedance can only be achieved during the design stage. Once the system is built, the impedance of the transformer and short network is fixed and difficult to change.

Operating resistance, on the other hand, can be adjusted during furnace operation according to burden conditions and operating practices.

Therefore, improving power factor must be approached in two stages: design & construction, and production & operation. Omitting either stage will prevent achieving the desired result.

The submerged arc furnace should be reasonably designed so that electrode diameter, furnace inner diameter, electrode pitch circle diameter, and other dimensions match the selected furnace transformer.

If the transformer must operate under overload to meet the active power demand of the furnace, both the furnace and transformer will consume large amounts of reactive power, resulting in a very low power factor.

Proper selection of raw materials and control of particle size and moisture content, while maintaining stable burden conditions, can reduce reactive power fluctuations caused by load variations.

Precise adjustment of electrode position and penetration depth helps stabilize the arc and reduce reactive power generation.

It is recommended to introduce an automatic control system for submerged arc furnaces to implement optimal operating modes through intelligent control, thereby improving power factor.

Nowadays, large submerged arc furnaces are generally equipped with low-voltage reactive power compensation systems (SVC).

If you'd like, I can also provide a technical-style translation suitable for academic papers or a simplified version for training materials.

Latest News

Jan. 15, 2026

Calculation and Improvement Methods of Power Factor for Large Submerged Arc Furnaces

Jan. 13, 2026

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 422, 4th Floor, Building D, No. 5, Phase I, Fengdong Free Trade Industrial Park, Xixian New District, Shaanxi Province