Dec. 11, 2025

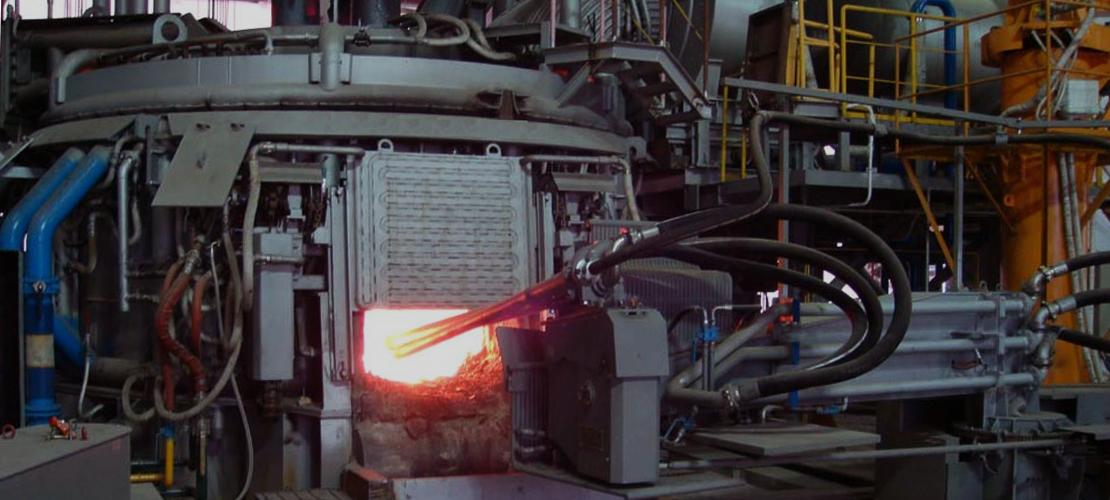

The 5 ton small electric arc furnace is a classic small-to-medium-sized furnace type in the modern steel industry, renowned for its flexibility, relatively low investment threshold, and rapid production response. It can serve as a core piece of equipment in a small, independent steel plant, or as auxiliary smelting equipment in large steel enterprises producing special steels or alloys.

The core function of an electric arc melting furnace is to melt solid metal raw materials (scrap steel, pig iron, alloys, etc.) through a high-temperature electric arc generated by graphite electrodes, and then refine them to obtain molten steel of a specific composition and quality. Therefore, its smelting range mainly depends on the charge composition and subsequent refining processes.

This is the most common and economical application of a 5-ton EAF, primarily targeting the building materials and general structural components markets.

Steel grades:

Q235 (A36), Q345 (16Mn), 20, 45 steel, etc.

Raw Materials:

Primarily scrap steel (80%-95%), with a small amount of pig iron or direct reduced iron added to adjust carbon content and dilute residual elements (such as copper and tin) in the scrap steel.

Characteristics (Traditional "Old Three-Stage" or Modern High-Efficiency Smelting):

Charging: Scrap steel and pig iron are loaded into the electric furnaces using baskets.

Melting Stage: The electrodes descend to ignite the arc, melting all the furnace charge. This stage consumes the most electricity, approximately 60-70% of the total.

Oxidation Stage: After the molten steel is cleared, oxygen is blown in and ore (iron oxide) is added. CO bubbles are generated through the carbon-oxygen reaction, achieving decarburization, dephosphorization, and removal of gases (H, N) and inclusions. This is a crucial step in quality control.

Reduction Stage: Oxide slag is removed, lime and fluorite are added to create new slag, and ferrosilicon, ferromanganese, aluminum, etc., are added for deoxidation, desulfurization, and fine-tuning of alloy composition.

Modern processes have largely replaced this with "deoxidation and alloying during steel tapping."

Tapping: After the molten steel reaches the required composition and temperature, it is tapped from the furnace to the ladle for ladle refining (if applicable) or direct casting.

The flexibility and controllability of the 5-ton electric arc melting furnace are ideal for small-batch, multi-variety production of special steels, which is its key advantage.

Steel Grades:

Gear steel (e.g., 20CrMnTi), bearing steel (e.g., GCr15), spring steel (e.g., 60Si2Mn), quenched and tempered steel (e.g., 42CrMo), etc.

Raw Materials:

High-quality scrap steel (e.g., recycled material for this steel grade) and pig iron are selected, with strict control over residual elements. Alloying elements (Cr, Ni, Mo, V, etc.) are added in ferroalloy form.

Features:

Stricter raw material control: Uses pure scrap steel or direct reduced iron to reduce harmful residual elements.

More precise oxidation period operation: Deep dephosphorization to prevent the loss of alloying elements through oxidation.

More complex reduction/alloying processes: These require precise calculations and batch addition of precious alloys to ensure uniform composition and minimal burn-off.

They typically require ladle refining: such as being used in conjunction with an LF furnace (ladle refining furnace). The electric arc furnace is primarily responsible for efficient melting, while desulfurization, deep deoxidation, precise composition fine-tuning, and temperature adjustment take place in the LF furnace. This is the standard configuration for producing high-quality alloy steel.

These steels have extremely high requirements for purity, microstructure uniformity, and carbide distribution. A 5-ton electric furnaces is ideal for small-scale, refined production.

Steel Grades:

High-speed steel (e.g., W6Mo5Cr4V2), hot-work die steel (e.g., H13), cold-work die steel (e.g., Cr12MoV), etc.

Raw Materials:

Mostly smelted using a return process, which utilizes large amounts of scrap of the same steel grade, combined with pure iron and alloys. Sometimes a "single slag method" is also used to reduce oxidation loss.

Characteristics:

High proportion of returned materials: Reduces costs and utilizes alloying elements in the scrap. Extremely strict control over the oxidation period is required to prevent over-oxidation of high-value elements such as tungsten, molybdenum, and chromium.

Advanced ladle refining is essential: in addition to the LF furnace, VD (vacuum degassing) or VOD (vacuum oxygen decarburization) equipment may be needed to further reduce gas and inclusion content. A 5-ton EAF is often used as the primary refining furnace in these refining lines.

There is an inherent contradiction between the requirements for decarburization and chromium retention in stainless steel smelting, as ordinary electric arc melting furnace have a very narrow operating window.

Smelting stainless steel alone in a 5 ton small electric arc furnace is economically unfeasible and difficult to control in terms of quality, but it is reasonable as a primary refining furnace.

Process:

First step:

Melt the raw materials (scrap stainless steel, ferrochrome, nickel, etc.) in 5-ton electric furnaces for preliminary dephosphorization and alloying to obtain a high-carbon, high-chromium mother liquor.

Second step:

Transfer the molten steel to an AOD (argon-oxygen decarburization furnace) or VOD furnace. In these devices, deep decarburization is achieved under low temperature, high vacuum, or inert gas dilution conditions by blowing in a mixture of inert gas and oxygen, while minimizing chromium oxidation. This is the core refining step in stainless steel production.

Many foundries (especially precision casting and alloy steel foundries) are equipped with 5-10 ton electric arc furnaces for smelting their own molten steel.

Characteristics:

The process is similar to the alloy steel production described above, but the tapping temperature is required to compensate for the temperature drop during casting. Control of the composition directly affects the final performance of the castings.

Applications:

Directly cast into various steel castings, such as power plant valves, marine crankshafts, wear-resistant liners, heat-resistant components, etc.

By changing the EAF furnace lining material (e.g., using magnesia or neutral lining) and adjusting the electrical system, a 5t electric furnace can theoretically be used to smelt copper and copper alloys, nickel alloys, etc. However, this is not its primary design function; its efficiency and economy are generally inferior to induction furnaces, and it is only used in certain specific scenarios (such as processing special materials using existing equipment).

A 5 ton small electric arc furnace is far more than just a device for "melting steel." By combining different raw material combinations, internal refining processes, and crucial external refining equipment, it can become a powerful micro-steel platform, producing a wide range of products from ordinary building materials to high-end tool and die steels. It is an indispensable metal smelting furnace in the special steel industry chain.

What it can specifically produce depends largely on the raw material supply chain, process technology, and downstream refining capabilities configured for it by the enterprise.

Latest News

Refractory For Smelting Ferrosilicon Furnace

Dec. 15, 2025

5 Ton Small Electric Arc Furnace for Sale

Dec. 11, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 422, 4th Floor, Building D, No. 5, Phase I, Fengdong Free Trade Industrial Park, Xixian New District, Shaanxi Province