Sep. 19, 2025

30 ton electric arc furnace are commonly used to smelt a variety of metals, most commonly melting scrap steel to make steel. They are also used to smelt other metals, such as specialty steels and non-ferrous metals like copper and aluminum.

The steelmaking electric furnace process allows for precise control of temperature and composition, enabling the production of various grades of steel, making it widely used in industrial production.

EAF smelting furnaces are used for short-cycle steelmaking, using 100% scrap steel, scrap steel + molten iron (pig iron), or scrap steel + sponge iron (DRI) as raw materials.

Raw Material Requirements: Primarily scrap steel, clean and free of rust, oil, and non-ferrous metal impurities. Scrap steel should be stored separately according to its composition, and sulfur and phosphorus content should be minimal.

Charging Strategy: Charge steel in batches from a top hopper, adhering to the principle of "dense at the bottom, loose at the top" to optimize the charge distribution to accelerate melting and minimize electrode wear.

Core Objective: Rapidly melt the solid charge into a uniform molten steel and perform preliminary dephosphorization.

Key Operations: Use medium voltage during the arc starting phase to avoid damaging the furnace lining; use maximum power during the borehole drilling phase to rapidly melt the charge; and accelerate the reaction by blowing oxygen.

Process Control: Add lime and ore to the steelmaking electric furnace to create slag, promoting dephosphorization and reducing metal volatilization.

Key Tasks: Decarburization and dephosphorization, removal of gases and inclusions, and raising the molten steel temperature.

Key Operational Points: Add ore or oxygen to stimulate boiling in the molten pool, forming a highly oxidizing slag; control the decarburization rate and temperature to ensure sufficient floating of impurities.

Endpoint Determination: When the molten steel's carbon content, phosphorus content, and temperature meet the specified standards, remove the oxidized slag and enter the reduction phase.

Core Function: Create reducing slag for deoxidation and desulfurization, adjust the chemical composition, and control the temperature.

Key Steps: Pre-deoxidation is performed by adding ferromanganese, followed by lime, fluorspar, and carbon powder to create a thin slag; alloying elements such as ferrosilicon and ferrochromium are added in batches to adjust the composition.

Final Deoxidation: Aluminum is inserted for final deoxidation to ensure the purity of the molten steel.

Tapping Conditions: Molten steel melted in a 30 ton electric arc furnace must meet acceptable composition, be well deoxidized, and meet temperature requirements.

Post-Processing: After pouring the molten steel into a ladle, it can be continuously cast or molded. Some processes incorporate an LF furnace for off-furnace refining.

Vacuum Consumable Arc Furnace: For specialty alloy production, melting is performed under vacuum to eliminate porosity and inclusions. It is suitable for high-end materials such as titanium alloys and high-temperature alloys.

Process Type Selection: Depending on the steel grade required, oxidation, return oxidation, or non-oxidation methods can be selected. The oxidation method is suitable for most steel grades; the return oxidation method is used for steels with high alloying elements, such as stainless steel; and the non-oxidation method has strict raw material requirements but lowers energy consumption.

In summary, the specific process of steelmaking electric furnace must be designed based on equipment configuration, raw material conditions, and product positioning.

When using an EAF smelting furnaces, its recommended to further refer to the equipment manual or industry specifications.

Latest News

Electric Arc Furnace Smelting - Batching and Feeding

Sep. 22, 2025

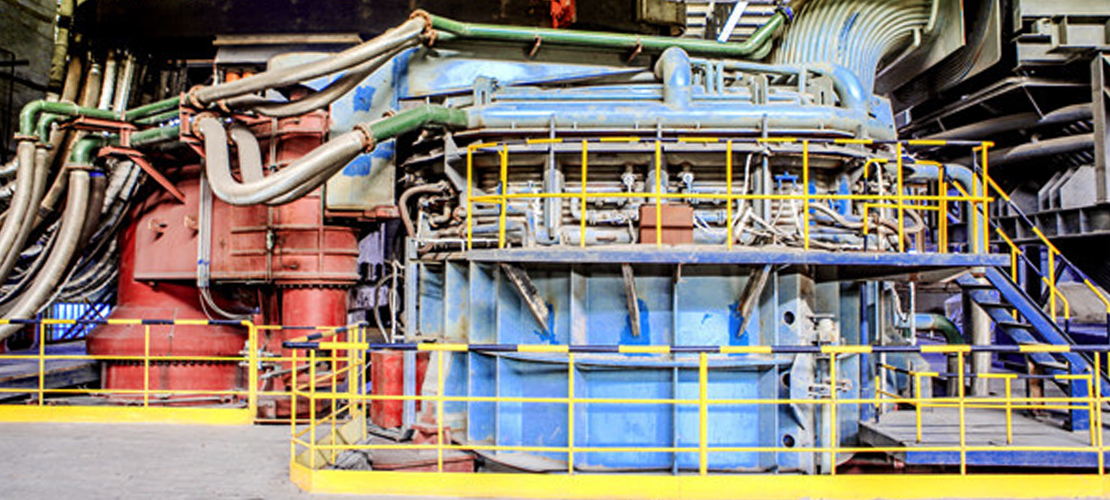

30 Ton Electric Arc Furnace Smelting Equipment

Sep. 19, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province