Sep. 24, 2025

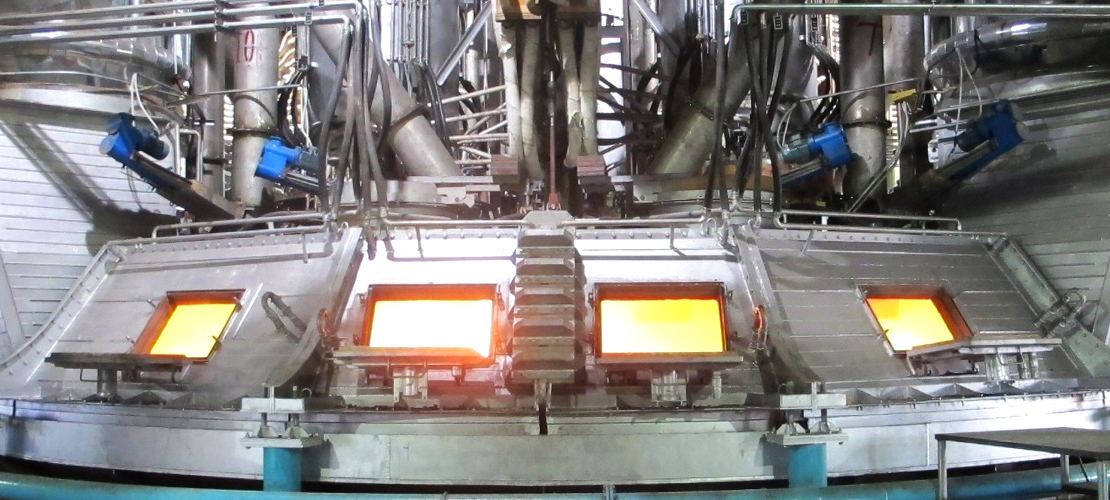

Submerged arc furnace require high temperatures for efficient metal extraction and reduction reactions. These extreme temperatures ensure the effective chemical reactions required for metal smelting, resulting in highly efficient production.

SAF submerged arc furnaces temperature typically range from 1350°C to 2000°C, depending on the type and application. For example, ferroalloy furnaces range from 1600°C to 1750°C, while calcium carbide furnaces reach temperatures as high as 1900°C to 2000°C to meet the requirements of metal extraction and reduction reactions.

SAF generally refer to high-temperature smelting furnaces, such as leaching furnaces, rotary kilns, and flat-top furnaces in pyrometallurgy. They are also sometimes referred to as submerged arc furnaces. They are widely used in the smelting and refining of the following metals:

High-temperature treatment in iron and steel smelting and alloying processes;

Copper extraction, blister copper smelting, and the smelting process in copper production;

Bauxite pretreatment, alumina reduction furnace processes, and high-temperature treatment of aluminum alloys. High-temperature treatment during the smelting and purification of nickel, chromium, and their alloys.

Non-ferrous metals such as lead, zinc, silver, and gold. For example, the separation and purification of multi-metal systems during high-temperature smelting.

Metals such as manganese, tungsten, and molybdenum. Smelting and purification under specific process conditions.

Extraction of precious and rare metals.

Silicon-chromium furnaces: Temperature range 1600-1750°C.

Silicon-manganese furnaces: Temperature range 1350-1400°C.

Calcium carbide furnaces: Temperature range 1900-2000°C.

Ferroalloy furnaces: Operating above 1600°C.

The specific conditions vary depending on the SAF furnace type, process, raw materials, and equipment, but most submerged arc furnace affected by the following factors.

1) Raw material properties

2) Coal gas/combustion system

3) Reaction thermodynamics and kinetics

4) Furnace design and thermal parameters

5) Energy management and operating procedures

6) Operation and maintenance factors

7) Safety and environmental constraints

If you would like, please provide the following information so we can provide a more detailed analysis and recommendations:

The type of submerged arc furnaces (e.g., direct steelmaking furnace, copper smelting furnace, magnesium aluminothermic furnace, etc.) and process flowsheet you require.

The target metal or product.

The main composition and particle size distribution of the raw material, as well as the type and dosage range of the carbon source.

Daily and annual production capacity, etc.

For any inquiries or questions regarding SAF, EAF, LRF, IF, VD, VOD, and other smelting equipment, please feel free to contact Sanrui Electric Furnace. We provide one-stop service and turnkey projects.

Latest News

In Which Industries Are VOD Furnaces Most Widely Used?

Sep. 29, 2025

What is The Temperature of a Submerged Arc Furnace?

Sep. 24, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province