Jul. 09, 2025

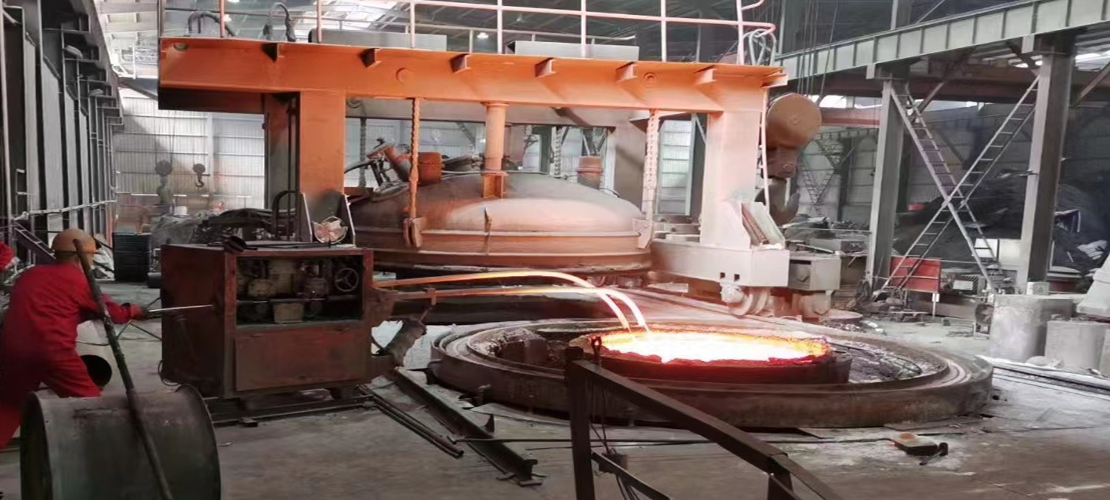

Both VD furnace and VOD furnace are refining furnaces.

VD furnace is a vacuum refining furnaces, which is mainly used to remove gas impurities such as hydrogen and nitrogen in steel. VOD furnaces is developed on the basis of VD furnaces. It is equipped with oxygen gun on the vacuum cover of VD furnace, which enables it to carry out more refined smelting, such as stainless steel production.

In other words, VOD furnace is an improvement of VD furnace, adding the function of oxygen blowing, which can better control the composition of steel, realize decarburization, dephosphorization and other operations, and further improve the quality of steel. Therefore, VOD refining furnace adds smelting function on the basis of VD refining furnace, which is more suitable for the production of specific steel grades.

VD vacuum furnace is a widely used refining furnace. It is a method of vacuum treatment of molten steel by placing the primary molten steel of electric furnace and converter in a closed tank and vacuumizing it, and blowing argon at the bottom of the ladle for stirring. After melting and preliminary blowing in electric furnace and converter, it is placed in vacuum tank (vacuum chamber) through bottom blowing argon stirring and vacuum degassing process to obtain pure molten steel. It can effectively reduce the hydrogen and nitrogen content in steel, remove oxygen in steel through carbon-oxygen reaction, and remove sulfur in steel through the full reaction of alkaline slag and molten steel.

The principle of VD furnaces are use a five-stage steam jet pump to make the vacuum chamber work below 67Pa, and achieve the purpose of refining through the effect of negative pressure. The normal working time of VD furnaces is 30 minutes.

Compared with VD vacuum furnace, VOD vacuum furnace has very high requirements on the quality of refractory materials. VOD furnace is often combined with electric furnace or converter, and the process flow usually adopts double connection method. The normal working time of VOD furnace is about 1 hour.

VD furnace is generally matched with LF furnace, and the composition and temperature adjustment are completed by LF furnace, and degassing and stirring are completed by VD furnace. There is also an oxygen gun installed on the vacuum cover of VD furnace to smelt stainless steel, which is called VOD furnace.

VD is mainly used for bearing steel deoxidation;

VOD is mainly used for stainless steel smelting.

VD ladle refining furnace can vacuum degas molten steel, fine-tune alloy composition under vacuum and stir with argon.

VOD ladle refining furnace is oxygen blowing, decarburization, vacuum degassing, and fine-tune alloy composition under vacuum. It is mainly used for refining ultra-low carbon stainless steel and electrical pure iron.

VD furnace and VOD furnace can adopt single station or double station. The vacuum tank is arranged in elevated or pit type, or vehicle-mounted. The movement of vacuum tank cover can be swing-open or vehicle-mounted.

VD/VOD vacuum refining furnace consists of vacuum tank, vacuum tank cover and tank cover lifting mechanism, ladle, oxygen gun mechanism, vacuum feeding device, temperature measurement sampling and observation system, oxygen system, argon system, cooling water system, vacuum pump system, etc.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province