Aug. 08, 2025

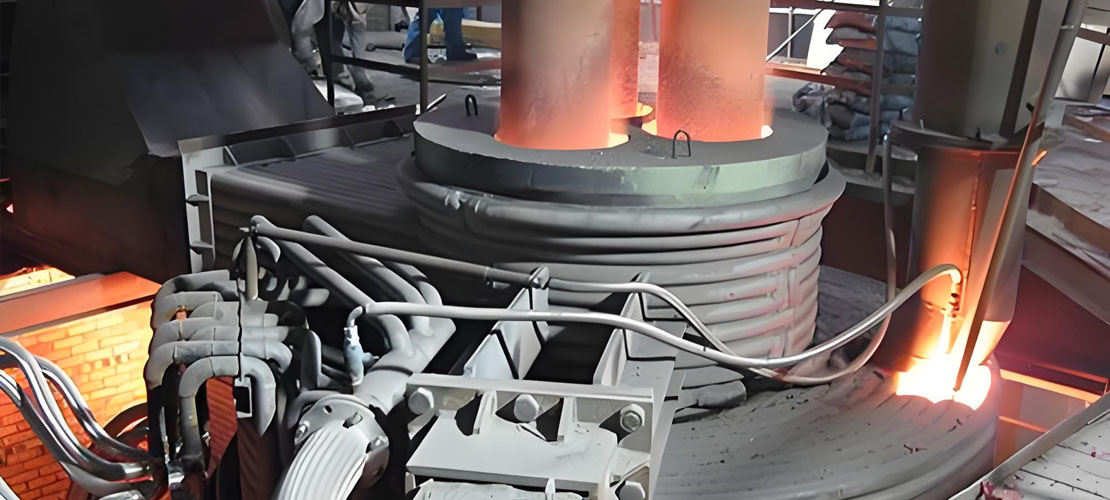

The refining furnace regulator/electrode regulator (Fer) adopts a stable electrode admittance control strategic planning. This is achieved through fast and accurate calculation of instantaneous active and reactive power using algorithms such as instantaneous d-QVAR and FFT. The regulator adopts this strategy to control the real-time three-phase admittance of the furnace, balance the three-phase power of the furnace, reduce the impact and shock on the connected power grid, and then proceed with the calculation of power output. The regulator adopts this strategy to control the real-time three-phase admittance of the furnace, balance the three-phase power of the furnace, reduce the impact and shock on the connected power grid, and then advance the production rate, save energy, and reduce electrode consumption.

Refining furnace regulator/electrode regulator (FER) is not only designed to end stable electrode adjustment; And it is also planned to integrate with the furnace reactive power compensation system (RXPESVSCS) through high-speed optical communication interface, and then form a more intelligent electrode adjustment, more efficient melting process, and better reactive power compensation effect. This helps to advance the smelting power and further reduce the impact on the power grid.

(1) The control of furnace electrodes becomes smoother, and the impact on the power grid is smaller when melting together. The RXPE electric arc furnace electrode regulator (FER) was planned using a high-speed processor (DSP/FPGA) instead of the traditional planning of a programmable logic controller (PLC). Then, the electrode regulator was planned using a high-speed processor (DSP/FPGA) instead of the traditional planning of a programmable logic controller, and the calculation speed and care time of the electrode regulator were advanced.

In addition, an instantaneous reactive power control strategy was chosen instead of the traditional cycle level accounting strategy based on power frequency. By using this software to manipulate innovation, the calculation speed and care time of the melt can be improved. In addition, an instantaneous reactive power control strategy was chosen instead of the traditional cycle level accounting strategy based on power frequency. By using this software to manipulate innovation, during the drilling and melting stages of the furnace, when raw material collapse occurs, assuming that the electrode comes into contact with the raw material or is immersed in a liquid pool, the electrode can lift much faster than in earlier years. In this way, the electrode of the electric arc furnace can be used in both the drilling and melting stages. When raw material collapse occurs, assuming that the electrode comes into contact with the raw material or is immersed in a liquid pool, the electrode can be lifted much faster than in earlier years. In this way, the electrodes of the electric arc furnace can be more flexible for care; The arc voltage and arc current become more stable; The impact on the power grid during smelting becomes much smaller, and the severity of three-phase imbalance and flicker will be significantly suppressed. Provide more active care; The arc voltage and arc current become more stable; The impact on the power grid during smelting becomes much smaller, and the severity of three-phase imbalance and flicker will be significantly suppressed.

Refining furnace regulator/electrode regulator (FER) is not only designed to achieve stable electrode regulation; And it is also planned to integrate with the furnace reactive power compensation system (RXPESVSCS) through high-speed optical communication interface, and then form a more intelligent electrode adjustment, more efficient melting process, and better reactive power compensation effect. This helps to advance the smelting power and further reduce the impact on the power grid.

(2) The refining furnace smelting can move forward. With the RXPE electric arc furnace electrode regulator (FER), the melting operation of the electric arc furnace will be more stable during the same operation process. The situation of arc extinguishing will be significantly reduced, so the uniform input power will significantly advance. With the RXPE electric arc furnace electrode regulator (Fer), the melting operation of the electric arc furnace will be more stable in the same operation process The situation of arc extinguishing will be significantly reduced, so the uniform input power will significantly advance, which will shorten the melting time and to some extent advance the melting power. It will shorten the melting time and to some extent advance the melting power.

(3) The electrode consumption has decreased. The RXPE electric arc furnace electrode regulator (FER) greatly improves the electrode forward response speed and effectively reduces electrode cracking incidents. Together, it can effectively prevent electrodes from immersing in the liquid pool, thereby reducing electrode consumption and saving melting costs.

(4) Reserved data interface for reactive power estimation in electric arc furnaces, aimed at integrating with the reactive power compensator of electric arc furnaces to improve response speed. The Refining Furnace Regulator/Electrode Regulator (FER) can provide/output the policy value of the instantaneous reactive power demand of the three-phase electric arc furnace, and together achieve stable electrode regulation. This policy of reactive power demand can be used to provide/output the policy value of instantaneous reactive power demand for three-phase electric arc furnaces for non refining furnace regulators/electrode regulators (Fer) in the furnace, together achieving stable electrode regulation. This policy of reactive power demand can be used for the purpose of rapid control of reactive power compensators in furnaces. Compared with traditional reactive power compensation methods, this solution introduces a pre query of the reactive power demand of the furnace, and further advances the fast control goal of the dynamic reactive power compensator's compensating power compensator Compared with traditional reactive power compensation methods, this solution introduces a pre query of the reactive power demand of the furnace, and further advances the compensation speed of the dynamic reactive power compensator. It improves the reactive power compensation effect of the refining furnace and significantly reduces the impact of the electric arc furnace on the power grid.

The fully automatic regulator for electrode lifting in the refining furnace incorporates advanced control concepts from abroad and uses three separate impedance measurement methods to control the superimposed current, achieving automatic operation. In the process of practical training, it has the effect of maintaining the operation switches and transformer taps of steelmaking equipment, reducing arc breaks, avoiding electrode breakage, reducing training time by advancing power, and saving energy, which has reduced production costs for the enterprise's practical production.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province