Jun. 23, 2025

As a professional term in the field of metallurgy, the electric furnace oxygen lance has been officially defined since 2019. It refers to a water-cooled oxygen lance that blows oxygen into the molten pool to promote the smelting reaction during the electric furnace smelting process. This equipment is usually inserted at a certain angle from the furnace door or furnace wall and is located above the liquid surface in the furnace. Each electric furnace is generally equipped with 2 to 3 oxygen lances, which have a short blowing distance and relatively dispersed impact points to ensure the uniformity of oxygen distribution in the molten pool.

The electric furnace oxygen lance is a core component of electric arc furnace steelmaking technology, and plays a vital role in improving smelting efficiency and reducing energy consumption. In the complex process of electric furnace steelmaking, oxygen lance technology plays the role of the core technology of modern steelmaking, and its application effect directly affects the production efficiency and energy consumption level of the electric furnace. By precisely controlling the synergy of power supply and oxygen input, the oxygen lance has become a key link in accelerating the production rhythm and achieving energy conservation and emission reduction goals. Especially when the electric furnace uses molten iron as raw material, oxygen blowing from the oxygen lance can significantly enhance the chemical reaction heat of the smelting process, thereby further improving the overall thermal efficiency.

The application of electric furnace oxygen lances has brought many significant benefits: it greatly improves the oxygen blowing efficiency, shortens the smelting cycle, reduces the consumption of oxygen blowing tubes, and thus reduces production costs; at the same time, it also improves the operating environment of workers and reduces labor intensity. In addition, by optimizing the morphology and combustion conditions of the oxygen jet, the electric furnace oxygen lance also promotes the effective utilization of heat in the smelting process, making an important contribution to energy conservation and consumption reduction in the steel industry. In summary, the electric furnace oxygen lance is an indispensable and efficient and energy-saving equipment in electric arc furnace steelmaking.

The main types of furnace oxygen lances include water-cooled oxygen lances and consumable oxygen lances, which are mainly used to blow oxygen into the furnace during the electric furnace smelting process. The water-cooled oxygen lance has the advantages of high oxygen utilization and high degree of automation, but it cannot directly contact the molten steel during operation. The consumable oxygen lance can contact the molten steel earlier in the furnace, but it needs to be replaced regularly, and the operation is more troublesome.

Specifically, the electric furnace oxygen lance is mainly divided into the following types:

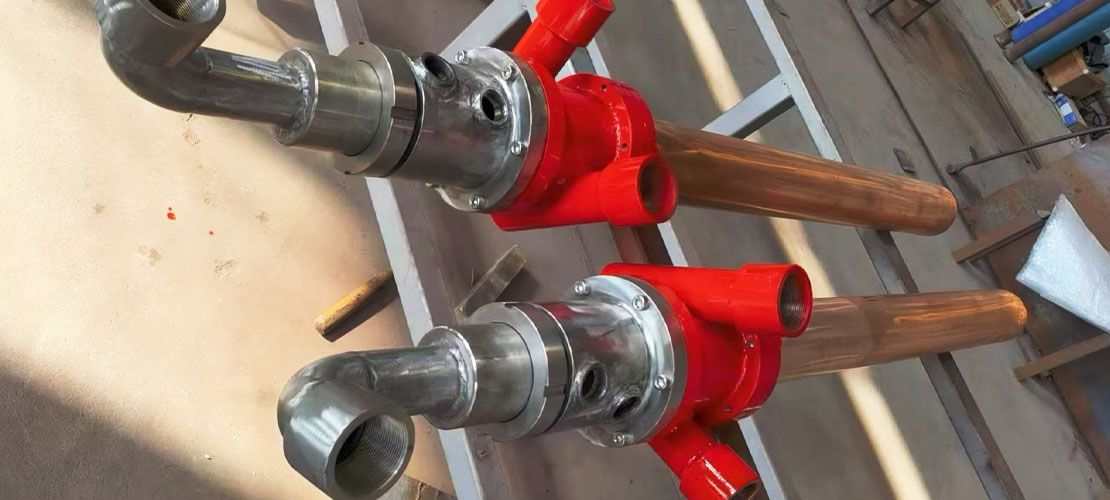

Water-cooled Laval Oxygen Lance:

It is mainly used for strong oxygen blowing in the process of electric furnace smelting. It consists of a lance head and a lance body. The oxygen supply channel of the lance head is connected to the oxygen supply channel of the lance body. The water-cooled Laval oxygen lance is mainly composed of a lance head and a lance body. The oxygen supply channel of the lance head is connected to the oxygen supply channel of the lance body. Among them, the lance body is composed of three straight tubes in an inner and outer set. A water-cooling channel is formed between the two adjacent layers of the straight tube wall, and the inner straight tube is the oxygen supply channel; its lance head adopts a bending structure so that a certain oxygen blowing angle can be achieved when in use.

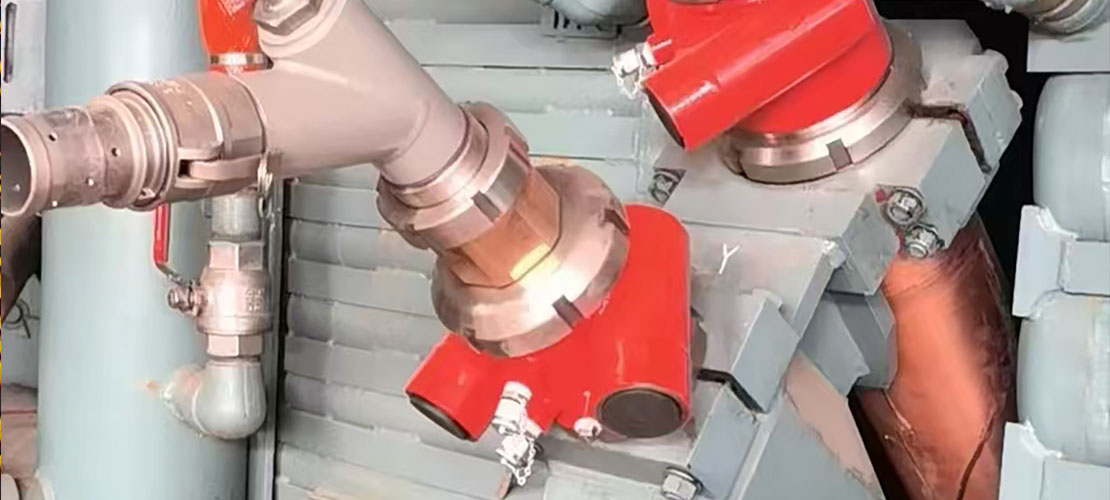

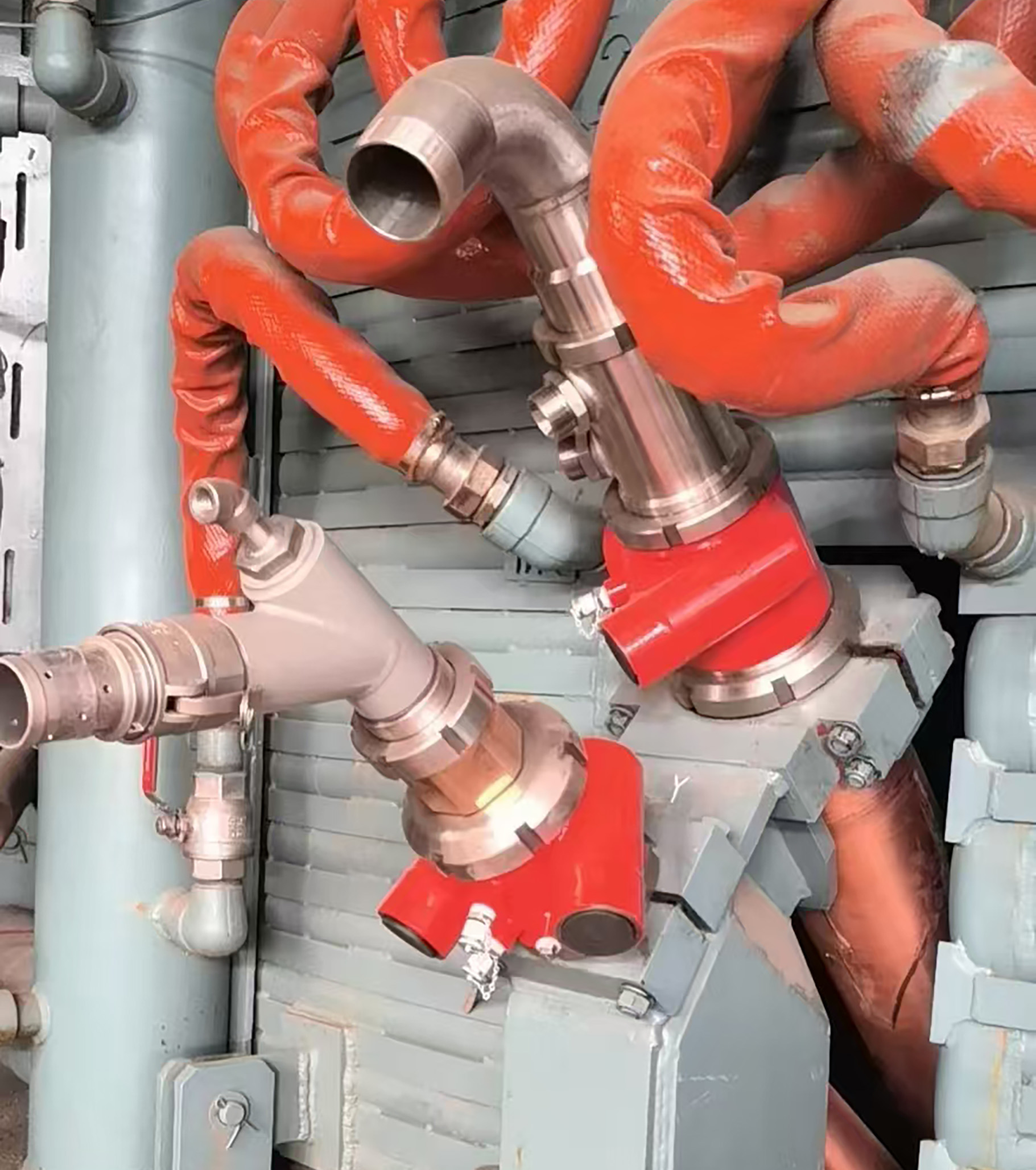

Water-cooled Furnace Door Carbon Oxygen Lance:

The water-cooled furnace door carbon oxygen lance refers to the furnace door oxygen blowing equipment in which the oxygen blowing device is cooled by water. Oxygen blowing and carbon powder spraying can be made into one piece or separated. The oxygen nozzle adopts a double-hole supersonic nozzle design to enhance the effect of splashing and stirring. The water-cooled oxygen lance is a specially designed water-cooled oxygen lance made of three layers of steel pipes (outer diameter φ122~219mm) and inlaid with copper nozzles. It is mainly used for blowing oxygen at the furnace door and has the advantages of high oxygen utilization rate and good foam slag effect.

Consumable Furnace Door Carbon Oxygen Lance:

Consumable furnace door carbon oxygen lance can contact with molten steel earlier in the furnace, which is conducive to scrap steel cutting.

Furnace Wall Oxygen Lance:

Furnace wall oxygen lance is used to eliminate the cold zone in the furnace and ensure balanced melting of the charge. It has functions such as decarburization and fluxing.

EBT Oxygen Lance:

EBT oxygen lance is used to melt scrap steel in the EBT area, increase the molten pool temperature in the EBT area, and even out the molten pool composition.

Bundled Oxygen Supply Technology:

Bundled oxygen supply technology uses bundled jets and has multiple functions such as preheating, melting, heating, and decarburization.

How to efficiently input chemical energy (oxygen, fuel, etc.) into the electric arc furnace according to the production process directly affects the quality, energy consumption and production operation rate of steel, and is the key to electric arc furnace steelmaking. As a result, various forms and functions of electric arc furnace chemical energy enhanced input technology have been developed.

The oxygen blowing equipment for the furnace door of the electric arc furnace is divided into two categories according to the water cooling method, one is the water-cooled furnace door carbon oxygen gun, and the other is the consumable furnace door carbon oxygen lance. The water-cooled furnace door carbon oxygen lance has the advantages of high oxygen utilization rate, good foam slag effect, stable decarburization and dephosphorization effect, and high degree of automation, but it cannot contact with molten steel during operation, which has certain limitations. The consumable furnace door carbon oxygen gun can start cutting scrap steel earlier and contact with molten steel in the furnace, and the activity space in the furnace is large, but the oxygen blowing pipe needs to be connected every once in a while during operation, which is more troublesome.

The purpose of the arc furnace wall oxygen supply is to eliminate the cold zone in the furnace, ensure the balanced melting of the charge, and use the furnace wall modular control to spray pure oxygen to increase the specific power input of the arc furnace and improve production efficiency. The furnace wall oxygen gun mainly has the functions of decarburization, fluxing, secondary combustion and foam slag making. Compared with the traditional installation method, the installation position of the furnace wall oxygen lance is closer to the molten pool, and the distance from the jet to the molten pool is shortened by 40%-50% compared with the traditional installation method, which can greatly improve the decarburization speed and oxygen utilization efficiency of the molten pool; the combustion in the molten pool can be organically combined with the combustion above the molten pool, which improves the thermal efficiency of the smelting process; multi-point injection can be achieved in the furnace, and the oxygen blowing amount and carbon powder blowing amount can be accurately controlled, and the foam slag effect is good.

Modern electric arc furnaces all use eccentric bottom steel tapping (EBT) technology, making the EBT area one of the cold areas in the electric arc furnace, resulting in slow melting of scrap steel in this area and large differences in the composition of the molten pool from the central area. Installing an EBT oxygen lance on the upper side of the eccentric furnace for oxygen blowing and melting can promote the melting of scrap steel in the EBT area, completely solving the problems that the scrap steel in the EBT area has not melted during steel tapping and the steel tapping port cannot be opened. After the molten pool appears, the molten pool temperature in the EBT area is increased to even out the composition of the molten pool. When tapping steel, the temperature and composition of the EBT area differ from the temperature and composition of the furnace door area by only 0.5%-1.0%.

Aiming at the problems of fast attenuation of supersonic gas jet velocity and low oxygen utilization rate, cluster jet technology has been developed and applied. An annular protective gas flow (generated by combustion of gas and oxygen) is set around the main oxygen jet, so that the length of the supersonic core section of the main oxygen jet is extended to form a jet similar to a laser beam. The kinetic energy loss of its oxygen stream is reduced, and it has extremely strong penetration and stirring power, which can realize high-speed oxygen supply to the molten pool for decarburization, improve the uniformity of heat and composition in the furnace, and have a very obvious effect on promoting slag reaction, uniform steel composition and temperature, improving oxygen utilization rate, and improving metal recovery rate. The USTB cluster oxygen supply technology developed by the University of Science and Technology Beijing is more suitable for the structural characteristics of domestic electric arc furnace steelmaking charge, reaching the international leading level, and has been applied to more than 100 electric arc furnaces at home and abroad.

Consumable furnace door carbon oxygen lance refers to a consumable equipment in which the oxygen blowing pipe and carbon powder spray pipe gradually melt into the molten steel during the smelting process. The diameter of the consumable pipe is generally much smaller than that of the water-cooled oxygen lance, so the oxygen blowing and carbon spraying are more flexible. The consumable furnace door carbon oxygen lance is represented by the German BSE multifunctional combination lance.

The German BSE multifunctional combination gun LM2 (as shown in the figure) is a combination of oxygen gun and carbon gun manipulators and side bending temperature sampling manipulators. The full set of LM2 manipulators consists of a solid steel structure and is installed on a cylinder together with two rotating hands. The upper rotating hand supports the oxygen lance and carbon gun drive device, and the lower rotating hand supports a chassis for installing a temperature sampler. Sampling and temperature measurement are carried out under the operation of uninterrupted power supply, uninterrupted oxygen blowing and carbon blowing.

The 70t ultra-high power DC arc furnace of Xinjiang Bayi Iron and Steel Co., Ltd. adopts the spray gun manipulator developed by the German BSE company. Daye Special Steel's 70t ultra-high power arc furnace adopts the multifunctional combination lance LM2.

At present, the furnace door lance of the electric furnace basically adopts a water-cooled design. Since the water-cooled oxygen lance also has certain shortcomings, Baden Steel Company has studied and applied a consumable furnace door lance, which has the function of spraying lime and spraying carbon powder to make foam slag. Compared with the water-cooled oxygen gun, its advantages are high operating safety factor, large spraying angle, and can directly cut scrap steel. The disadvantage is that the oxygen blowing pipe is expensive and cannot blow oxygen continuously.

The coherent jet oxygen lance technology is a new type of oxygen blowing technology that can solve the shortcomings of the traditional supersonic oxygen gun with short spray distance, small impact force, and low oxygen utilization rate. It mainly uses the envelope formed by the combustion of the medium to protect the main oxygen flow. The outlet Mach number of the coherent jet oxygen gun can reach about 2.0, and the jet distance in the technical state can reach 1.2~2.1m. It can be directly installed on the furnace wall to achieve functions such as fluxing and decarburization.

The main benefits of using a clustered jet oxygen lance in an electric furnace are as follows:

(1) It has multiple functions such as oxygen blowing, combustion and secondary combustion, and realizes centralized automatic control, thereby reducing the facility cost of each system and the process cost of separate operation.

(2) Due to the setting of the combustion function, scrap steel can be preheated and melted in advance, thereby reducing electricity consumption (at least 20kW?h per ton of steel).

(3) Due to its strong impact and stirring capabilities, the utilization rate of oxygen and injected carbon powder is improved, thereby reducing the consumption of oxygen and carbon powder.

(4) Due to the setting of the secondary combustion function, the CO combustion in the furnace is fully utilized to increase the furnace temperature, thereby reducing energy consumption.

(5) Due to the reduction of splashing, the iron content in the slag is reduced, the metal recovery rate is improved and the maintenance cost of the furnace body is reduced.

The clustered oxygen lance can cut and melt scrap steel more quickly, and can blow oxygen into the molten pool more effectively, greatly improving the utilization rate of oxygen. First, turn on the auxiliary oxygen system, delay a certain time to turn on the compressed air system, and then delay a certain time to turn on the fuel (or gas) system, and at the same time supply the main oxygen. When shutting down, the fuel oil and main oxygen should be shut down first, and then the compressed air and auxiliary oxygen should be shut down in sequence. Automatic alarm processing prevents the oil pressure from exceeding the compressed air pressure and causing serious safety accidents.

The EBT oxygen lance is a device used in electric arc furnace steelmaking. It improves the smelting efficiency by adjusting the oxygen jet. It adopts a telescopic drive EBT oxygen gun and adjusts the position of the gun according to the smelting conditions. The patented technology in 2019 optimizes the jet structure and adopts the design of ring oxygen holes and natural gas holes to improve the decarburization speed and the temperature uniformity in the furnace. The procurement project in 2023 shows that it is still widely used in modern steel production.

The EBT oxygen lance adopts a telescopic drive, and the gun position can be adjusted according to the smelting conditions to optimize the oxygen jet effect. The patented technology in 2019 was further improved. The main oxygen hole is surrounded by the ring oxygen hole, and the natural gas hole is added on the periphery to enhance the clustering effect, so that the oxygen jet penetrates the slag surface into the molten steel, improves the decarburization speed and reduces consumption.

In the EBT electric arc furnace, three oxygen lances are installed on the water-cooled plate, and the jet direction takes into account both the furnace bottom and the EBT area to improve the penetration depth and stirring intensity. At the same time, the EBT area is covered to melt the cold steel and quickly slag, stabilizing the arc and dephosphorization conditions. As of 2019, this configuration effectively reduced oxygen reflection accidents and achieved efficient and stable production.

In order to achieve slag-free steelmaking, modern electric arc furnaces all use eccentric bottom steelmaking (EBT) technology. This not only reduces the amount of slag in the steelmaking process, but also shortens the smelting cycle and reduces the temperature drop of steelmaking. However, it also makes the EBT area one of the cold areas of UHP-EAF, resulting in a slower melting rate of scrap steel in this area, and a large difference in the composition of the molten pool from the central area.

Chemical reaction heat accounts for a considerable proportion of the energy input of electric furnace, reaching 20%-30%; especially after the electric furnace uses molten iron, the proportion of chemical heat reaches 40%-50%, which is a feature of modern electric arc furnace steelmaking process; oxygen technology is a concentrated embodiment of modern new technology, and the combination of power supply and oxygen supply is an important means for electric furnaces to improve production rhythm and save energy and reduce consumption.

Under oxygen blowing conditions, the theoretical calorific value generated when 1kg of each element in the molten pool is oxidized.

Under oxygen blowing conditions, the theoretical calorific value generated when 1kg of each element in the molten pool is oxidized is shown in the following table:

Elements | Product | Reaction heat | Relative cost① (reference value)

| |

kJ/kg | Kw·h/kg | |||

Al | Al2O3 | 30.995 | 8.61 | 3.7 |

Si | SiO2 | 32.157 | 8.93 | 3.2 |

Mn | MnO | 6.992 | 1.94 | 6.0 |

Fe | FeO | 4.775 | 1.33 | 1.8 |

C | CO | 9.159 | 2.54 | 0.5~0.6 |

C | CO2 | 32.761 | 9.10 | 0.3~0.6 |

① Assume that the electricity price per kw/h is 1.

Blowing oxygen in electric furnace steelmaking is one of the important means to strengthen electric furnace smelting. Using steel pipes to insert into the molten pool to blow oxygen is a commonly used method. In order to make full use of the chemical energy in the furnace, the oxygen consumption per ton of steel has gradually increased in recent years; at the same time, considering the poor working conditions, unsafety, and unstable oxygen blowing efficiency of manual oxygen blowing, the electric furnace door gun mechanical device has been developed. Such as the self-consumable oxygen gun device developed by Germany's BSE company and the water-cooled oxygen gun device developed by Germany's Fuchs, the United States' Berry, and the United States Combustion Company.

Because the self-consumable oxygen gun consumes a large number of oxygen blowing tubes, it is rarely installed in newly built electric furnaces. The function of the furnace door gun device is to blow oxygen to assist melting and refining and blow carbon powder into the molten pool to make foam slag.

The use effect of the comprehensive electric furnace door gun is: improve oxygen blowing efficiency, shorten smelting time by 5-15min; save 80% to 90% of oxygen blowing tubes, reduce the cost of 15-30 yuan per ton of steel; improve the working conditions of workers, and replace 90% of manual oxygen blowing.

The door gun consists of a water-cooled oxygen lance and a door lance; the mechanical system consists of a large arm rotation, a gun body rotation, a gun body swing and a lifting system; the oxygen gun configured on the door gun device can assist melting during the melting period and decarbonize and refine during the oxidation period. The door gun device is equipped with a carbon gun, which is mainly used to make foam slag.

The fuel used by the burner is solid, liquid and gas. Among liquid fuels, light diesel is currently more preferred because it is easy to use, clean, and easy to maintain, and it is an auxiliary fuel. Gas fuel is mainly natural gas, which is currently limited in resources in my country and is used less; while gas fuels such as coal gas are not used because of their low calorific value and large amount of waste gas. my country has developed coal-oxygen technology for solid fuels based on resource conditions, but the thermal efficiency of the injection is low, the investment is large, and the preparation, storage, transportation of pulverized coal, and the removal and separation of sulfur and ash residues in the combustion products are relatively cumbersome.

The electric furnace generates heat by arcing the electrode to make steel. The steel material slowly melts from the center of the electrode to the surrounding area, with large heat loss and long melting time. The oxygen-burning gun, also known as the oxygen-burning nozzle, is arranged on the furnace wall in the cold zone of the electric furnace. It relies on the reasonable matching of the burner and the arc power supply to achieve balanced melting of the scrap steel.

The efficiency of the burner depends on:

(1) The scrap steel temperature and the heating area. If the scrap steel temperature is high and the heating area is large at the beginning of melting, the burner efficiency can reach 80%;

(2) Determine the appropriate oxygen-oil ratio at different stages. When the scrap steel is close to being melted, the amount of burner oil should be reduced. In addition to oil, the fuel used by the burner is also natural gas or coal powder. Oxygen burners are also used in flues to preheat scrap steel, but attention should be paid to environmental protection.

Latest News

Causes of Burning of Converter Oxygen Lance

Jun. 24, 2025

The Complete Guide to Electric Furnace Oxygen Lance

Jun. 23, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province