Aug. 20, 2025

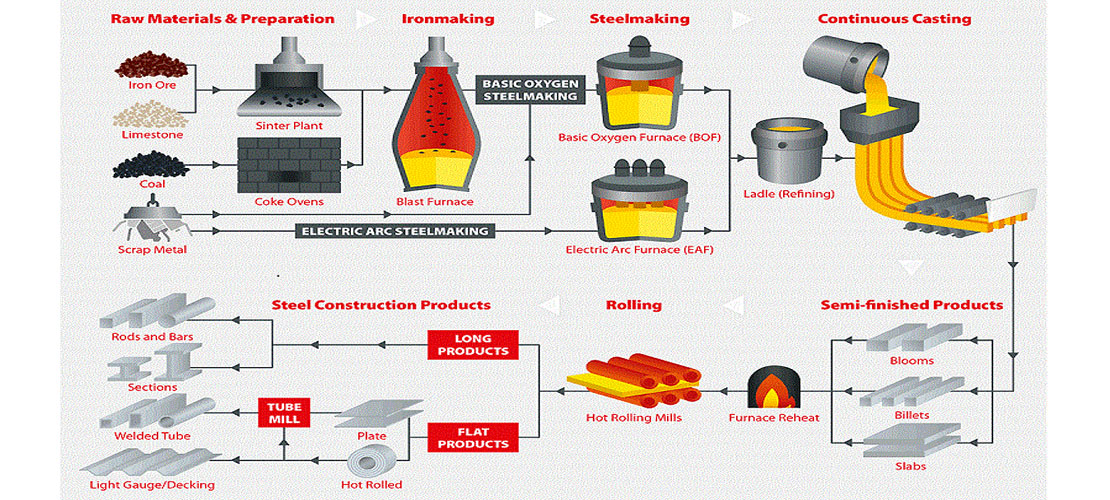

What is short-process Electric Furnace Steelmaking? In the steel industry, there are two main smelting processes: the long "blast furnace-converter" steelmaking process, which uses iron ore as the primary raw material, commonly known as converter steel; and the short-process Electric Furnace steelmaking process, which uses scrap steel as the primary raw material, commonly known as electric furnace steelmaking. Unlike the long-process steelmaking process, the short-process Electric Furnace steelmaking process uses scrap steel as its primary raw material, and eliminates the coking, sintering, and blast furnace ironmaking steps, which are relatively polluting, energy-intensive, and have high carbon emissions.

The "short-process" steelmaking process specifically refers to a compact production process that combines electric arc furnaces with continuous casting and rolling. It primarily consists of raw material preparation, electric arc furnace smelting, refining, continuous casting, and rolling. Compared to the traditional long-process (blast furnace-converter process), it offers advantages such as simpler equipment, smaller footprint, lower investment, shorter construction period, and more flexible production organization. Short-process Electric Furnace Steelmaking is one of the key paths for the steel industry to achieve a low-carbon transition. The use of short-process electric furnace steelmaking technology significantly reduces carbon emissions. With the rapid development of the new energy industry, the continuous improvement of differentiated electricity pricing policies across regions, and the increasing abundance of green electricity resources, the electricity costs of electric furnace steelmaking will continue to decline. Furthermore, relevant departments are gradually improving their policy support for low-carbon development in areas such as capacity replacement, environmental protection, and land use, and carbon emission constraints are becoming increasingly stringent. Advances in short-process electric furnace steelmaking technology will also contribute to the further development of electric furnace steelmaking.

1. Low Investment and Short Construction Period: The investment in short-process electric furnace steelmaking is approximately half or even a quarter of that of traditional long-process steelmaking, significantly shortening the construction period.

2. Low Production Costs and High Labor Productivity: Due to low energy consumption, production costs are also reduced, and labor productivity is high.

3. Environmental Advantages: Pollutant emissions from short-process steelmaking, particularly sulfur dioxide and nitrogen oxides, are far lower than those from traditional long-process steelmaking, making it environmentally friendly.

4. Strong adaptability to raw materials: Electric furnace steelmaking is highly adaptable to scrap steel, effectively utilizing scrap resources.

5. Flexible production organization: Electric furnace steelmaking can flexibly adjust production according to market demand to meet the production needs of different steel grades.

6. Future Development: With the increasing demand for low-carbon development worldwide and the implementation of my country's energy-saving, environmentally friendly, and low-carbon policies, electric furnace steelmaking will place greater emphasis on green and low-carbon development, high efficiency, low cost, and intelligent upgrades.

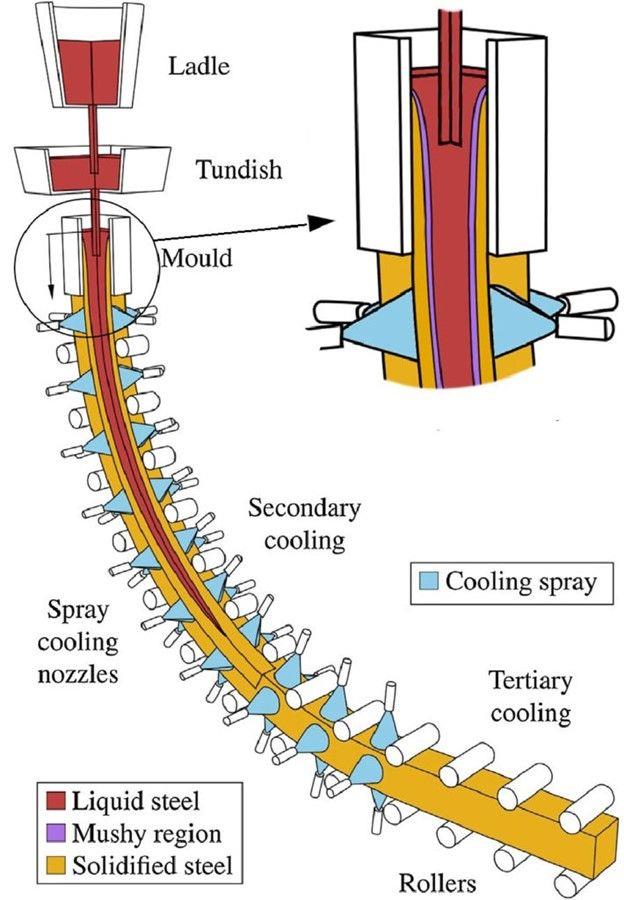

Continuous casting is a key step in material conversion in the steel and metallurgical production process, and a crucial stage for energy conservation, consumption reduction, and improved steel performance. Modern continuous casting technology and engineering actively leverages technological advancements in interdisciplinary and cross-technical fields to transform and enhance the simple material conversion capabilities of traditional casting machines. This allows for the stable and reliable casting of qualified molten steel into qualified ingots and even near-net-shape products, efficiently and with high quality. This effectively enhances the intrinsic quality of the as-cast ingot (such as compositional uniformity and microstructure density), and provides valuable information on the ingot's quality status for the subsequent hot rolling process. This truly fulfills the crucial role of continuous casting in connecting the steel refining and hot rolling processes, and even in coupling the upstream and downstream processes.

Conventional continuous casting primarily relies on surface water cooling to control ingot solidification and quality, which has limited efficiency and effectiveness. Common ingot internal quality issues, such as center porosity and excessive center segregation, are virtually unavoidable in conventional continuous casting, making substantial improvement in ingot internal quality difficult. Based on solidification principles, researchers have long sought to couple various processing techniques or physical field control theories to continuous casting process control. Among these, thermal tracking and dynamic soft reduction in continuous casting represent one of the most promising and increasingly mature advanced technologies in terms of both principle and overall effectiveness.

This is the first two-stage dynamic secondary cooling and dynamic soft reduction control model independently developed and implemented in China for modern large square billet casting. By timely tracking the solidification endpoint of the billet and implementing appropriate dynamic reduction control techniques in the solidification phase of the billet through the drawing and reduction rolls based on the shrinkage characteristics of the steel, this model effectively controls central porosity and segregation in high-carbon equivalent billets and significantly improves the overall mechanical properties of the rolled product.

Dynamic secondary cooling control for continuous casting is an upgraded version of the conventional water meter method for automatic water distribution. It is a two-stage dynamic secondary cooling control model for continuous casting independently developed and commercially implemented in China. It avoids the excessive human intervention associated with conventional single-stage control models. Based on the thermal characteristics of the steel grade and the requirements for ingot quality control, a reasonable target cooling strategy is formulated. By appropriately tracking the pouring temperature and casting speed, the secondary cooling water volume is dynamically controlled. Ingot quality is ensured by ensuring a reasonable and relatively stable cooling process for the ingots of specific steel grades and cross-sections. Different cooling control models are required for ingots of different cross-sections due to differences in geometry and heat transfer characteristics. Slabs are best described using a one-dimensional control model, round ingots can also be described using a one-dimensional cylindrical coordinate model, and square ingots must use a two-dimensional control model.

Tracking and recording key equipment and process states during the continuous casting process ensures a clear understanding of product quality throughout the production process. Based on the characteristics of currently advanced domestic casting equipment, an online ingot quality prediction model has been developed using artificial neural network technology to predict common ingot quality issues such as center segregation, intermediate cracks, and center cracks. This model's key feature is that, once trained with appropriate samples based on customer production conditions, it possesses intelligent self-learning capabilities after online application, resulting in high prediction accuracy and meeting on-site requirements. This provides important guidance for identifying hot charging and hot delivery, or abnormal casting conditions with undetermined quality. Figure 4 shows that the prediction accuracy of the intelligent quality prediction model can be continuously improved through self-learning during use.

The continuous casting process involves complex interactions between heat transfer, mechanical forces, and thermal deformation. These interactions not only affect slab quality and its control strategies, but also significantly impact casting equipment such as the mold copper plate and roller train, ultimately affecting the stability and reliability of the equipment. Currently, finite element (FEM) analysis is a key tool for understanding and mastering the complex physical phenomena of the continuous casting process. To this end, we systematically studied the high-temperature thermal properties of several steel grades using modern high-temperature thermal property testing technology. We also used thermo-elastic-plastic coupled numerical simulation techniques to investigate the heat transfer and deformation within the continuous casting mold, as well as the temperature distribution and deformation patterns of the slab in the secondary cooling roller train. The characteristics and countermeasures of the lateral cooling temperature distribution of slabs, as well as the heat transfer and deformation characteristics of slabs under the roll gap taper or light reduction process were revealed earlier at home and abroad.

1 Ladle Support Device

During continuous casting, molten steel is generally supplied to the continuous casting machine with a ladle. The equipment that transports the ladle to the top of the intermediate tank and supports it is called ladle support equipment.

Currently, there are four types of ladle support equipment: crane-lift ladle type, ladle support type, ladle car type, and ladle turret type.

(1) Crane-lift ladle type: The ladle is lifted to the specified position by a crane. It is rarely used.

(2) Ladle support type: The ladle is supported at the specified position by a support. This method can realize continuous furnace casting, so it is rarely used.

(3) Ladle car type: The ladle car is a traveling trolley that can support two ladles and straddle the intermediate tank. This device, the continuous casting machine, and the ladle crane must be located in the same span of the plant. In addition, to ensure continuous furnace casting, one continuous casting machine must be equipped with two ladle cars. The narrow pouring platform of this support device limits the installation of various other machines. Moreover, since it is concentrated with the continuous casting machine, it interferes with each other and affects operation. (4) Ladle turret: The ladle turret consists of a fixed part and a rotating part. The fixed part is fixed to the foundation with bolts, while the rotating part and the fixed part are connected to the bearing of the rotating cup. In addition, the rotating arm of the turret can rotate 180° and can be raised and lowered. The two ends can also simultaneously place the ladle and install the metering device. This device has a relatively simple structure, is easy to operate from a distance, and is safe, reliable, and efficient. It is the main equipment currently used.

2. Tundish

The tundish is primarily used to receive molten steel from the ladle and distribute it to the various molds. Therefore, it not only controls the flow rate of molten steel into the mold and maintains a uniform temperature, but also creates conditions for non-metallic inclusions in the steel to float up. In other words, when the molten steel level in the tundish is maintained constant, it also stabilizes the pressure.

3. Tundish Car

Its primary function is to move the tundish. It generally features three functions: travel, lifting, and fine-tuning the nozzle position. This meets operational requirements even for continuous furnace pouring, which requires rapid tundish exchange.

Tundish cars are driven by either electric or hydraulic means. Small-capacity tundishes are electrically powered, while large-capacity ones are typically hydraulically powered. Load cells can also be installed on the tundish car tracks to measure the weight of the molten steel.

4. Mold

The main function of the mold is to cool and solidify the molten steel into a shell of a certain thickness to prevent cracking when the billet is pulled from the mold. The mold is generally made of pure copper or copper alloy, which has good thermal conductivity and minimizes thermal deformation. Grooves or holes are drilled inside to allow high-pressure cooling water to flow at a rate of 5 to 10 m/s. To improve the wear resistance of the mold wall, chrome plating is typically applied to the inner surface. Molds can generally be categorized into three types: integral, tubular, and assembled.

5. Mold Vibration Device

The mold vibration device causes the mold to reciprocate, primarily to prevent molten steel from adhering to the mold, thereby preventing the solidified shell from breaking and causing steel breakouts. It also improves heat conduction within the mold and improves billet quality. Lubricant can also be introduced into the mold.

6. Secondary Cooling System

The solidified shell of the billet exiting the mold is very thin, approximately 10 to 30 mm thick, and the interior is still filled with molten steel. Surface defects can cause molten steel to leak out. Therefore, to ensure the most complete solidification possible of the billet exiting the mold, further cooling is necessary, a process known as secondary cooling.

7 Billet Straightening

Bill straightening device is also called billet straightening roller. Its main function is to continuously pull the billet out of the crystallizer at an adjustable speed. In addition, it can also straighten the bent billet on the arc continuous casting machine and output it in the horizontal direction.

8 Cutter

The function of the cutter is to cut the continuously cast billet into finished products according to the specified length. There are two common cutters.

(1) Flame cutting. The gas used in flame cutting is mainly acetylene or propane and high-pressure oxygen is used for combustion. Some also use coke oven gas-oxygen cutting. Advanced flame cutting should include a travel device, a cutting gun device, an end face detection device and a billet clamping device. The operation is common, manual, semi-automatic and fully automatic. Flame cutting is slow, the metal loss is about 1%~2%, and the pipeline is also complex and prone to malfunction and environmental pollution.

(2) Mechanical shearing. At present, the most common mechanical shearing is flying shear. Although the flying shear is complex, its operation is simple and reliable, with minimal metal loss and high productivity.

9 Dummy Bar

The dummy bar extends the dummy head into the mold as a live bottom. After pouring begins, the molten steel and the dummy head coalesce. Simultaneously, it transmits the pulling force of the pull rollers to the billet, gradually pulling the billet out of the mold and along the guide mechanism of the continuous casting machine.

The dummy bar consists of two parts: the dummy head and the dummy body. Vertical continuous casting machines sometimes use a single-piece structure to prevent wear and deformation.

Curved continuous casting machines, on the other hand, use a chain-link structure with unidirectional flexibility. Dummy heads come in various types, including dovetail slot, pin, and hook, with the dovetail slot type being the most common.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province