May. 10, 2025

The abstract introduces the application technology of high-temperature flue gas waste heat utilization in ferroalloy submerged arc furnaces. Based on practical production, the thermodynamic process, economic benefits, and environmental benefits of this technology are analyzed, opening up a new path for energy conservation and emission reduction in the ferroalloy industry.

Keywords: ferroalloy, submerged arc furnace, flue gas waste heat utilization, energy saving

Ji Xiaochang Hu Shaoyong

(Yunnan jianshui Manganese Co.,Ld., Jianghui 654308, China)It introduces the application technology of high temperature flue gas waste heat utilization on ferroalloy submerged-arc furnace.

Abstract:Combined with the actual production, it analyzes the thermodynamic process, economie benefitsand environmental proteclion benelits, which opens up a new way for the ferroalloys industry energy conservation andemission reduction.

Keywords: ferroalloy,submerged-arc furnace, flue gas, waste heat utilization, energy conservation

A company currently operates a production line with an annual output of 200,000 tons of manganese-based alloys, utilizing one 50MVA (closed) and two 25MVA (semi-closed) ferroalloy submerged arc furnaces. To recycle the heat from the flue gas, the company has constructed a 12MW waste heat power generation system, harnessing the high-temperature flue gas waste heat from the ferroalloy submerged arc furnaces for power generation. However, even after the waste heat power generation, a portion of the flue gas waste heat (with a temperature of approximately 100°C or higher) remains unrecycled. According to statistical analysis of production data, the recovery and utilization rate of high-temperature flue gas waste heat from ferroalloy smelting is only 33.5%. This indicates that there is significant potential and room for further utilization of flue gas waste heat. Therefore, utilizing the flue gas directly after waste heat power generation for drying pellets, achieving cascade utilization of flue gas waste heat, can yield positive results in energy conservation, emission reduction, and clean production.

1.1 The Source of the Smoke and Dust is the Ferroalloy Submerged Arc Furnace, Which Smelts Raw Materials such as Manganese Ore, Coke, and Silica

Iron ore, etc. The color of smelting dust is usually yellowish-brown. The main source of dust generated during the smelting process is: under high-temperature thermal energy conditions, the material in the Submerged Arc Furnace undergoes oxidation-reduction reactions with oxygen in the air, generating CO, CO₂, and some coke powder, ore powder, and vaporized metals, which form a mixed gas. This gas enters the flue through the open mouth of the furnace and is dedusted by a fabric bag filter to obtain flue gas [1].

1.2 Main Components of Flue Gas

The main components of the flue gas from the submerged arc furnace are N₂, CO₂, SO₂, H₂O, etc. The mass fraction of each component is as follows: w(N₂) is 75% to 78%, ω(CO₂) is 15% to 18%, ω(H₂O) is 2%, and ω(O₂) is 0.2%. After the high-temperature flue gas is used for waste heat power generation, the average values of flue gas flow and temperature of three ferroalloy submerged arc furnaces are measured using tools such as Pitot tubes and thermocouples. The measured main components, flow rate, and temperature data of the flue gas are shown in Tables 1 and 2. According to Tables 1 and 2, the temperature of the flue gas after waste heat power generation is 80~130℃, and the amount of flue gas is large. If it is vented, a large amount of heat will be wasted. Therefore, the company has carried out technological transformation, using this part of the flue gas to directly dry pellets, achieving multi-level recovery and utilization of waste heat from the flue gas.

Electric Furnace | CO₂ | H₂O | N₂ | O₂ | SO₂ | Amount to |

25 MVA | 5.877 | 4.376 | 73.022 | 16.718 | 0.007 | 100 |

50 MVA | 11.32 | 1.87 | 72.96 | 13.85 | 0.00 | 100 |

Table 1 Composition of flue gas from electric furnace, %

Tab. 1 Components of furnace flue gas

electric furnace | Total flue gas volume (Nm³h) | Temperature/℃ |

50 MVA | 22×10° | 90-130 |

25 MVA | 42×10⁴ | 80-120 |

Table 2 Statistical data of flue gas flow and temperature

Tab.2 Statistical data of flue gas flow rate and temperature

2.1 Theoretical Calculation of Flue Gas Waste Heat Utilization

Calculate based on the actual production measurement data:

(1) The flue gas volume of a 50MVA Submerged Arc Furnace is 22x10⁴ Nm³/h, with an inlet temperature of 110℃ and an outlet temperature of 50℃.

After calculation, the enthalpy of flue gas at 50℃ is H₁=67.238 kJ/Nm³, and the enthalpy at 110℃ is H₂=148.911 kJ/ Nm³.

The heat utilization rate is 55%:

Q=qx(H₁-H₂)=22x10⁴x(148.911-66.534)x55%=22x104x82.377 x55% =0.996x107 kJ

The available energy for the 50MVA submerged arc furnace in the application of pellet drying technology is 1.178x107 kJ/h, which is equivalent to 0.339 t/h of standard coal.

(2) The flue gas volume of a 25 MVA submerged arc furnace is 42x10N⁴m³/h, with an inlet temperature of 100℃ and an outlet temperature of 50℃.

The enthalpy of flue gas at 50℃ is H₁=66.534 kJ/Nm³, and at 100℃ it is H=133.782 kJ/ Nm³.

The heat utilization rate is 55%.

Q=qx(H₁-H₂)=22x10⁴x(133.782-66.534)x55%=42x104x67.248 x55%=1.553x107 kJ

The available energy for the 25MVA submerged arc furnace in the application of pellet drying technology is 1.553x10^7 kJ/h, equivalent to 0.530 th of standard coal. Given that the annual operating time of the company's ferroalloy submerged arc furnace is 300x24=7200 hours, the annual available heat, converted to standard coal, is (0.339+0.530)x7200=6256.8 tons.

Based on the on-site data, the moisture content of wet pellets is 12% to 15%, and the required moisture content after drying is 1% to 3%. The calculated values are 13.5% moisture content for wet pellets and 2% moisture content for dry pellets. The calculation of standard coal required for drying one ton of pellets is as follows: the amount of water that needs to be evaporated per ton of pellets is Q=1x(13.5%-2%)=0.115 t.

Upon investigation, the heat required for the evaporation of 1 ton of water is 2.568x10^9 kJ, equivalent to 0.34 tons of standard coal.

The standard coal required for drying a ton of pellets is: m=0.115x0.34-0.039 t.

The amount of pellets that can be dried throughout the year using the available waste heat from the flue gas of the ferroalloy submerged arc furnace is M=6256.8/0.039=160430.769 t

In summary, if three ferroalloy submerged arc furnaces operate at full capacity, the available waste heat from their flue gas can be converted into 6,256.8 tons of standard coal per year, and the total amount of pellets that can be dried throughout the year is 160,430.769 tons.

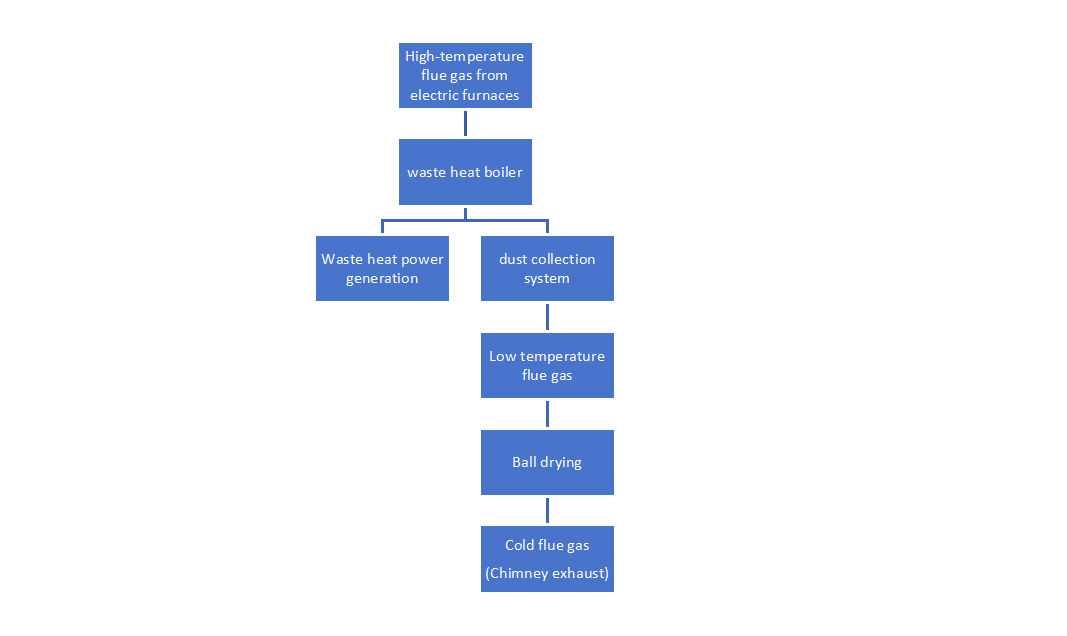

2.2 Process Flow for Waste Heat Utilization of High-temperature Flue Gas from Ferroalloy Submerged Arc Furnace (see Figure 1)

Figure 1 Process flow of flue gas waste heat recovery and utilization [2-3]

Fig.1 Process flow diagram of flue gas waste heat recovery and utilization

2.3 Pellet Quality Analysis

The pellets are dried using a continuous drying method, with a drying cycle typically lasting 5 days. The dried pellets are directly returned to the ferroalloy submerged arc furnace for use. Random samples of the dried pellets are taken to measure their compressive strength, and the quality of the actual production pellets is tested and analyzed. The measured compressive strength values of the dried pellets are presented in Table 3.

The data in Table 3 reveals that the pellets dried using waste heat from ferroalloy submerged arc furnace flue gas exhibit high strength, with an average value exceeding 3500N/cm². The pellet quality is stable, and the strength is higher than that achieved by traditional drying methods (strength values only range from 2000-3000 N/cm²), fully meeting the material requirements for ferroalloy smelting [4].

Dry Ball Sample | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Average Value |

Sample 1 | 3.510 | 3450 | 3600 | 3730 | 3550 | 3620 | 3680 | 3520 | 3582 |

Sample 2 | 3480 | 3560 | 3780 | 3.720 | 3510 | 3.810 | 3430 | 3620 | 3613 |

Sample 3 | 3380 | 3480 | 3590 | 3.630 | 3540 | 3.610 | 3.390 | 3600 | 3528 |

Table 3 Compressive strength values of pellets

Tab. 3 Pellet compressive strength values

3.1 Economic Benefit Analysis

Since the completion and commissioning of the company's pellet production line, continuous efforts have been made to optimize the process flow and improve production technology management. In the practical application of using waste heat from ferroalloy submerged arc furnace flue gas for drying pellets, the effect of waste heat recovery and utilization has been good, achieving considerable economic benefits. The analysis of pellet production benefits in 2012 is presented in Table 4.

According to the production statistics, the annual production volume of pellets is 66,090 tons. Each ton of wet pellets requires the consumption of 39 kilograms of standard coal, and the price of standard coal is 850 yuan per ton. Therefore, producing 66,090 tons of pellets requires the consumption of 2,577.51 tons of coal, which translates to a cost of 2.1909 million yuan. In other words, the annual energy cost savings from producing pellets amount to 2.1909 million yuan.

Month | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | Amount To |

Production/t | 4870 | 4683 | 4929 | 4150 | 3440 | 5190 | 5280 | 7168 | 7699 | 7038 | 5234 | 6409 | 66090 |

Table 4: Statistical Table of Pellet Production in 2012

Tab. 4 Statistical report of 2012 pellet production

3.2 Analysis of Environmental Benefits

Utilizing the production technology of drying pellets with waste heat from ferroalloy submerged arc furnaces not only fully utilizes the waste heat from the flue gas of these furnaces but also avoids the pressure on environmental protection caused by fuel. Based on the calculation of burning 2577.51 tons of standard coal per year, the complete combustion of 1 ton of standard coal will produce 2.62 tons of CO₂ and 8.50 kg of SO₂, which is equivalent to reducing the annual emissions of CO₂ and SO₂ into the atmosphere by 6753.0762 tons and 21908.835 kg, respectively. In addition, the ash content of bituminous coal is generally 10% to 15%. Reducing the combustion of 1650 tons of coal per year is equivalent to an average reduction of 206.3 tons of solid waste pollutants such as ash and slag emissions, resulting in significant environmental benefits.

The application of technology utilizing waste heat from ferroalloy submerged arc furnace flue gas for drying pellets represents an efficient utilization of waste heat in ferroalloy production, yielding significant economic and environmental benefits. This technological innovation serves as a commendable measure for the ferroalloy industry to achieve clean production, energy conservation, emission reduction, and circular economy. It paves a new path for further comprehensive utilization within the ferroalloy industry, thereby making a positive contribution to the development of energy conservation and emission reduction within the industry.

[1] Zhao Naicheng, Practical Technical Manual for Ferroalloy Production [M]. Beijing: Metallurgical Industry Press, 1998

[2] Qi Zhongyong, Li Hongxiao. Application of Waste Heat Power Generation from Submerged Arc Furnace Flue Gas. Ferroalloy, 2011, 42(2): 39-48

[3] Xie Yimin, Song Jiyuan, Hou Bincai, et al. Waste Heat Recovery and Power Generation Process System for Flue Gas from Ferroalloy Submerged Arc Furnaces. Ferroalloy, 2012, 43(1): 41-48

[4] Xu Chuancai, Drinking Alloy Metallurgy Technology [M]. Beijing: Metallurgical Industry Press 2010

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province