Jul. 29, 2025

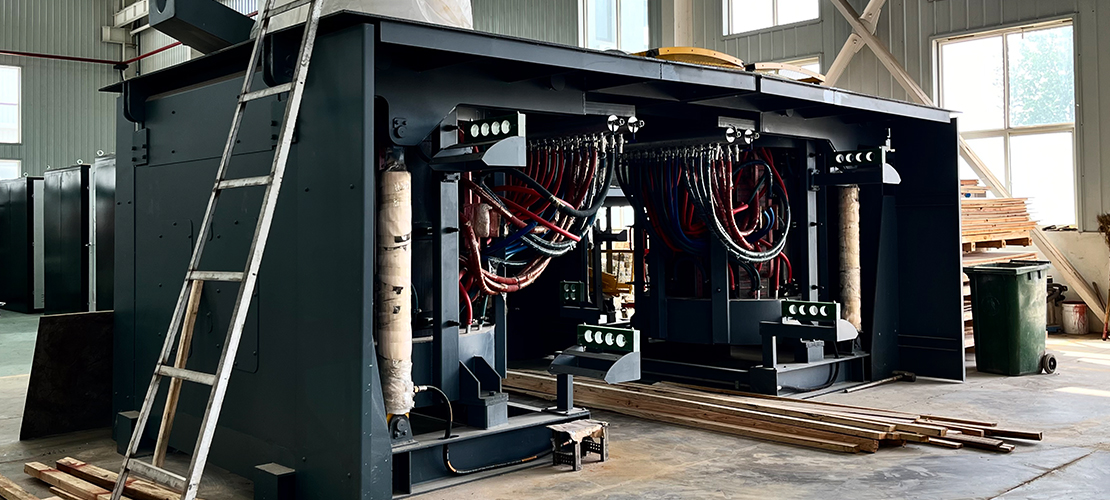

An induction furnaces is an electric furnace that applies heat by heating the metal through induction. Induction electric furnace range in capacity from less than a kilogram to a hundred tons and are used to melt steel, copper, aluminum, and precious metals.

The advantages of induction melting furnaces over most other ways of melting metals are a clean, energy-efficient, and well-controlled melting process.

Most modern foundries use this type of furnace, and many iron foundries are using induction furnaces instead of cupolas to melt cast iron because the former emit a lot of dust and other pollutants.

The heating efficiency of induction electric furnace is affected by a variety of factors, mainly including the characteristics of the workpiece material, the design of the inductor, the power supply parameters, and the temperature change requirements.

Resistivity: Materials with high resistivity are easier to heat because the eddy currents generate more heat, thereby increasing the heating efficiency of the induction melting furnaces.

Specific heat capacity and mass: Materials with low specific heat capacity and small mass heat up faster because they require less energy to reach the same temperature.

Size and thickness: Smaller or thinner workpieces are generally easier to heat than larger pieces because they have less thermal inertia and heat up more easily.

Coil design: Custom designed coils can ensure uniform heating of complex or irregularly shaped workpieces.

Coupling efficiency: Proper alignment and distance between the coil and the workpiece can maximize coupling efficiency and reduce energy losses.

Frequency: Frequency has a significant impact on heating depth. High-frequency heating mainly acts on the surface of the workpiece, while low-frequency heating can penetrate deep into the workpiece. Selecting the right frequency is critical to optimizing heating results.

Power: Higher power generally provides faster heating rates, but may also result in higher energy losses.

Temperature variation range: The induction heating system needs to be able to accommodate different temperature variation requirements. Larger temperature variations generally require more power, which may affect the efficiency of the system.

Equipment and site: The space, power, and cooling system required for the induction heating system need to be considered.

Fast heating and control: Optimizing the heating process can reduce pollution and equipment wear, thereby improving efficiency.

Maintenance and personnel: Induction heating systems require regular maintenance and skilled technicians to operate them to ensure efficient operation of induction electric furnace.

In summary, to improve the heating efficiency of induction furnaces, it is necessary to comprehensively consider the material properties of the workpiece, the design of the inductor, the power supply parameters, and the temperature change requirements, and optimize them according to the specific application, select the appropriate frequency and power, and ensure good coupling efficiency.

If you have any other questions or needs about induction melting furnaces, please feel free to contact us for support.

Latest News

Ferrochrome Production Process Flow

Jul. 30, 2025

Factors Affecting the Heating Efficiency of Induction Furnaces

Jul. 29, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province