May. 19, 2025

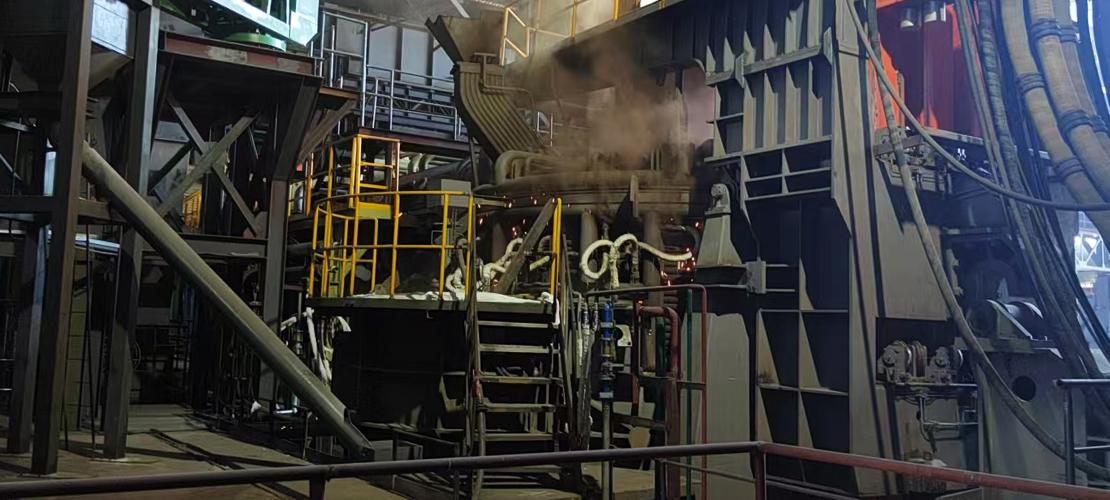

The electric arc furnace operation mode varies according to the furnace type, process requirements and degree of automation. But it mainly includes several key steps: charging and slag making.

Charging is to add raw materials such as molten iron or scrap steel into the electric furnace, which is the first step in steelmaking.

Slag making is to adjust the composition of slag, which affects the quality of steel. The whole operation process involves multiple continuous cycles, and it is necessary to control the furnace cover switch and the movement of the scrap bucket to ensure that the raw materials are smoothly added to the furnace.

There may be downtime and maintenance intervals during operation, and the goal is to use the EAF furnace as efficiently as possible.

The following are several common steelmaking electric furnace operation modes and their characteristics. Let's explore them together.

Features: Relying on operator experience, adjusting parameters by visual inspection and manual operation.

Operation process:

Charging: Manual or semi-automatic loading of scrap steel/raw materials.

Arc starting: The electrode is manually lowered to contact the scrap steel, and then pulled up to form an arc after power is turned on.

Melting period: The operator observes the state of the molten pool and manually adjusts the electrode position, voltage or current.

Refining period: Manually add alloys and slag-forming agents to control temperature and composition.

Applicable scenarios: small and old furnaces or special steel production.

Disadvantages: low efficiency, poor stability, and high energy consumption.

Features: Partial automation (such as electrode lifting), manual intervention in key steps.

Automatic arc starting: PLC controls the initial position of the electrode and the arc starting current.

Melting stage: The system adjusts the power according to the preset curve, and the operator monitors and adjusts.

Refining stage: Manually input the alloy composition target, and the system assists in calculating the addition amount.

Advantages: Balance flexibility and stability, suitable for medium-scale production.

Features: single electrode + bottom anode design (reference source: Siemens, Primetals), special control strategy required.

Operational differences:

Arc starting: Bottom anode is preheated to 800-1000°C or above to ensure conductivity. (Graphite anodes usually do not need 1000°C, conductive refractory materials may be higher)

Arc stability control: Arc stability needs to be maintained to avoid current interruption of steelmaking electric furnace

Electromagnetic stirring: Automatically control the stirring intensity of the molten pool to uniform temperature/composition.

Features: Alternate melting and preheating to achieve continuous production.

Operation key:

Timing synchronization: While one furnace is melting, the other furnace is preheated. (Reference technology: "Continuous Steelmaking" process flow chart)

Energy recovery: Use waste gas to preheat scrap steel, and the system automatically switches the furnace cover.

Foam slag operation:

Automatic carbon spraying to create bubbles, and monitor the slag layer thickness through sonar or pressure sensors.

Ultra-high power (UHP) mode:

Short arc high voltage operation, dynamic coordination of transformer taps and electrode adjustment is required.

Production scale: Large-scale production tends to use semi-automatic + manual operation and other electric arc furnace operation modes.

Steel grade requirements: High-alloy steel may require semi-automatic and flexible adjustment.

Energy cost: Automation can reduce power consumption by 10-20% (reference source "Energy Saving in Electric Arc Furnaces").

Environmental regulations: Automatic closed operation is easier to meet emission standards.

For steelmaking electric furnace, no matter which operation method you choose, decide according to your own needs and investment budget. The most important thing is to ensure safe operation and choose a trustworthy supplier and partner.

If you have any questions or needs about EAF, metal smelting furnaces such as melting furnaces, industrial electric furnaces and accessories, please feel free to contact us for answers and solutions.

Latest News

Energy Saving Ferrosilicon and Submerged Arc Furnace

May. 20, 2025

Different Electric Arc Furnace Operation Modes

May. 19, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province