Jun. 15, 2025

There are many options for coreless induction furnaces for sale. For example, there are industrial frequency induction furnace for steel, aluminum, zinc and copper casting equipment, and coreless medium frequency furnaces for smelting. These induction melting furnaces offer different capacities and functions to meet different industrial needs, such as smelting, heat preservation, etc. The main components of an induction furnace are inductors, furnace bodies, power supplies, capacitors and control systems, etc.

① Industrial frequency induction furnace: It is powered by a 50 or 60 Hz power supply, with a maximum furnace capacity of 100 tons.

② Triple frequency induction furnace: It is powered by a 150 or 180 Hz triple frequency generator, with a maximum furnace capacity of 20 tons.

Industrial frequency and triple frequency medium frequency furnaces are mainly used for large-capacity metal smelting and heat preservation of various cast irons and copper alloys, and can also be used for refining and heat preservation of molten steel.

③ Generator set medium frequency induction furnaces: Powered by a 500-10000 Hz generator set.

④ SCR medium frequency induction furnace: powered by 500-10000 Hz SCR inverter, with a maximum furnace capacity of 20 tons.

The latter two medium frequency induction melting furnaces are mainly used for the melting of medium and small capacity carbon steel, alloy steel, cast iron, copper, zinc and other metals.

⑤ High frequency induction furnace: powered by a tube-type 30000-300000 Hz high frequency generator, mainly used for the melting of small capacity special metals below 50 kg, and also a kind of melting equipment in the laboratory.

In the metal smelting industry, when the coreless induction furnace is sold, both industrial frequency and medium frequency are widely demanded by customers. The main difference lies in the power supply frequency:

The frequency of the industrial frequency furnace is 50Hz, and the frequency of the medium frequency furnace is 150-8000Hz.

Medium frequency induction furnaces are commonly used in cast iron production, while industrial frequency furnaces are mainly used for ferrous metal smelting. Industrial frequency induction furnace heat evenly, with less burn loss, and are easy to adjust the composition of molten iron.

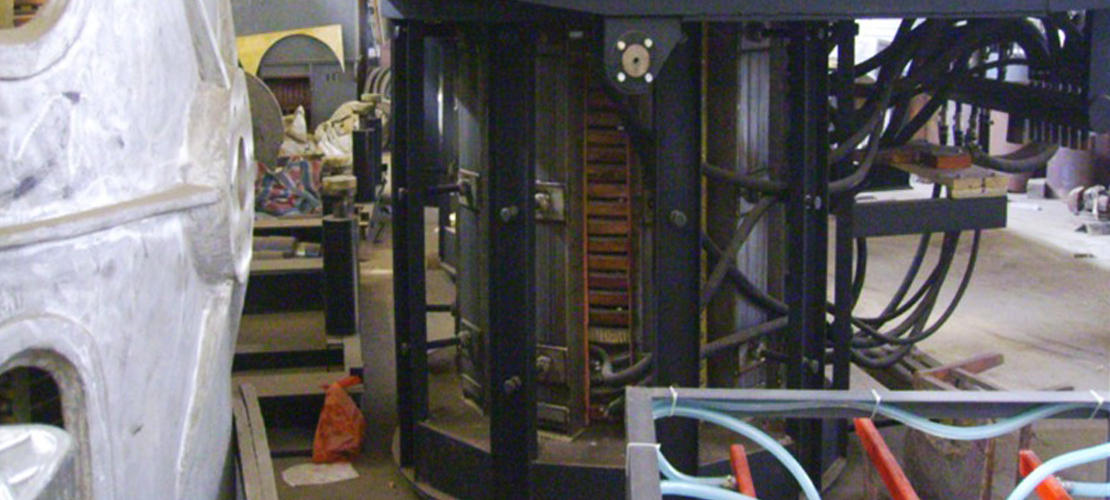

Design: The coreless medium frequency furnaces consists of a crucible and a water-cooled AC electromagnetic coil. The metal to be melted is placed in the crucible.

Working Principle: The alternating current in the coil generates a magnetic field, which produces eddy currents in the metal. These currents generate heat, melting the metal.

Application: Suitable for melting and alloying a variety of metals, including steel, iron, copper and aluminum.

High efficiency and fast melting speed.

Minimum melt loss and contamination.

Flexible processing of different metals and alloys.

Sanrui Electric Furnace coreless induction furnace for sale, which have a wide range of uses and can melt a variety of metals efficiently. Please feel free to contact us for consultation.

Latest News

What is the Difference Between a DC Arc Furnace and an AC Arc Furnace?

Jun. 16, 2025

Coreless Induction Furnace For Sale

Jun. 15, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province