Jun. 21, 2025

Converter steelmaking is an efficient steelmaking process that does not require an external heat source. It mainly uses liquid pig iron as raw material. In this process, carbon, manganese, silicon, phosphorus and other elements in the pig iron react chemically with the oxygen fed into the furnace, releasing a large amount of heat, thereby providing the required heat source for steelmaking. In addition to molten iron, converter steelmaking also adds slag materials (such as lime, quartz and fluorite, etc.), as well as scrap steel and a small amount of cold pig iron and ore, etc., to adjust and optimize the smelting process.

Converters can be divided into basic converters (lined with magnesia or dolomite) and acid converters (lined with siliceous materials) according to the different refractory materials of their lining. According to the position where the gas is blown into the furnace, the converter can be divided into three types: bottom blowing, top blowing and side blowing. In addition, converters can also be distinguished according to the gas used, such as air converters and oxygen converters. It is worth noting that acidic converters have difficulties in removing sulfur and phosphorus from pig iron, so high-quality pig iron is usually required, which limits its scope of application. In contrast, basic converters are more suitable for processing high-phosphorus pig iron and have been widely used in Western Europe. However, air-blown converter steel has not been widely promoted worldwide due to its high nitrogen content, limited raw material sources and limited scrap steel ratio.

Oxygen top-blown converter steelmaking, referred to as LD method, is known as BOF method or BOP method in the United States and is the core technology of modern steelmaking. The process involves an upright crucible-shaped furnace in which an upright water-cooled oxygen lance is inserted from the top to provide pure oxygen for blowing in the furnace. The furnace body is designed to be tiltable to adapt to different steelmaking needs.

The charge mainly includes molten iron, scrap steel and slag-making materials. At the same time, cold pig iron and iron ore can also be added in appropriate amounts. During the steelmaking process, high-pressure pure oxygen (O2 concentration reaches more than 99.5%) is blown into the molten pool through an oxygen lance to achieve oxidation removal of elements such as silicon, manganese, carbon and phosphorus. At the same time, dephosphorization and desulfurization are further carried out through slag making technology. In this way, the heat released when various elements are oxidized will heat the liquid metal in the molten pool, thereby obtaining molten steel that meets the predetermined chemical composition and temperature requirements. This method is mainly suitable for the smelting of non-alloy steel and low-alloy steel, but after refining treatment, it can also be used to smelt alloy steels such as stainless steel.

This is a steelmaking method in which oxygen is blown into the molten pool in the furnace through an oxygen nozzle at the bottom of the converter to smelt molten iron into steel. Its uniqueness lies in the relatively short and fat furnace design, the flat furnace bottom and easy disassembly and replacement. It abandons the oxygen lance system of the oxygen top blowing converter and replaces it with a tuyere, distributor system and oxygen supply system on the furnace body. The blowing process of this steelmaking method is smoother, with less splashing and smoke, and the iron oxide content in the slag is also lower. Therefore, the metal recovery rate of the oxygen bottom-blown converter is 1% to 2% higher than that of the oxygen top-blown converter. In addition, the use of powdered slag-making materials has fine particles and a large specific surface area, which increases the reaction interface and makes the slag formation faster, which is very conducive to desulfurization and dephosphorization. This method is particularly suitable for blowing medium-phosphorus pig iron, so it has been widely used in Western Europe.

Continuous steelmaking is a steelmaking method characterized by the fact that raw materials (such as molten iron and scrap steel) are continuously added from one end of the furnace, while the finished product (such as molten steel) flows continuously from the other end of the furnace. This process was conceived in the 19th century. Although it has potential advantages such as compact equipment, simple and stable process flow, various countries have tried many different methods for experiments for a long time, including trough method, spray method and foam method, but these methods have not yet been industrialized.

Mixed steelmaking is a steelmaking process in which molten steel is made in one furnace and reduced slag or reduced slag and alloy are made in another electric furnace. Subsequently, the two products are mixed by a mixing operation at a specific height. This process can be used to treat molten steel made in open-hearth furnaces, converters and electric furnaces, and can effectively improve the quality of steel. During the mixing process, the contact area between slag and steel is increased, which accelerates the chemical reaction, and also helps deoxidation, desulfurization, and adsorption and polymerization of gases and inclusions, ultimately achieving the purpose of improving the purity and quality of steel.

Compound blowing converter steelmaking is a new steelmaking technology based on top blowing and bottom blowing oxygen converter steelmaking methods, combining the advantages of both and overcoming their respective shortcomings. Its core is to introduce different gases from the bottom of the original top blowing converter, thereby optimizing the stirring effect of the molten pool.

At present, most countries in the world use this composite blowing technology, and have derived various types of composite blowing converter steelmaking processes. For example, British Steel has developed a molten pool stirring and combined blowing converter steelmaking method using air, N2 or Ar2 as bottom blowing gas and N2 for cooling at the same time - BSC-BAP method. Germany's Klöckner-Max Metallurgical Plant uses a unique KMS method to spray coal and oxygen into the molten pool from the bottom through a natural protective bottom gun. Japan's Kawasaki Steel Company mixes 30% of the total oxygen with lime powder and blows it into the molten pool from the bottom of the furnace, forming the K-BOP method. In addition, Nippon Steel has also developed an LD-OB method, which blows 10%-20% of the total oxygen from the bottom and cools the bottom nozzle with propane or natural gas. These different processes are all aimed at improving steelmaking efficiency and quality.

Since the mid-1950s, the open-hearth steelmaking process has ushered in innovation. By setting 1 to 5 water-cooled oxygen guns on the top of the melting chamber and blowing oxygen directly into the molten pool, this method significantly improves the kinetic conditions of the molten pool reaction. As a result, the thermal effect of the carbon-oxygen reaction has changed from endothermic to exothermic, while optimizing the thermal conditions. This innovation has greatly improved productivity.

Electric arc furnace steelmaking is a process that uses the thermal effect of electric arc to melt metals and other materials. In the steelmaking process, the three-phase AC electric arc furnace is the most common direct heating electric arc furnace. There is no gas in the furnace. It can create an oxidizing or reducing atmosphere according to the process requirements. Therefore, it is very suitable for smelting high-quality non-alloy steel and alloy steel.

According to the different furnace capacity per ton, the electric arc furnace can be divided into ordinary power electric arc furnace, high power electric arc furnace and ultra-high power electric arc furnace. With the transformation of electric arc furnace steelmaking to high power and ultra-high power, the smelting time can be shortened, the power consumption is reduced, the productivity is improved, and the overall cost is reduced accordingly. This change allows the electric arc furnace to be used not only as a melter, but also concentrates all refining processes in the refining device. In recent years, DC arc furnaces have developed rapidly due to their low electrode consumption, stable voltage and low noise, and are particularly suitable for smelting high-quality steel and ferroalloys.

STB method, namely Sumitomo Top and Bottom blowing process, is a steelmaking technology invented by Sumitomo Metal Corporation of Japan. It cleverly combines the dual advantages of oxygen top blowing converter steelmaking and oxygen bottom blowing converter steelmaking. This method is particularly suitable for blowing low-carbon steel, which not only significantly improves the dephosphorization efficiency, but also greatly reduces production costs. In the steelmaking process, the bottom blowing gas mainly uses O2, CO2, N2, etc. In addition, Sumitomo Metal Corporation has further innovated the STB-P method on the basis of the STB method. By spraying powder from the top, it effectively optimizes the dephosphorization conditions of high-carbon steel and has been successfully applied to the refining of stainless steel.

RH method, the full name of which is cyclic vacuum treatment, is a steelmaking technology jointly developed by Ruhrstahl and Heraeus of Germany. This technology cleverly uses the vacuum chamber and conduit to extract the molten steel and raise it to a certain height. By blowing in the inert gas Ar, the molten steel is driven into the vacuum chamber for fine treatment. The treated molten steel then flows back to the ladle through another conduit for recycling. In addition, a feeding system is also equipped above the vacuum chamber for adding alloying elements. This method has become the main means of treating molten steel in large-capacity ladles (over 80t).

RH oxygen blowing method, that is, on the basis of RH vacuum cycle degassing technology, oxygen blowing operation is introduced to increase the temperature. This technology is particularly suitable for the refining of stainless steel, because the decarburization reaction will take precedence under a reduced pressure environment. It is also effective for the refining of ordinary steel and can reduce the burden on the converter. In addition, the effect of increasing the temperature can also be achieved by adding aluminum elements.

OBM-S method, the full name of which is Oxygen Bottom Maxhutte-Scarp, is a steelmaking technology invented by the German Maxhutte-Klockner plant. It uses natural gas or propane as the cooling medium of the bottom-blowing oxygen lance, combined with the oxygen bottom-blowing converter steelmaking method, to form unique technical characteristics. In the OBM-S method, by installing a side-blowing oxygen lance on the furnace cap of the OBM oxygen bottom-blowing converter, and using the coal gas or natural gas blown into the bottom oxygen lance to preheat the scrap steel, the purpose of increasing the scrap steel ratio and optimizing the steelmaking process is achieved.

NK-CB method, full name NKK Combined Blowing System, is a steelmaking technology created by Nippon Steel Pipe Co., Ltd. in 1973. It cleverly combines top blowing and bottom blowing, that is, while blowing the top, a small amount of gas such as Ar, CO2 or N2 is blown into the bottom of the furnace, thereby strengthening the stirring of the steel slag and effectively controlling the CO partial pressure in the molten steel.

This method uses porous brick nozzles, which can not only reduce costs when refining low-carbon steel, but also help dephosphorization when producing high-carbon steel. In addition, the combination of NK-CB method and molten iron pretreatment process further improves its steelmaking efficiency and quality.

The MVOD method is an improvement on the VAD method. By adding a water-cooled oxygen gun, it has the function of oxygen blowing decarburization in a vacuum environment. Since vacuum decarburization is an exothermic reaction, there is no need to apply additional vacuum heating measures of the VAD method. Its operation process is consistent with the VOD method.

The LF method, full name Ladle Furnace, is a ladle furnace refining technology created by Japan Special Steel Company (Datong Steel Special Steel Company) in 1971. Its refining process combines argon stirring, submerged arc heating and alloy feeding system, which is a key link in the steelmaking process. This method can not only accurately control the composition and temperature of molten steel, but also effectively reduce the inclusion content and improve the utilization rate of alloy elements. Therefore, the LF furnace has become an indispensable refining equipment outside the furnace in the steelmaking process.

LD steelmaking method, full name oxygen top blowing converter steelmaking method, is an innovative technology first introduced in the industrial field by the Linz plant of Voestalpine and the Donawitz plant of the Austrian Alpine Mining and Metallurgical Company in 1952. This method is named after the initials of the two plants and has quickly been widely used around the world. In the United States, this steelmaking method is called BOF or BOP method, which is the abbreviation of Basic Oxygen Furnace or Process. The birth of oxygen top blowing converter steelmaking method has brought revolutionary changes to the steel industry.

LD-OTB method, full name LD-Oxgyen Top an Bottom Process, is a top and bottom composite blowing converter steelmaking process independently developed by the Kakogawa plant of Kobe Steel, Japan. The core of this process lies in its unique bottom blowing design, which adopts technology specially developed for single annular slit nozzle (SA nozzle), making the control range of bottom blowing gas extremely wide. During the steelmaking process, inert gas will be blown into the bottom to achieve precise control of the furnace environment.

LD-Hainaut Saubre CRM, a top-bottom composite blowing converter steelmaking process developed in Belgium for blowing high-phosphorus hot metal. The process combines LD and bottom oxygen blowing technology, and uses hydrocarbon protection nozzles to provide a new solution for high-phosphorus hot metal steelmaking.

LD-Arbed-Centre National, a steelmaking process created by the French Iron and Steel Institute. It uses top oxygen spraying lime powder, which is specially designed for blowing high-phosphorus hot metal, bringing new possibilities for steel production.

Klockner Steelmaking process is a bottom coal-powder-sprayed oxygen converter steelmaking method using 100% solid material operation. In this process, the bottom oxygen ratio is controlled in the range of 60% to 100%.

This is an electric arc furnace steelmaking method that combines bottom gas blowing technology, secondary combustion technology and coal-powder spraying technology. This technology was jointly developed by Tokyo Steelmaking Company of Japan and Kiokner of Germany. Its uniqueness lies in the ability to replace electricity with coal to achieve efficient use of energy.

Arc heating ladle degassing method, also known as vacuum arc degassing method. Its core lies in the arc heating device above the vacuum chamber, which achieves a stable degassing effect by stirring with argon in a vacuum environment. In addition, this method can effectively remove sulfur and carbon elements and allow the addition of a large amount of alloys. Its equipment mainly includes a vacuum chamber, an arc heating system, an alloy feeding device, a vacuum pumping system and a hydraulic system.

This is a vacuum treatment device developed by Dortmund Horder United Metallurgical Company of Germany. Its core components include a vacuum chamber lined with refractory materials and a conduit with a refractory lining that can be inserted into the ladle. By periodically lowering and lifting the vacuum chamber or ladle, effective treatment of molten steel can be achieved. The upper part of the device is also equipped with an alloying device and a vacuum heating and insulation device to ensure the stability and efficiency of the treatment process. However, this type of equipment is no longer newly built, and is replaced by more advanced degassing technology.

This is a method specifically for stainless steel refining, and its principle is quite similar to the AOD method. The uniqueness of this method is that it uses water vapor instead of argon for refining. This innovative technology was jointly developed by Creusot-Loire of France and Uddeholm of Sweden. Since it was put into production in 1973, it has been highly praised for its efficient and stable performance.

In the process of water vapor contacting molten steel, it will decompose and generate H2 and O2. Among them, the role of H2 is to reduce the partial pressure of CO, which helps the refining process. At the same time, since this decomposition reaction is an endothermic process, it can effectively suppress the rise in the temperature of the molten steel. However, it should be noted that the degree of chromium oxidation and burning when using the CLU method will be more serious than the AOD method, which requires special attention in actual operation.

CAS method, full name Composition adjustment by sealed argonbubb

ling, is an off-furnace refining technology carried out in an argon sealed environment, aimed at fine-tuning the alloy composition. This method pushes away the slag layer by blowing argon at the bottom of the ladle, then lowers the immersion hood and continues to blow argon, and finally adds alloy to fine-tune the composition. The advantage of the CAS method is that it can achieve precise control of the alloy composition and improve the alloy yield.

CAS-OB method, full name Composition adjustment by sealed argon bubbling with oxygen blowing, is an off-furnace refining technology that further adds an oxygen blowing gun on the basis of CAS equipment. This method can not only be used to fine-tune the alloy composition, but also has the function of adding aluminum and blowing oxygen to increase the temperature, and the heating rate is controlled at 5-13℃/min. This technology enables the molten steel temperature to be accurately maintained within the range of ±3℃, providing strong support for continuous casting production.

ASEA-SKF method, a ladle refining technology originated from Sweden, combines low-frequency electromagnetic stirring with atmospheric pressure arc heating. This technology conducts slag refining in the ladle, followed by vacuum degassing at another station, and is equipped with an oxygen gun to support oxygen decarburization under reduced pressure. In addition, the refining effect can be further enhanced by blowing argon through the porous bricks at the bottom of the ladle, and alloys are added to finely adjust the composition of the molten steel.

The AOD method, full name Argon-Oxygen Decarburisation, is a key refining technology for smelting low-carbon stainless steel. The method was successfully developed by the American Carbide Company in 1964 and was put into actual production application in 1968. Its core metallurgical principle is to use argon (Ar) to dilute carbon monoxide (CO) and reduce its partial pressure, thereby simulating a vacuum state and helping to reduce carbon elements to extremely low levels. The design of the AOD furnace is similar to that of the converter. The tuyere is set near the side wall of the furnace bottom. A mixed gas of argon and oxygen is blown into the furnace, and the raw material is molten steel produced by the primary refining furnace. The entire blowing process is divided into three stages: oxidation, reduction and refining, and has now become a key process in stainless steel production.

It covers a number of steelmaking technologies, including electroslag remelting, vacuum metallurgy, plasma metallurgy, electron beam melting and regional melting. When ordinary steelmaking processes combined with off-furnace refining cannot meet the needs of certain high-tech or special uses for extremely high purity steel, these special metallurgical methods come into being.

1. Electroslag remelting: This process uses slag resistance heat to remelt the smelted steel for the second time, also known as ESR. In this process, the consumable electrode is immersed in the slag, and the current passes through the ionized slag to generate high temperature, causing the consumable electrode to melt and form droplets. These droplets pass through the slag pool by their own weight, and enter the metal molten pool after slag washing and refining, while reducing air pollution. This technology not only improves the surface quality of the ingot, but also solidifies a remelted ingot with axial crystallization tendency and less segregation through the water cooling at the bottom of the crystallizer, thereby improving the hot working plasticity.

2. Plasma metallurgy: This process uses plasma flow as a heat source and uses a plasma gun to convert electrical energy into heat energy in a directional plasma jet. Plasma jets have the characteristics of stable arcs, concentrated heat, and can reach extremely high temperatures. The operating temperature can even reach 5000-20000℃. In addition, plasma guns can also use inert gases or reducing gases as media to meet different metallurgical needs. Plasma furnaces are suitable for smelting high-melting-point metals, active metals, and purification of metals or alloys. At the same time, plasma technology is also widely used in steel plant waste dust treatment and ferroalloy production processes.

3. Jet metallurgy: This process uses gas jets to deliver powdered materials into liquid metal to accelerate the completion of physical and chemical reactions, also known as powder spraying metallurgy. This technology is often used in molten iron pretreatment and ladle refining to achieve desulfurization, deoxidation, composition fine-tuning, and inclusion denaturation. It has a fast reaction rate and high material utilization.

4. Zone melting: This is a process that uses the difference in solubility of impurity elements in the liquid and solid phases to refine metals. By slowly moving the liquid area, the impurities will be redistributed and driven to the right end. After repeated many times, the metal on the left end can reach high purity.

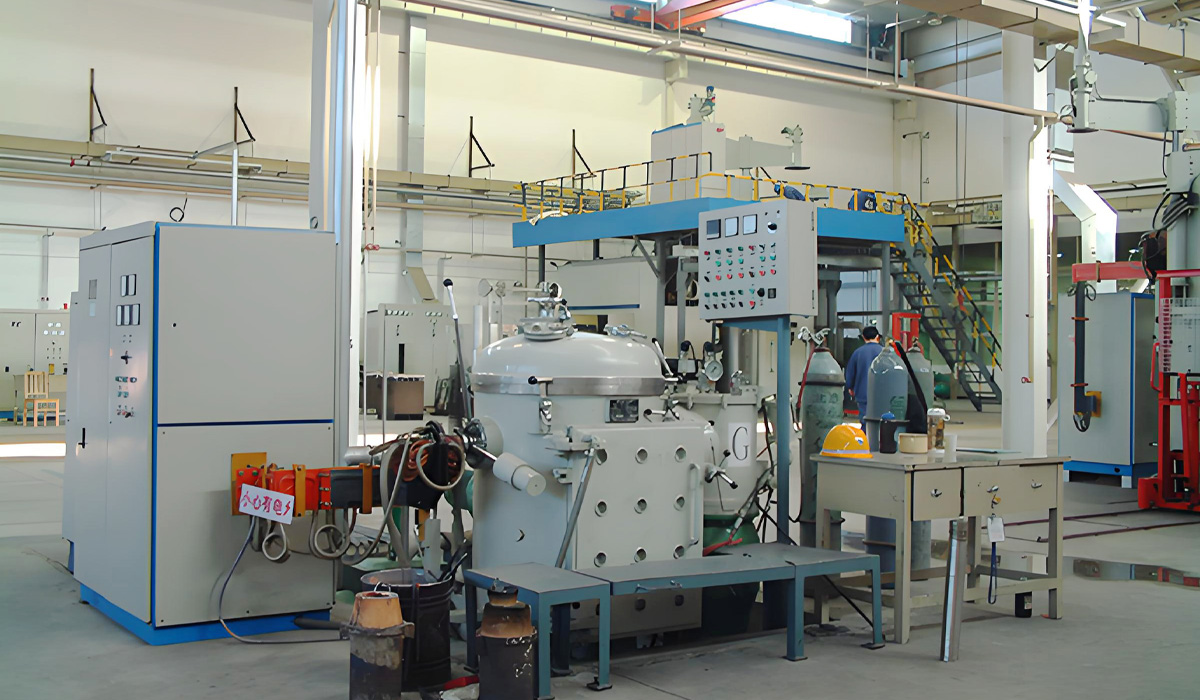

5. Vacuum metallurgy: The metallurgical process carried out under conditions of less than 0.1MPa to ultra-high vacuum is called vacuum metallurgy. It includes multiple links such as refining, smelting, remelting, refining, forming and heat treatment of metals and alloys. The purpose of this technology is to reduce the gas phase contamination of metals, reduce the content of gas or volatile impurities dissolved in metals, promote chemical reactions with gaseous products, and avoid pollution caused by refractory containers. It adapts to the production needs of high-performance metal materials and new metal materials. With the growth of production demand for high-performance and new metal materials such as electrothermal materials, electrical alloys, soft magnetic alloys and high-temperature nickel-based alloys, various vacuum melting methods such as vacuum resistance melting and vacuum induction melting have been developed.

6. Vacuum arc melting: a process of remelting metals and alloys by arc heating in a vacuum environment, referred to as the VAR method. The process involves a water-cooled copper crucible as the positive electrode, a consumable electrode connected to a dummy electrode as the negative electrode, and the introduction of a low-voltage DC current to induce an arc between the electrode and the bottom of the crucible. With the help of the heat of the arc, the metals and alloys are remelted. By controlling the electrode descent speed, a remelted steel ingot with uniform composition, dense structure, high purity and less segregation can be obtained. This technology is particularly suitable for remelting active metals, heat-resistant and refractory metals, as well as high-temperature alloys and special steels and other demanding applications.

7. Vacuum electron beam melting: a method of bombarding the smelted material with an electron beam emitted by an electron gun under a high vacuum degree, so that it melts and then drips into a water-cooled copper crystallizer to solidify into an ingot. This method can adjust the energy distribution and control the melting speed to ensure the high purity of the material. It is particularly suitable for melting metals such as tungsten and molybdenum and their alloys, high-grade alloy steels, high-temperature alloys and ultra-pure metals.

8. Vacuum resistance melting: In a vacuum environment, metals and alloys are melted by the heat generated by the current in the conductor. This method usually adopts indirect heating, and the electric heating body transfers heat to the material in the furnace. The atmosphere in the furnace can be selected as inert or protective according to the needs. The vacuum resistance furnace can be designed as a melting furnace or as a heat treatment furnace.

9. Vacuum induction melting: In vacuum conditions, metals and alloys are melted by the induction electrothermal effect. The power supply frequency is selected according to the charge and capacity, including high frequency, medium frequency and industrial frequency. Induction furnaces are divided into two types: cored and coreless. The former has high electrothermal efficiency but is suitable for continuous melting of a single variety, and the latter has high melting temperature but is suitable for melting special steels and nickel-based alloys. This technology has been widely used in the production of high-temperature alloys, high-strength steels and ultra-high-strength steels.

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province