May. 28, 2025

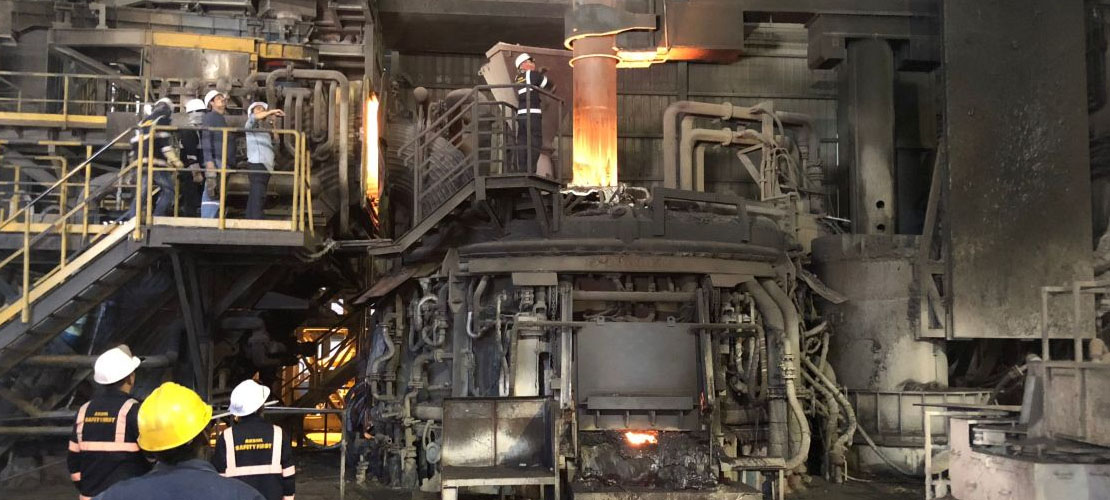

Electric arc furnace carbon oxygen gun is a mechanical process for blowing oxygen and spraying carbon in electric furnace steelmaking, replacing the traditional furnace door technique of blowing oxygen and adding carbon powder. According to user needs, this system can be controlled by various techniques, PLC, or fully automated by PLC+upper computer. The use of this system in electric furnace steelmaking production can achieve the goals of increasing production, reducing consumption, energy conservation, and environmental protection.

The main materials for electric arc furnaces are solid scrap steel mixed with alloy materials, pig iron used to adjust carbon content, etc. Direct reduced iron or a portion of hot iron can also be used, with a wide range of material choices; Therefore, except for some ultra-low carbon types of steel that may require special techniques such as vacuum treatment and special alloy materials, most types of steel can be exercised.

With the continuous improvement of exercise techniques and skills, the modern electric arc furnace steelmaking profession has become one of the important methods to enhance electric furnace training by spraying carbon and blowing oxygen in order to improve exercise power and reduce costs. At the same time, the addition of carbon powder and oxygen can fully utilize the chemical energy in the furnace for the second incineration, and significantly reduce energy consumption. There are two types of furnace door carbon oxygen guns: consumable carbon oxygen guns and water-cooled carbon oxygen guns.

The new carbon oxygen lance nozzle for electric furnace steelmaking involves blowing oxygen and spraying carbon equipment for electric furnace steelmaking. It is composed of a cooling water ring seam, a carbon spray hole, an oxygen spray ring seam, and an oxygen spray hole. Its characteristic is that the carbon spray hole is surrounded by the oxygen spray ring seam, and there is a certain degree of pain relative to the axis. The oxygen spray hole is Laval shaped, and both the carbon spray hole and the oxygen spray hole use one cooling water ring seam for cooling. The characteristics are: reasonable and compact structure, easy processing and manufacturing, significant improvement in production power, no need to modify the oxygen and carbon supply system of the original mother child carbon oxygen gun, improved cooling environment of the gun body, and significantly improved the life of the gun body.

The influence of the angle (inclination angle) between the oxygen lance and the horizontal line, as well as the rotation angle of the oxygen lance, on the mixing time of the molten pool is obtained by measuring the residence time of the tracer particles in the model. At present, the chemical energy generated by oxygen in electric furnace steelmaking accounts for a significant share of the energy input to the electric furnace, reaching 20% to 30%. Especially after using hot charged iron in electric furnaces, the proportion of chemical energy reaches over 40% of the total energy, which is equivalent to nearly doubling the energy input of electric furnaces. The large amount of oxygen input has become a major feature of modern electric arc furnace steelmaking processes.

Latest News

What is the Difference Between a DC Arc Furnace and an AC Arc Furnace?

Jun. 16, 2025

Coreless Induction Furnace For Sale

Jun. 15, 2025

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province