May. 17, 2025

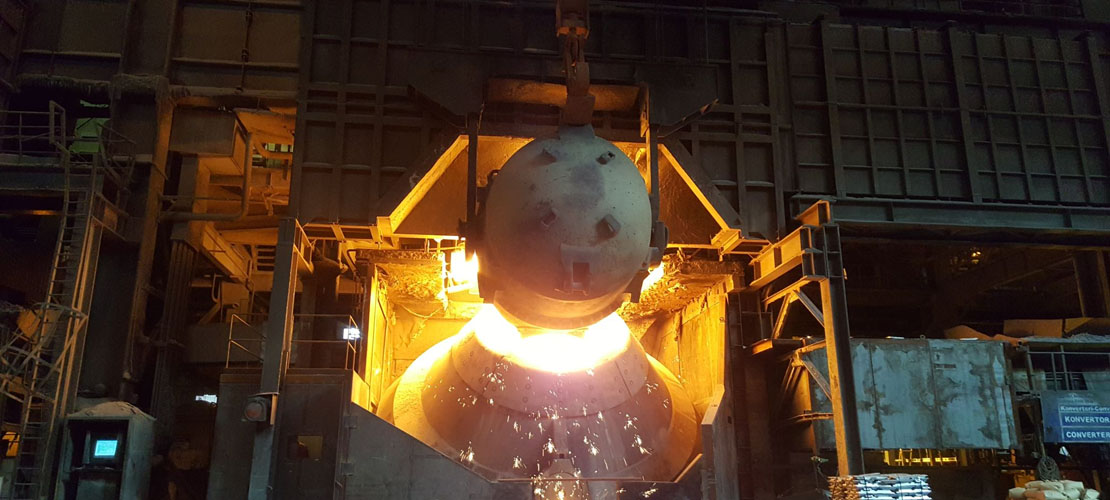

The steelmaking process utilizing the basic arc furnace oxidation method is characterized by the efficient smelting of steel scrap as the primary raw material, facilitated by electrical heating. The core process encompasses seven stages: raw material preparation, furnace repair, batching and charging, melting phase, oxidation phase, reduction phase, and tapping.

Scrap steel serves as the primary raw material for electric arc furnace (EAF) steelmaking. Its quality directly impacts molten steel composition, production safety, and cost efficiency. Specific requirements include:

Cleanliness: Scrap must exhibit minimal surface rust and be free of sludge or oil contamination. Pollutants reduce electrical conductivity, prolong melting time, increase hydrogen content in molten steel, and hinder dephosphorization during oxidation.

Restrictions on Harmful Elements: Prohibit mixing with non-ferrous metals such as lead (deposits at furnace bottom, causing leakage), tin/arsenic/copper (inducing hot brittleness), and zinc (volatilizes, contaminating emissions).

Safety Protocols: Exclude sealed containers, flammable/explosive substances, or toxic materials.

Composition Control: Classify scrap by chemical composition; strictly regulate sulfur and phosphorus levels.

Dimensional Standards: Cross-sectional area ≤300mm×300mm; maximum length ≤350mm to optimize charge density and melting efficiency.

Post each heat, the furnace lining requires maintenance to preserve structural integrity and safety:

High-Temperature Rapid Repair: Immediately after tapping, remove residual slag and apply magnesia-based materials using a "thin-layer" principle to maintain original furnace geometry.

Curing via Electrode Baking: Premix repair materials and bake with electrodes for ≥30 minutes; extend duration for large-scale repairs.

Burdening Principles:

Precise calculation of charge ratios; combine scrap of varying sizes (large, medium, small) to optimize density.

Integrate low-carbon scrap and refractory materials for composition control.

Charging Sequence:

Layer 2% lime (relative to charge weight) at the furnace base to form early slag for dephosphorization and gas reduction.

Place 50% small-sized scrap at the bottom, followed by large-sized/low-carbon scrap and refractory materials in the central zone, interspersed with medium-sized scrap. Top with remaining small scrap.

Melting Stage:

Electrodes generate arcs to melt the charge. Oxygen lancing accelerates heating, reduces gas content, and lowers phosphorus levels.

Oxidation Stage:

Introduce oxygen or iron ore to oxidize carbon and phosphorus, forming CO bubbles for degassing. High-basicity slag (CaO/SiO₂ ratio: 2–3) enhances dephosphorization.

Post-oxidation slag removal initiates reduction for deoxidation, desulfurization, and composition adjustment:

Pre-Deoxidation and Slag Formation:

Add ferromanganese for preliminary deoxidation. Create thin slag (2–3% of molten steel weight) using lime:fluorite:silica brick fragments (4:1:1 ratio) to minimize gas absorption.

Reduction Reactions:

Introduce carbon powder to form white slag under sealed conditions.

Supplement slag modifiers (lime:fluorite:carbon=4:1:1) every 6–8 minutes to maintain fluidity and deoxidizing capacity.

Ensure ≥15 minutes of reduction; finalize composition with ferrosilicon and ferrochromium additions.

Final Deoxidation: Inject aluminum at 0.1–0.15% of molten steel weight for terminal deoxidation.

Composition and Temperature: Meet internal standards; molten steel temperature exceeds target by 10–20°C.

Equipment Readiness:

Clean, dry tap hole; preheat ladle to dull red. Add 2.0 kg/heat of Si-Al-Ba and 1 kg/ton of rare-earth ferrosilicon 15 minutes before tapping.

Holding Process:

Sample molten steel post-tapping; maintain ≥5 minutes of holding time to ensure purity and control initial casting temperature ≤ steel grade limits.

The alkaline EAF oxidation method integrates melting-oxidation synergy and reduction refining, achieving:

Enhanced Controllability: Adjustable slag and gas phases for oxidation/reduction environments.

Reduced Alloy Burn-off: Ideal for high-grade steels containing chromium/nickel.

Superior Metallurgical Quality: Dense microstructure, improved mechanical properties, and surface finish, yielding significant economic returns.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province