Dec. 25, 2024

Electric arc furnace silicon production mainly relies on the high temperature generated by the electric arc between the graphite electrode and the metal bath, usually reaching about 2200K. This high temperature allows the reduction reaction of silicon to proceed, and ultimately produces silicon.

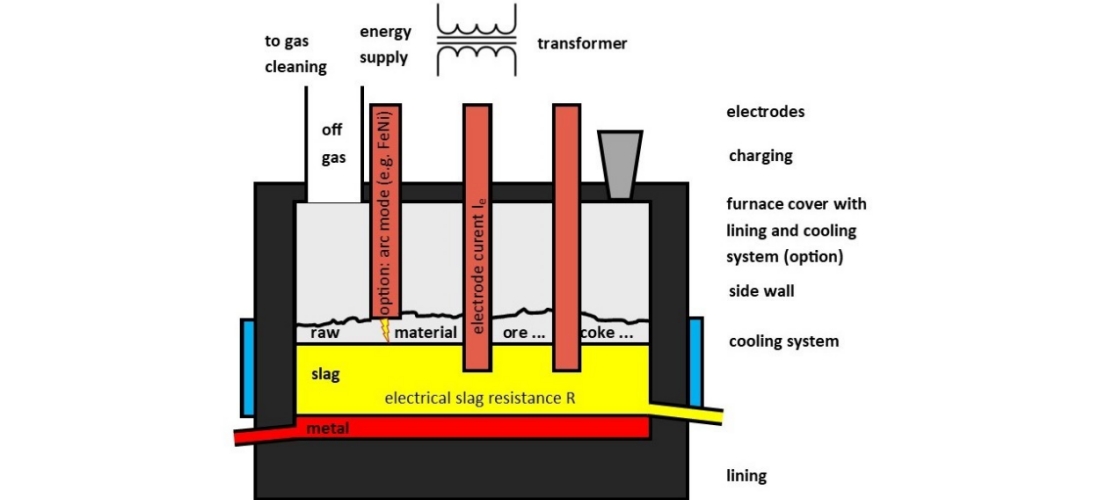

Although electric arc furnaces can be used for silicon production, the more commonly used in industry is the submerged arc furnace because it can provide the required heat to support the reaction. Therefore, the submerged arc furnace silicon production process needs to be understood.

The production process of silicon smelting electric furnace mainly includes the following steps:

The main raw materials for silicon smelting furnace production are quartz sand (SiO₂) and reducing agent, usually coke (C) or charcoal (C). In addition, a certain amount of flux needs to be added.

Put the prepared raw materials into the silicon smelting electric furnace. In the submerged arc furnaces, a high-temperature arc is generated by electric current, and the temperature can reach more than 1600°C, which prompts the silicon dioxide in the quartz to react with the reducing agent.

At extremely high temperatures, SiO₂ and C undergo a reduction reaction to produce molten silicon (Si) and carbon monoxide (CO) gas

The molten silicon gathers at the bottom of the electric furnace and then solidifies through a cooling process to form block or granular silicon ingots.

Once cooling and solidification are completed, the silicon blocks can be removed from the furnace for subsequent crushing, screening and packaging.

Waste gases such as carbon monoxide generated during the production process need to be treated to reduce the impact on the environment.

The final product needs to be quality inspected to ensure that its chemical composition and physical properties meet industrial standards.

The entire process of electric arc furnace silicon production requires strict control of temperature, raw material ratio, etc. to improve the yield and quality of silicon. If you have specific questions about silicon smelting furnace or need more detailed information, please feel free to contact us.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province