Dec. 23, 2024

With the development of industrialization, steel, as an important industrial raw material, has been widely used in various fields. As an efficient and environmentally friendly way of producing steel, DC arc furnace steelmaking technology has gradually attracted people's attention and favor. This article will introduce and analyze DC arc furnace steelmaking technology.

DC arc furnace steelmaking technology is melting and smelting metal materials using DC arc as a heat source.

Compared with traditional blast furnace steelmaking technology, DC arc furnace steelmaking technology has the following advantages:

First, the energy utilization rate of DC arc furnace is high, and the furnace temperature can reach more than 3000℃, which can better meet the high-temperature requirements of modern industry;

Second, the operation flexibility of DC arc furnace is strong, and the furnace temperature and smelting process can be adjusted as needed to obtain higher-quality steel;

In addition, the DC arc furnace steelmaking process does not require the use of traditional energy such as coal, which reduces environmental pollution and energy consumption and meets the requirements of modern society for environmental protection and sustainable development.

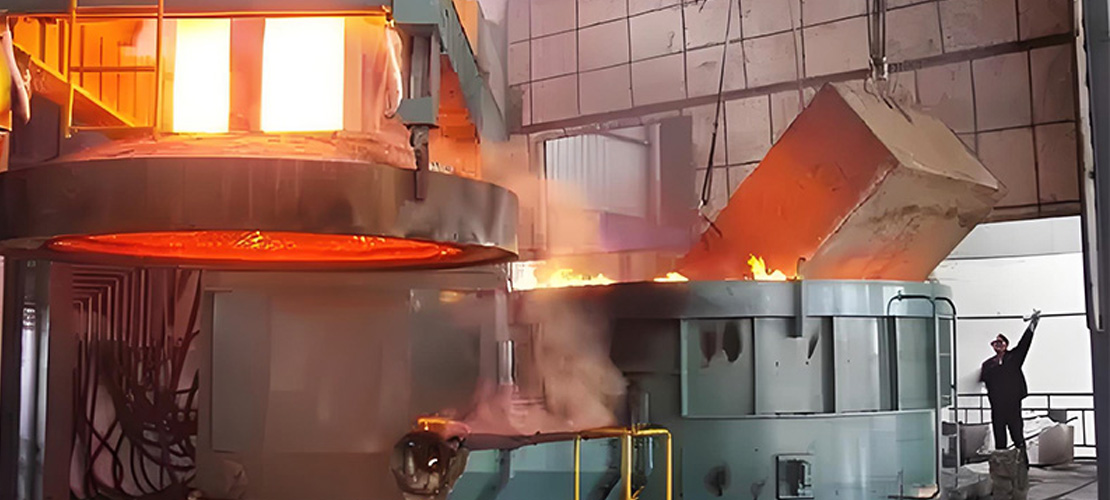

The core of DC arc furnace steelmaking technology is the arc combustion process. In a DC electric arc furnace, the arc generated by the electrode forms a high-temperature area in the furnace, and the metal material is melted and smelted at high temperatures. During the arc combustion process, the arc temperature is high and the energy is concentrated, which can quickly melt the metal material. At the same time, the high-temperature gas generated can quickly discharge impurities and oxides in the furnace, thereby improving the purity and quality of the steel.

The main equipment of DC electric arc furnace steelmaking technology includes the arc furnace body, electrode, arc combustion system, power system, and control system. The arc furnace body is the most important part of the entire steelmaking process, and its structure and material selection have an important influence on the steelmaking effect.

At present, DC electric arc furnaces mainly use water-cooled wall structures, which can effectively reduce the furnace temperature and extend the life of the equipment. Electrodes are key components for generating arcs. Carbon electrodes or non-carbon electrodes are usually used, which can withstand high temperatures and high currents. The arc combustion system is an important part of regulating the temperature of the arc furnace and the smelting process. By controlling the electrode spacing and arc current, the furnace temperature can be accurately controlled.

DC electric arc furnace steelmaking technology can be applied to a variety of steel production processes, including scrap steel recycling and refining, alloy steel and special steel production, etc. In the process of scrap steel recycling and refining, the DC electric arc furnace can quickly melt the scrap steel and remove impurities and non-metallic inclusions through processes such as oxygen blowing to obtain high-quality recycled steel. In the production of alloy steel and special steel, the DC electric arc furnace can achieve precise control of steel properties by adjusting the furnace temperature and alloy composition to meet the needs of special steel in different fields.

However, there are also some challenges and problems in DC electric arc furnace steelmaking technology. First, the investment in DC electric arc furnace equipment is large, requiring a large amount of electric energy support, and has high requirements for the power system. Secondly, the smoke and exhaust gas generated during the smelting process of the DC electric arc furnace cause certain environmental pollution, and appropriate emission measures need to be taken. In addition, the DC electric arc furnace has high operating technology requirements and requires certain technical personnel to operate and maintain it.

DC electric arc furnace steelmaking technology has broad application prospects as an efficient and environmentally friendly steel production method. With the continuous advancement and improvement of technology, I believe that DC arc furnace steelmaking technology will play an increasingly important role in the steel industry and make greater contributions to industrial development and social progress.

Latest News

Latest Products

Customized metallurgical machinery and equipment range: Electric Arc Furnace, Submerged Arc Furnace, LF Refining Furnace, Vacuum Furnace, Induction Furnace, Dust Remove System, Water Treatment Equipment, etc. Providing the most advanced equipment integration services, metallurgical equipment can be customized according to different needs of customers, and production capacity can be adjusted according to customer requirements.

Electric Arc Furnace

Submerged Arc Furnace

LF Refining Furnace

VD / VOD Vacuum Refining Furnace

Induction Furnace

Furnace Accessories

Navigation

E-mail: anna@srfurnace.com

Tel: +86 159 2955 5868

WhatsApp: +86 159 2955 5868

Add:

Room 102, Building 7A, Free Trade Xintiandi, Fengdong Avenue, Fengdong New Town, Xi'an City, Shaanxi Province